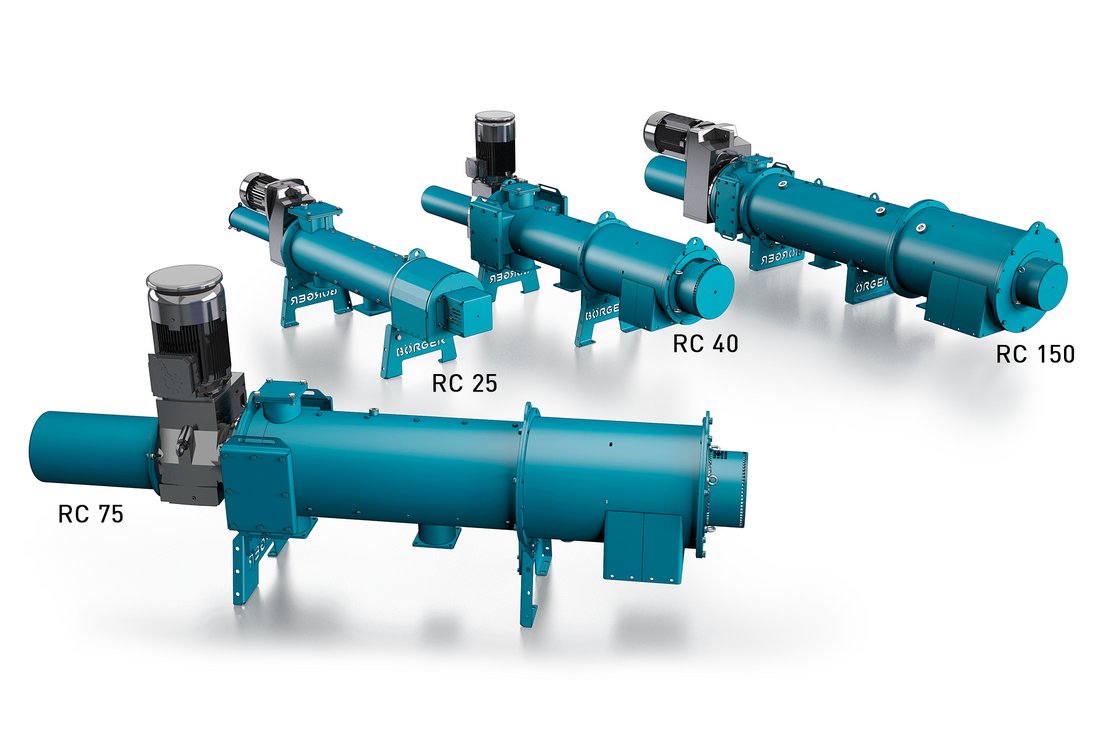

The Bioselect RC is well known for its sophisticated operating principle. With a throughput of up to 150 m³/h (660 usgpm) it is one of the most powerful separators in the world.

