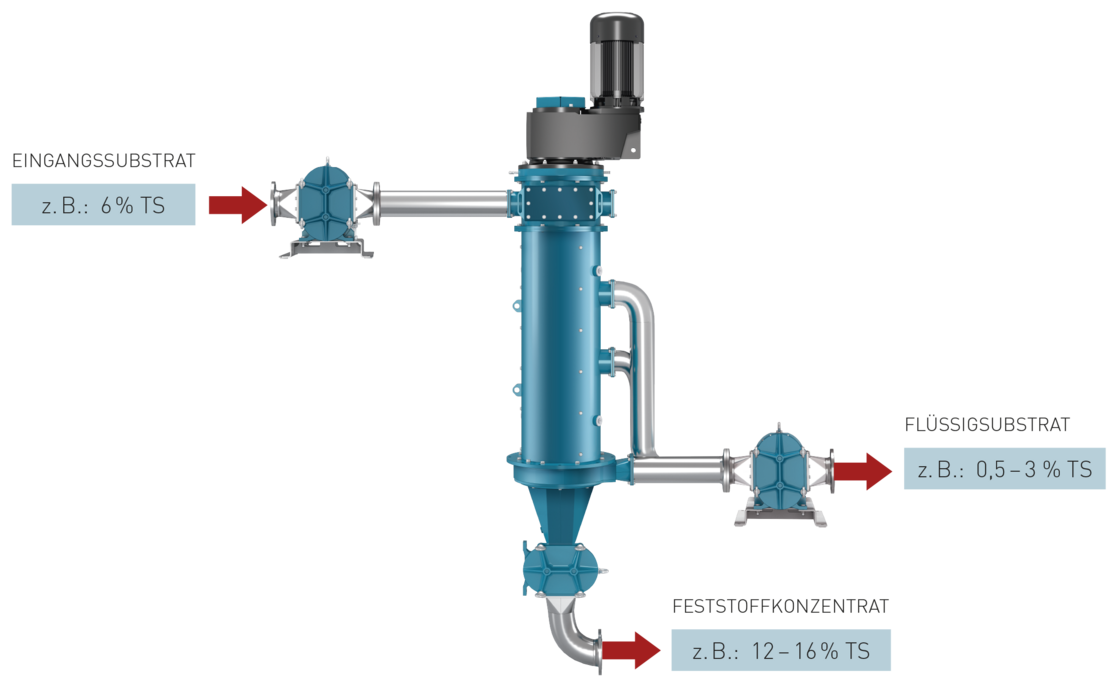

The Bioselect BS has been specially designed for the effective thickening of liquid manure and digestate. In a completely closed system, the separator thickens the inlet substrate to form a solid phase with a dry solids content of 5 to 22 %. The thickening degree is infinitely variable.

The Bioselect BS is available in three sizes.

Clever thickening process

The feed pump conveys the inlet substrate into the Bioselect. Here, the solid phase is separated from the liquid phase. The auger transports the solid phase to the thick matter pump.

The liquid phase pump conveys the liquid phase to where it is used next. By varying the flow rate of the pumps, the dry solids content (DS content) in the thick phase can be adjusted. The solid phase can still be pumped and is conveyed to the requested storage location by the thick matter pump.

