Sets new standards in pump technology

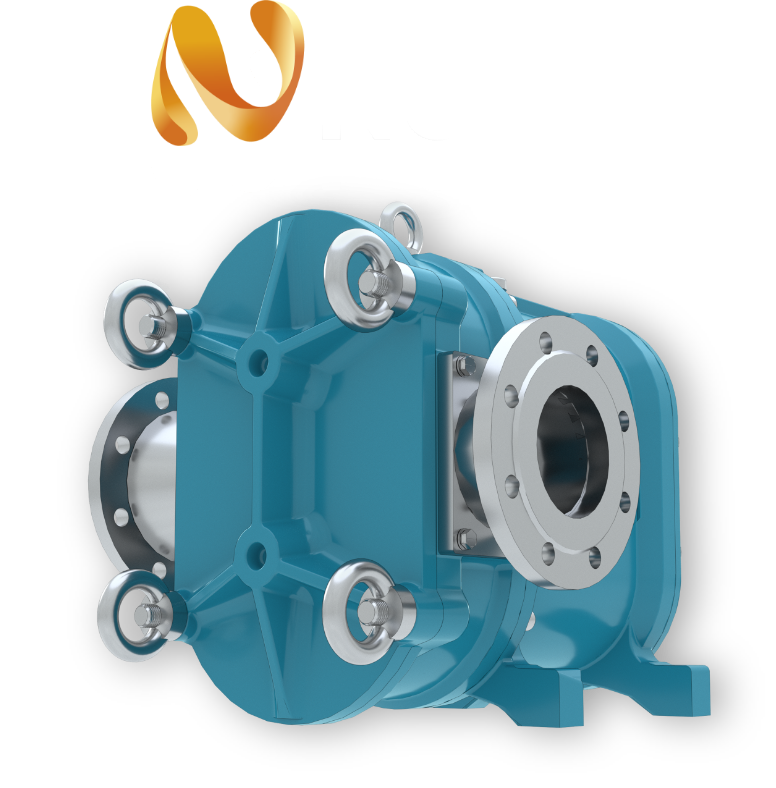

The BLUEline Nova rotary lobe pump sets new standards in pump technology and achieves unrivaled volumetric efficiencies.

The newly developed DIUS rotors in the flow-optimized pump chamber combined with an optimized pump gear unit ensure perfectly smooth running even at high pressures.

Made for one another

The development of the BLUEline NOVA pump has benefited from our experience of more than 30 years in pump manufacturing. With the help of computer flow simulations and physical test bench hours, we were able to improve the pumps even further.

To this end, the geometries of the pump chamber and the rotors were perfectly matched. The result: A volumetric efficiency that has never been achieved before combined with perfectly smooth running even at high pressures.