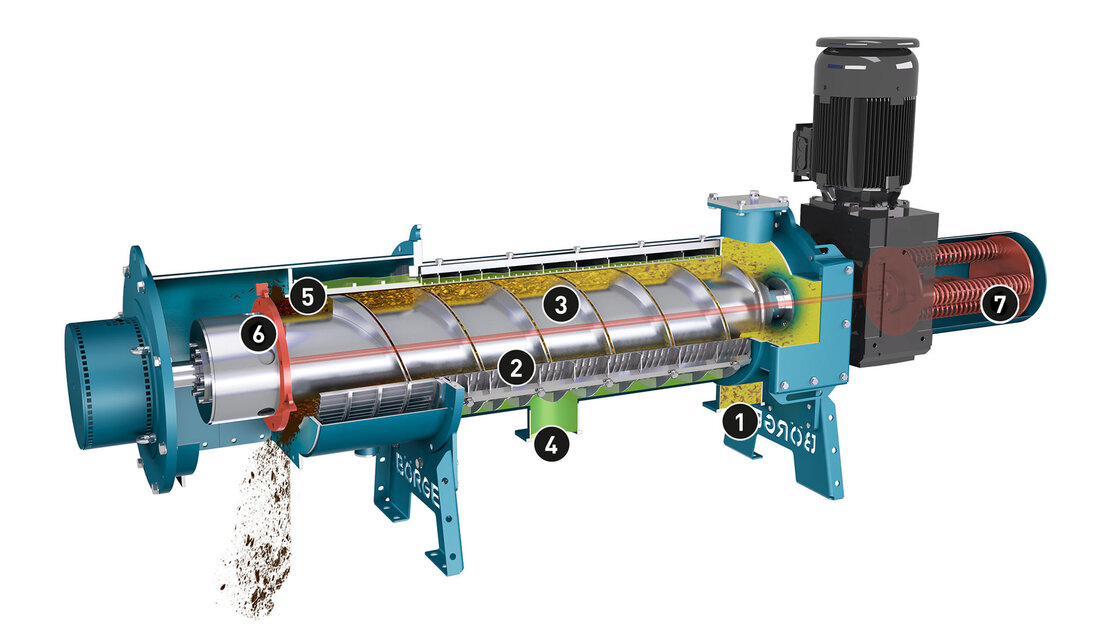

The patented Multi Disc sealing technology ensures safe operation. The level of solid content (DS content) is infinitely variable between 15 and 38 %.

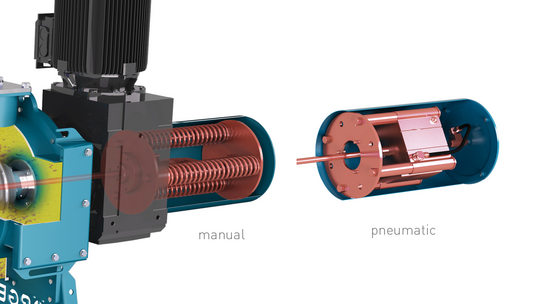

Simple and flexible adjustment of the DS content

The Easy-Shift unit provides for the closing tension of the Multi Disc. The DS content in the solids phase is set by the defined closing force.

It can be adjusted manually by means of a wrench or fully automatically (pneumatically) by means of the control unit.

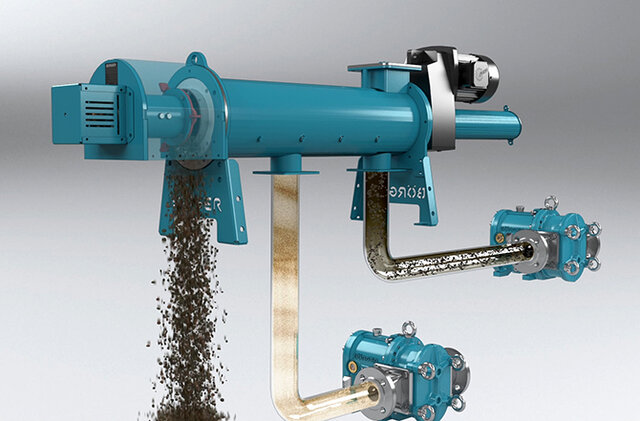

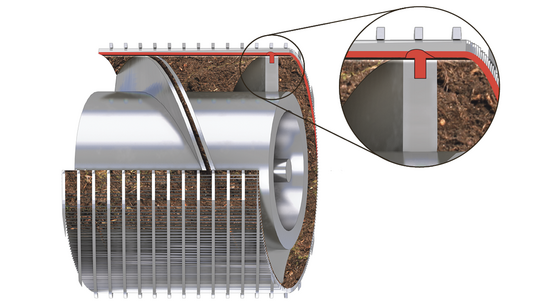

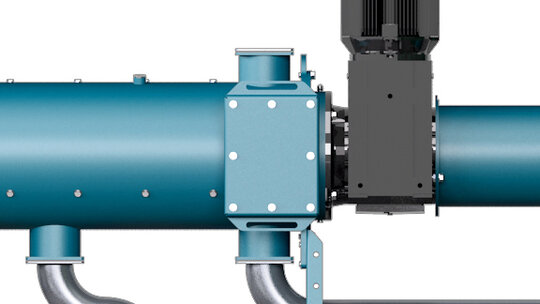

Two stages for optimum separation results

The Bioselect has two filter sections.