This is how it works

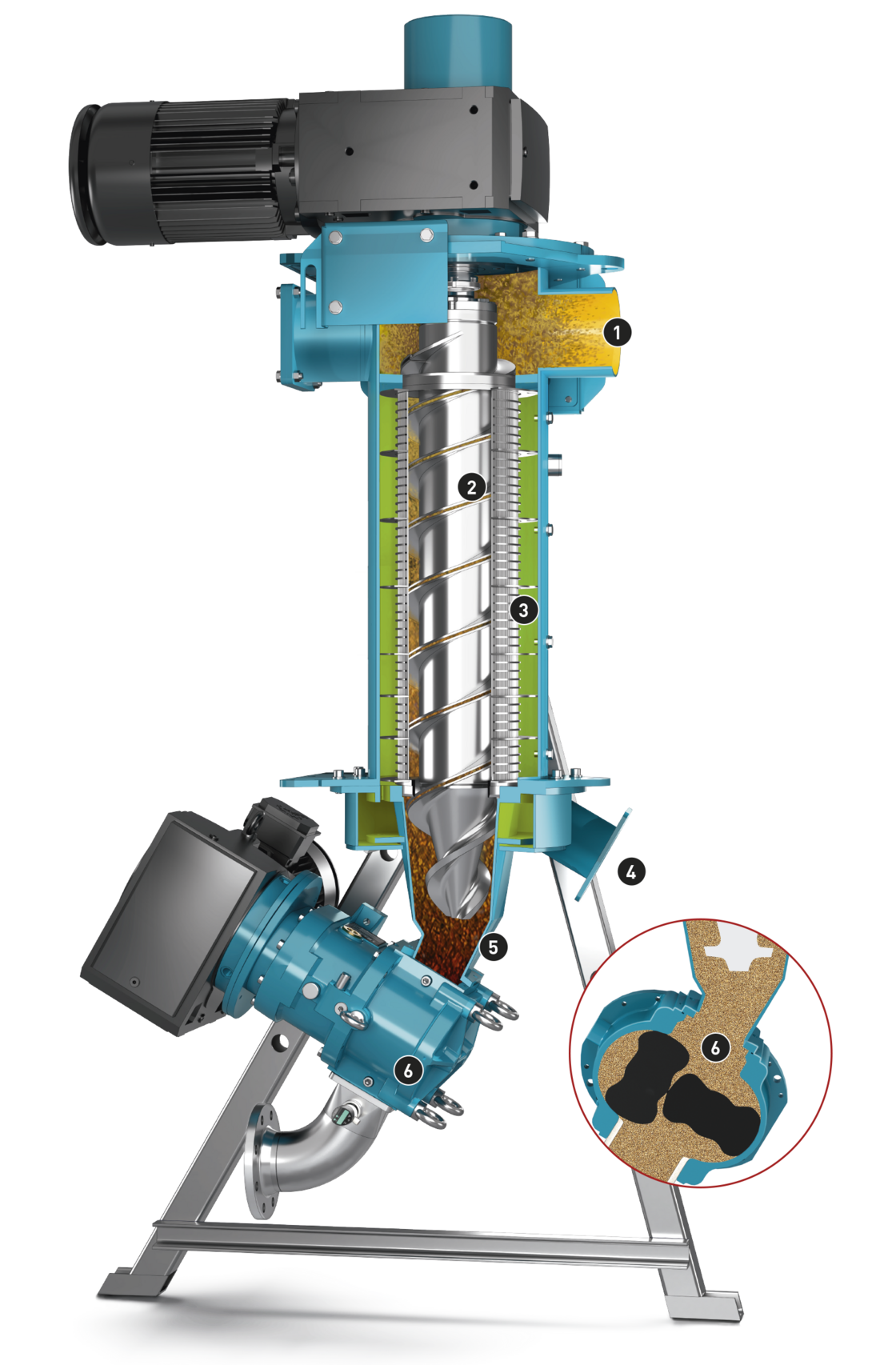

The substrate to be thickened is fed into the Bioselect BS through the inlet opening (1).

An auger (2) which is surrounded by a wedge wire screen (3) rotates inside the Bioselect. The liquid components flow through the wedge wire screen into the outer vessel area. The liquid phase is drained through the liquid outlet (4). The rotating auger unit conveys the solid components into the conical press channel (5) which ends in a thick matter pump (rotary lobe pump) (6).

The thick matter pump ensures that the thickened matter (solid phase) is reliably sealed and at the same time transfers it for further use. The thickening degree can be adapted by continuously adjusting the pump speed.