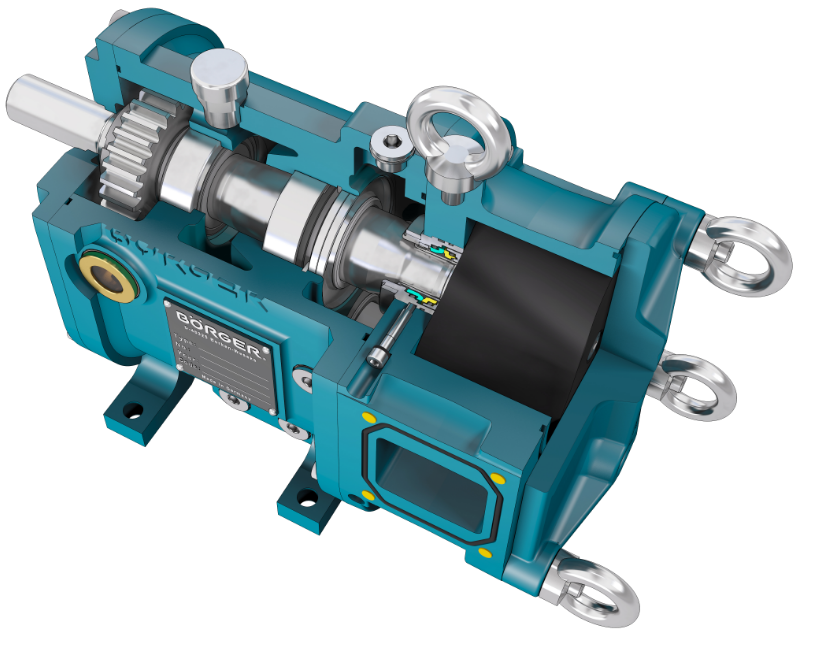

The DIUS

rotor

The newly developed one-piece DIUS rotor ensures an almost pulsation-free pumping even at high pressures. The wide sealing surface prevents a backflow of the medium and guarantees a volumetric efficiency never achieved before as well as an optimized suction performance.

Whether made of stainless steel or elastomer, the DIUS rotor does not need a cover disk. Integrated O-rings prevent that the basic core of the elastomer rotor comes into contact with the pumped medium. The shaft remains unwetted – for longest service life and simple cleaning.

BluelineNova Clean

The "clean" version of the BLUEline Nova has been designed for conveying pure, non-abrasive media. A casing protection.is not required. The pump with minimum dead space can be cleaned according to the hygiene procedures CIP (Cleaning-In-Place) and SIP (Sterilizing-In-Place).

For pure media

Blueline Nova Clean

Large seal chamber

The large seal chamber provides space for different sealing systems. Whether for quenching, flushing or buffering – the sealing system is adjusted perfectly to the requirements of the pumped medium. This ensures the longest service life and highest productivity.

In addition to the tried and tested Börger seals, special seals of other manufacturers can be used upon request.

At a glance & performance data

-

with or without casing protection

-

volumetric efficiency that could not be achieved before thanks to the perfect rotor-casing combination

-

almost pulsation-free, gentle pumping of sensitive media

-

large intermediate chamber for maximum choice of sealing systems

-

smooth running even at high pressures

| Pump size BLUEline NOVA | Speed in rpm | Flow rate | Pressure | Temp. | ||||||

| Min. | Max. | Min. | Max. | Max. | Max. | |||||

| [UpM] | [UpM] | (m3/h) | [gpm] | (m3/h) | [gpm] | [in bar] | [in psi] | (°C) | (°F) | |

| AN 040 | 1 | 800 | 0,03 | 0,1 | 20 | 95 | 10 | 145 | 200 | 392 |

| AN 070 | 1 | 800 | 0,04 | 0,2 | 35 | 155 | 8 | 115 | 200 | 392 |

| PN 100 | 1 | 800 | 0,06 | 0,3 | 50 | 210 | 12 | 175 | 200 | 392 |

| PN 160 | 1 | 800 | 0,10 | 0,4 | 75 | 340 | 12 | 175 | 200 | 392 |

| QN 230 | 1 | 600 | 0,14 | 0,6 | 85 | 365 | 8 | 115 | 200 | 392 |

| QN 300 | 1 | 600 | 0,18 | 0,8 | 110 | 475 | 8 | 115 | 200 | 392 |

BluelineNova Tough

For conveying abrasive media containing solids, we have developed the Nova tough. A radial and axial casing protection protects the pump casing. The protection plates and liners are perfectly integrated into the pump casing in a flow-optimized design. Thanks to an innovative fastening system, also the "tough" version of the Nova pump ensures excellent efficiency. In case of wear, the casing protection is replaced quickly and easily thanks to the MIP® design (Maintenance in Place).

For abrasive media

Blueline Nova Tough

Customized.

Appropriate.

Durable.

Design compliant with guidelines

All Börger pumps and pump units can be manufactured according to the European ATEX guidelines (2014/34/EU) for use in potentially explosive atmospheres.

In addition, an API-676-compliant design, production according to the FDA regulations or a technically tight pump design according to the German TA Luft requirements are possible.