In the drainage area, drainage takes place without pressure. In the press channel high pressure is produced; here, the wedge wire screen has reinforced filter bars.

The two-filter system ensures maximum efficiency and the longest possible service life.

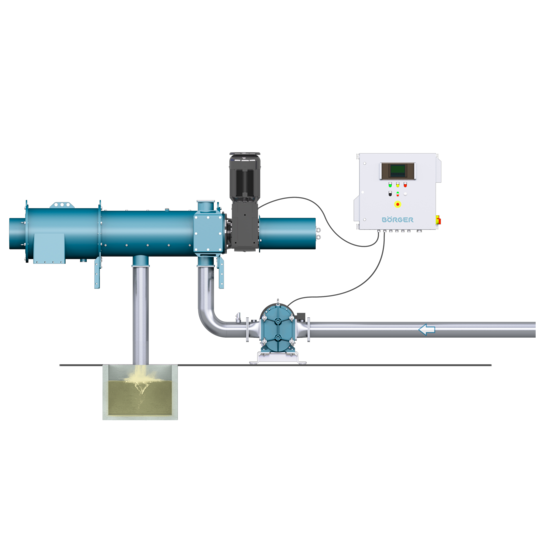

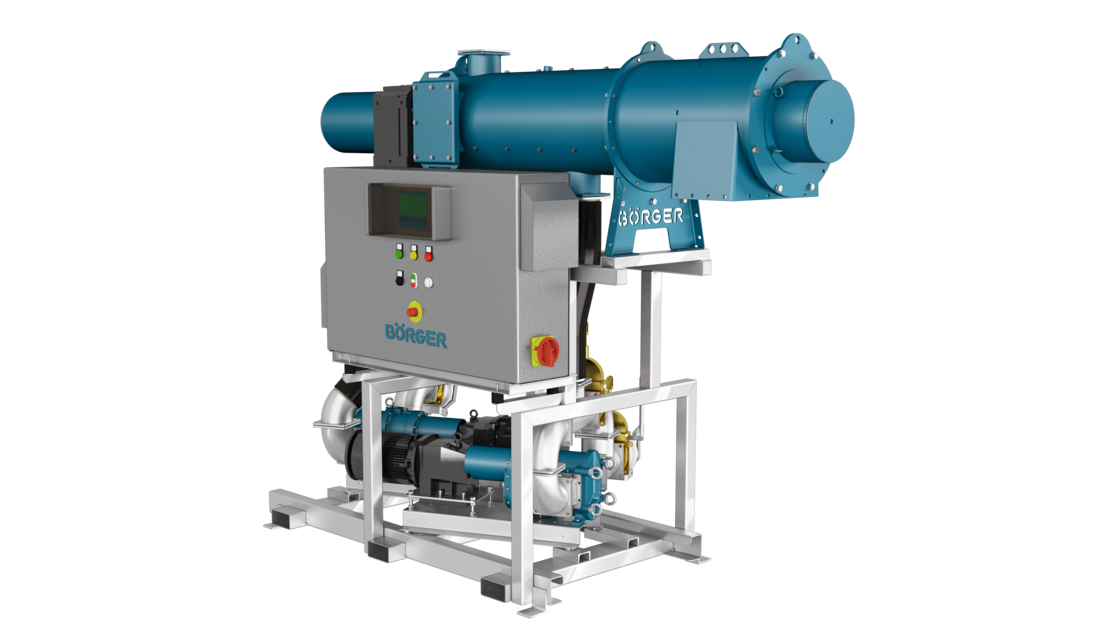

The installation options of the Bioselect are as versatile as their requirements.