One for all

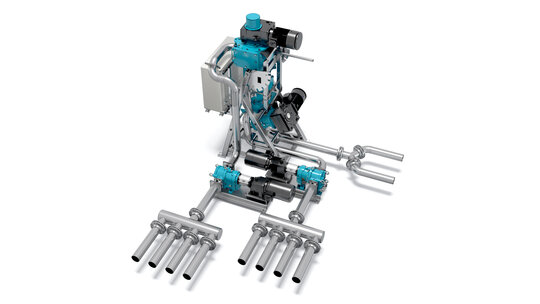

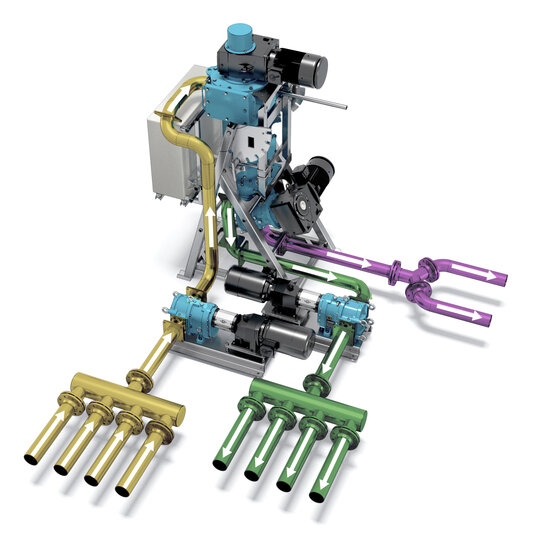

The Bioselect BS can be used to supply complex systems. The medium is supplied from the requested tank to the Bioselect through the manifold (A).

The liquid phase pump (B) transports the liquid phase to its destination. The thickened phase which can still be pumped is conveyed by the thick matter pump (C) for further use.

MIP® = Maintenance in Place

Simple and uncomplicated

The Bioselect BS is maintained at its installation site.

The control cabinet is simply swung to the side and the Bioselect is moved from the working into its maintenance position. In the maintenance position, a space-saving replacement of all wear parts is easily possible.

The operator themselves can maintain the Bioselect. Easy, cost-effective and quick.