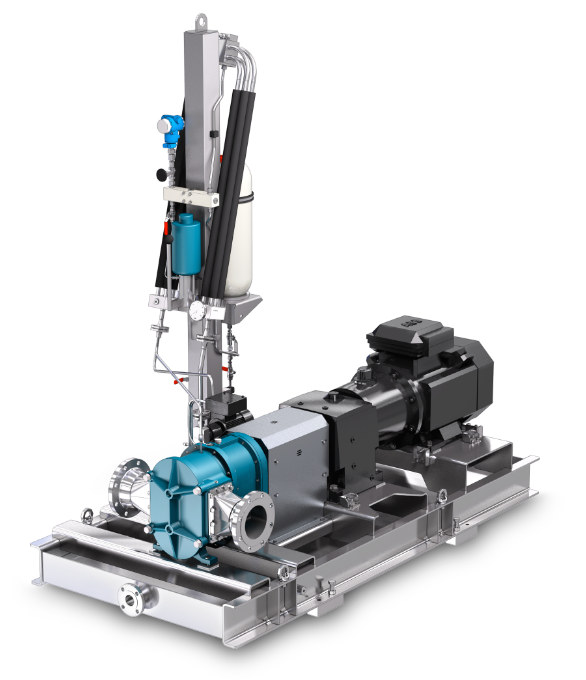

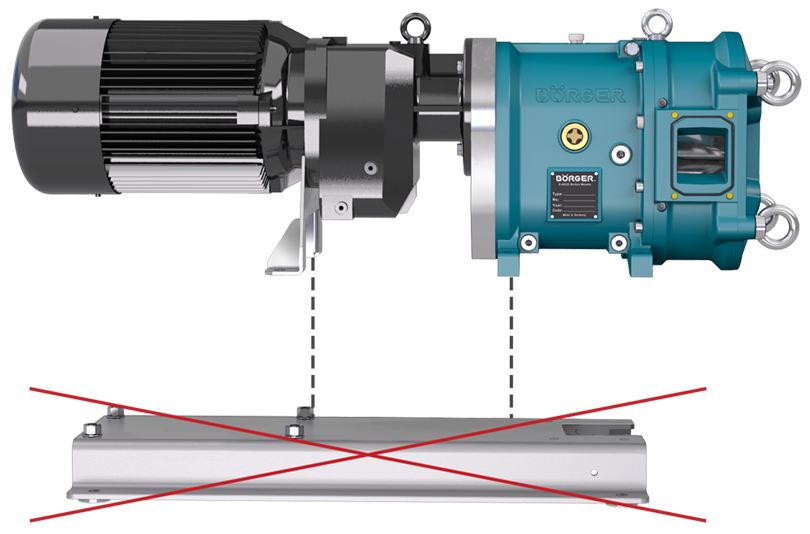

With directly flanged motor

The BLUEline Nova can be used with different drives. Upon request, the drive is directly flanged to the pump. Due to the elimination of the coupling and the base frame, the unit is even more compact.

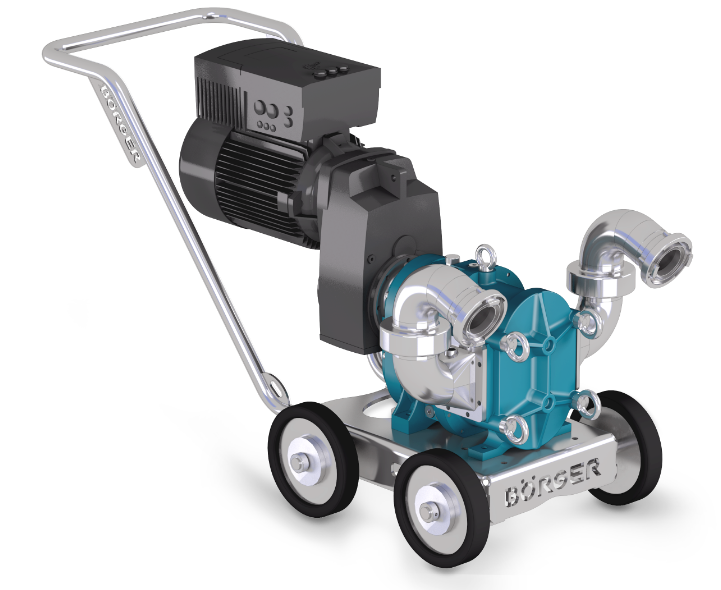

Stationary. Mobile. Submerged.

Thanks to the compact design, Börger rotary lobe pumps can be used as stationary, mobile or submerged units. High flow rate with smallest footprint.