Whether attached to a simple wall bracket, installed on a movable frame with an upstream macerator or as a mobile version with a conveyor belt – the application options of the Bioselect are unique. Several separators can be installed next to each other – also as mobile versions – for very high separation quantities.

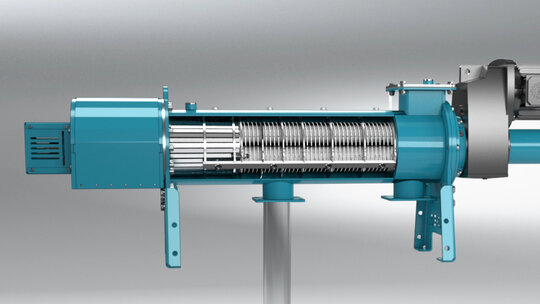

MIP® = Maintenance in Place

Simply carry out the maintenance work yourself

The operator themselves can maintain the Bioselect at the installation site.

The drive and the piping do not have to be dismantled. The auger can simply be removed from the drive shaft through the maintenance opening after a few screws have been loosened.

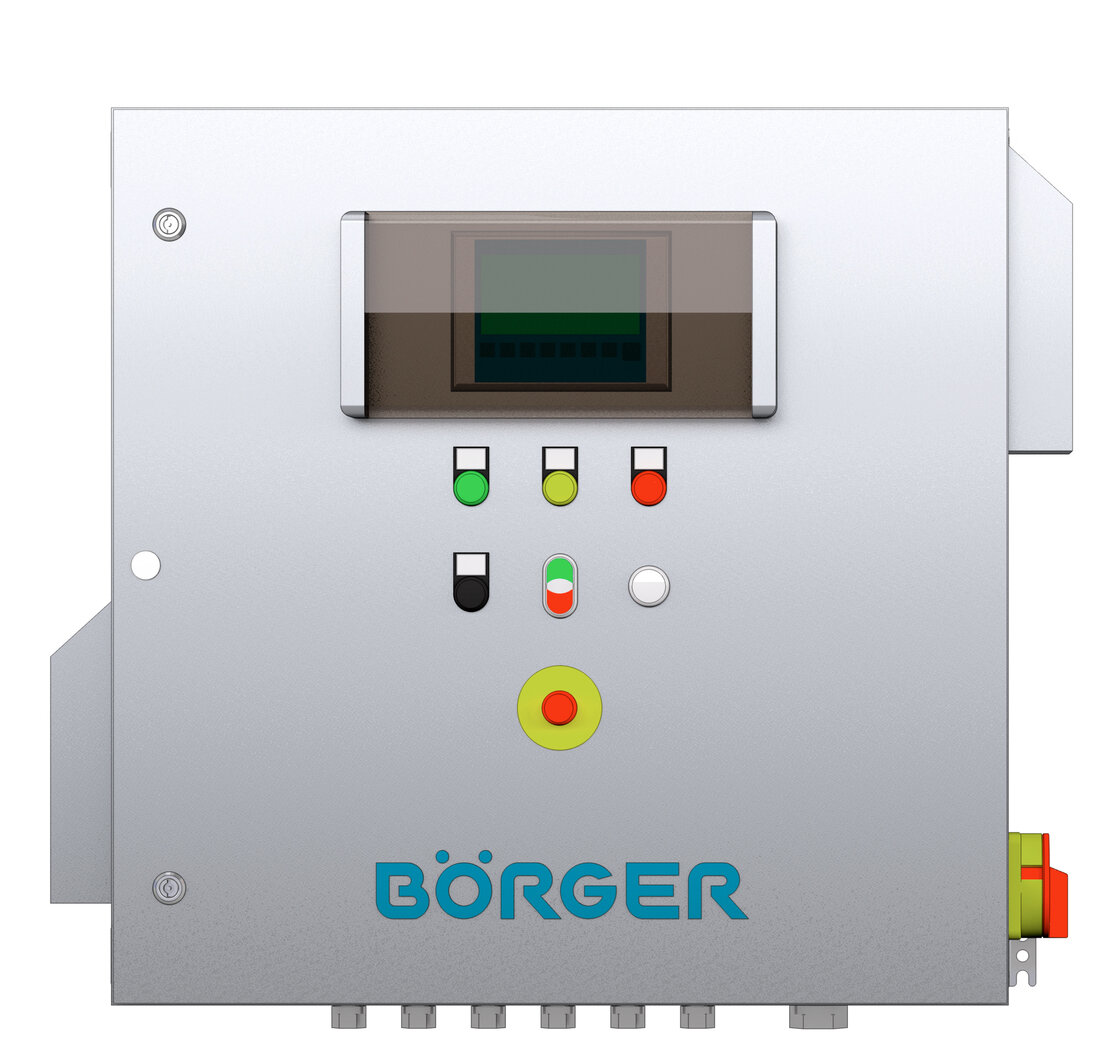

- Ideal coordination of the operation of all components (e.g. feed pump, macerator, liquid phase pump, Bioselect)

- Control of several separators possible (e.g. for mobile use)

- Perfect utilization of the Bioselect, even with changing composition of the medium being fed, by a control that ensures optimal loading (metered feeding)

- External control by operator possible via mobile communication, WLAN, DSL (remote maintenance by Börger is also possible)