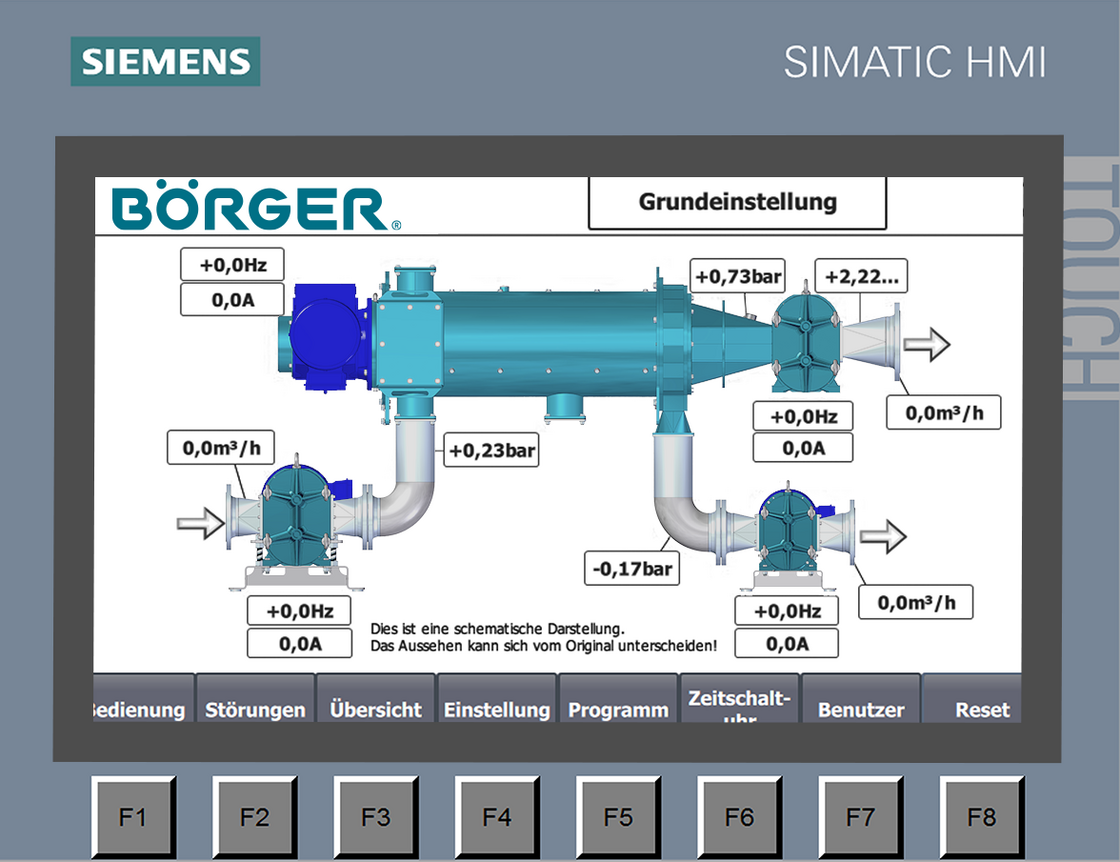

- Ideal coordination of the operation of all components (e.g. feed pump, macerator, liquid phase pump, Bioselect)

- Perfect utilization of the Bioselect, even with changing composition of the medium being fed, by a control that ensures optimal loading (metered feeding)

- Control of pneumatic valves, conveyor belt, macerating technology

- Production data acquisition (operating hours, flow rate, etc.)

- Protection of the entire system (pressure monitoring, dry run protection, function monitoring, etc.)

- Integration via bus system (Profinet, Profibus, etc.)

- Simple entry and user administration via touch display

- External control by operator possible via mobile communication, WLAN, DSL (remote maintenance by Börger is also possible)

- and so on

Quality from a single source

- Compact device ready for installation: Simply connect power lines and piping and start operation

- "Everything from a single source“: We guarantee perfectly matched components for optimum operation.

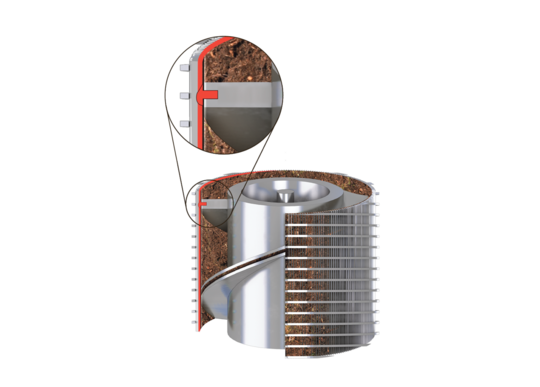

- Water extraction and press channels are separated to protect material: This special design preserves the screening area.

Thickened raw liquid manure for the biogas plant

The operator of a biogas plant uses the Bioselect BS to thicken raw liquid manure before feeding it into the biogas plant.

A pump conveys the raw liquid manure into the Bioselect BS. The Bioselect BS thickens this material.

The thickened phase is very rich in energy. It is conveyed into the fermenter by a pump. The liquid phase is transported into a storage tank for further use.

Thickening of recirculate

A biogas plant in Westphalia, Germany uses the Bioselect BS to extract liquid from the fermenter.

A pump conveys recirculate from the fermenter into the Bioselect BS. The BS thickens the material and either conveys the solid phase, e.g. with a DS content of 15 %, back into the fermenter or into the secondary fermenter.

The liquid phase is transported into final storage or to further processing.