- Control of pneumatic valves, conveyor belt, macerating technology

- Pneumatic adjustment of the Multi Disc (sealing disc)

- Production data acquisition (operating hours, flow rate, etc.)

- Protection of the entire system (pressure monitoring, dry run protection, function monitoring, etc.)

- Integration via bus system (Profinet, Profibus, etc.)

- Simple entry and user administration via touch display

- Further functions tailored to the customer and project are possible

- and so on

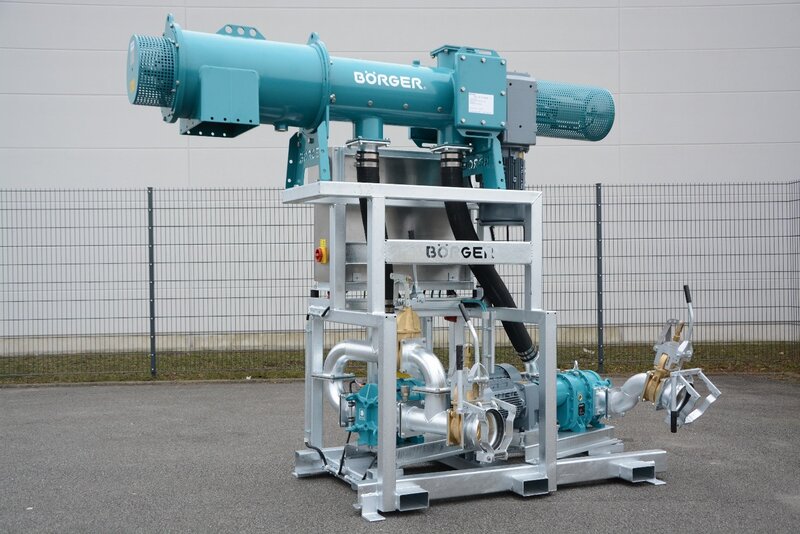

Energy efficient. User friendly. Compact.

- Large flow rates with low energy consumption

- "Everything from a single source” - separator, pump, control unit and service

- Very simple and cost-saving installation - connect the pipes, attach the power supply and it's ready to use.

- Compact, space-saving design, ideal coordination of the operation of all components (e.g. feed pump, macerator, liquid phase pump, Bioselect)

Reduction of solids in the fermenter

The operator of a biogas plant was looking for an effective separator. The plant operator had noticed that the solids content in the fermenter and the secondary fermenter was too high. Therefore, a separator was required to remove the solids from the substrate.

The customer opted for a Börger Bioselect RC 40, as he had used Börger products with excellent results and had heard about the simple but highly efficient operation of the Bioselect. A Börger PL 200 Rotary Lobe Pump conveyed the substrate from the fermenter to the Bioselect. A control unit continuously regulates the Bioselect's optimum load. The Bioselect separates the solids from the liquid phase. The solids leave the system, while the liquid phase is fed back into the fermenter in parts.

The customer is highly satisfied with the reliable Börger Bioselect. The easy handling and loose consistency of the solids were key factors in the decision.

Separation of PET parts from washing water

A plastic recycling company producing polypropylene granulates from post-consumer plastics uses two Börger Bioselect RC 75 in its plant. The two Bioselect units separate plastic residues from the washing water. Reducing the residual water content helps to save a lot of energy in the recovery process.

Before purchasing the Börger separators, the plant had already tested several devices. The Bioselect reduced the residual water content to less than 20 %, whereas a residual water content of almost 50 % was measured in the plastic residues following separation by the other devices.

The two Bioselect RC 75 are integrated in the process. Due to process-related circumstances, the process flow feeding the Bioselect cannot be regulated. A control unit automatically adjusts the speed of the separators to the volume of the feed flow and the solids content contained therein. This ensures that the two separators always operate at their optimal capacity.

The operator of the recycling plant is very satisfied with the two Börger separators as they are very energy-efficient. The customer was impressed by the high dewatering degree and the long service life of the separators.

Separation of cattle manure

Due to lack of straw, a dairy farmer was looking for an alternative bedding material for the cubicles of his 240 dairy cows. For economic reasons he opted against expensive sawdust and for a separator.

He installed a Bioselect RC 40 separator with Börger control technology and a BLUEline rotary lobe pump. The control unit coordinates the operation of the feed pump, the liquid phase pump and the separator perfectly. Automatic separation at required times can also be selected.

The DS content in the solid phase can be continuously adjusted with ease. Thus, the farmer selects a high DS content (>30 %) for use as bedding material and a low DS content (approx. 22 %) when the solid phase is to be delivered to an associated biogas plant, saving storage capacity of up to 25 %.

Using the separated solid phase as bedding material works very well. The cows like to lie on the soft material and the bacteria count in the milk continues to be at a very low level. The customer is very satisfied with his Bioselect.

Mobile Bioselect RC 150

For the separation of liquid manure and digestate an agricultural contractor uses a Bioselect RC 150 installed on a trailer. The press auger separator achieves a maximum capacity of up to 150 m³/h (660 usgpm/h), with a Börger rotary lobe pump feeding the Bioselect directly and without intermediate container. The Börger control technology continuously measures the capacity utilization of the separator and automatically varies the feeding quantity. This ensures that the separator always operates at its optimal capacity.

In order to protect the pumps and separators from impurities, the feed pump sucks the medium to be separated through a Börger Rotorrake The macerator shreds the fiber bundles while the impurities are collected in the stone trap. This guarantees long service lives of the pump and the separator.

The power required by the machines is produced by an 88 kW power generator. A 10 m (32 feet) pivotable conveyor belt transports the separated solids to the required location. The DS content in the solid phase can be continuously adjusted between 18 and 38 % by the control technology. The liquid phase is conveyed directly to the required storage location by a Börger rotary lobe pump in the closed system.

Nutrient management on a pig farm

A pig farm uses a Bioselect RC40 to adjust the solid content of pig manure. When the manure enters the separator, it has a dry solids content of approx. 5 %. The Bioselect separates the solid from the liquid phase. The DS content in the solid phase is infinitely variable up to 38 %. The customer separates with a DS content of 22 %. This way, the stackable solid phase that is passed on to a biogas plant contains large quantities of liquid.

Since the solid phase has a high nutrient concentration, the farm provides many nutrients. In addition, the farmer saves storage space. The separated liquid phase can be spread very well. It runs easily down the leaves and quickly penetrates the soil