Biogas

Separating plastic particles from digestate

A British biogas plant feeds its fermenter with corn and food waste. The food waste contains small portions of packaging remains. According to regulations, in Great Britain, all plastic particles larger than 12 mm (0.47 inch) must be removed from the biomass after the fermentation process. To this end, the biogas plant uses a Bioselect RC.

The powerful separator is installed on a mobile base frame together with a rotary lobe feed pump, a liquid phase pump and the control technology. The entire system is very easy to operate via a touch display. The food waste and the biomass are strongly decomposed during the fermentation process, so that a sufficiently fluid material is produced. The Bioselect separates all plastic particles larger than 1 mm (0.04 inch) while reaching a high dewatering degree.

The liquid phase is spread on meadows and fields. Since it contains virtually no solids anymore, it runs off grasses and leaves very easily and quickly seeps into the soil.

Biogas

Renewable resources - biogas substrate

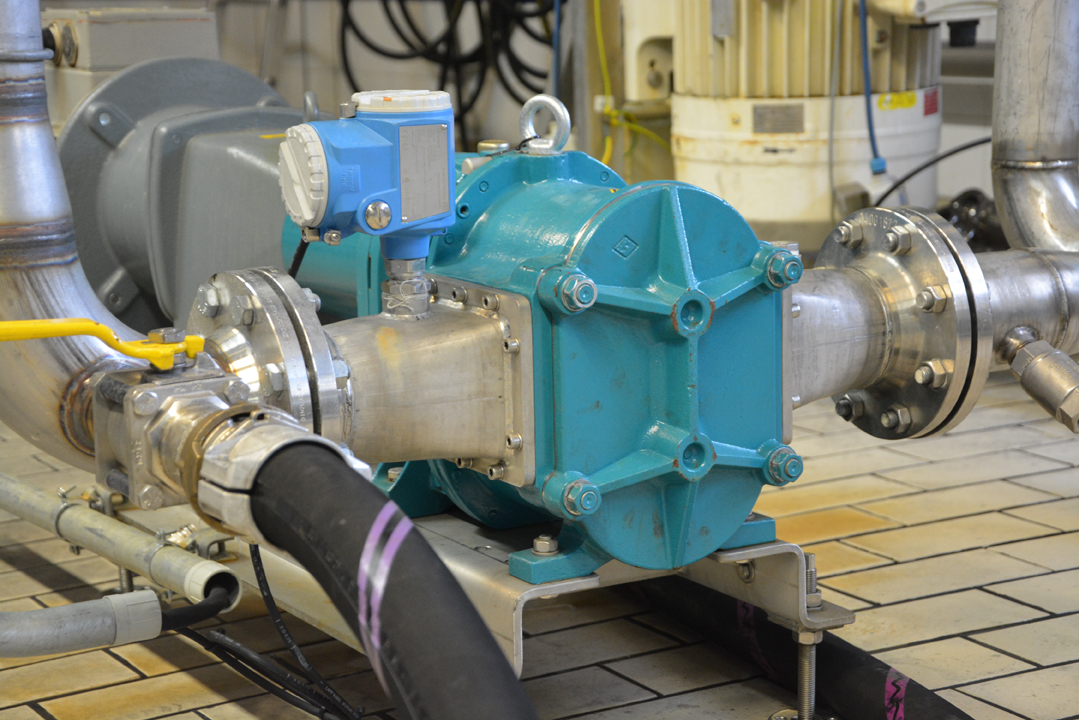

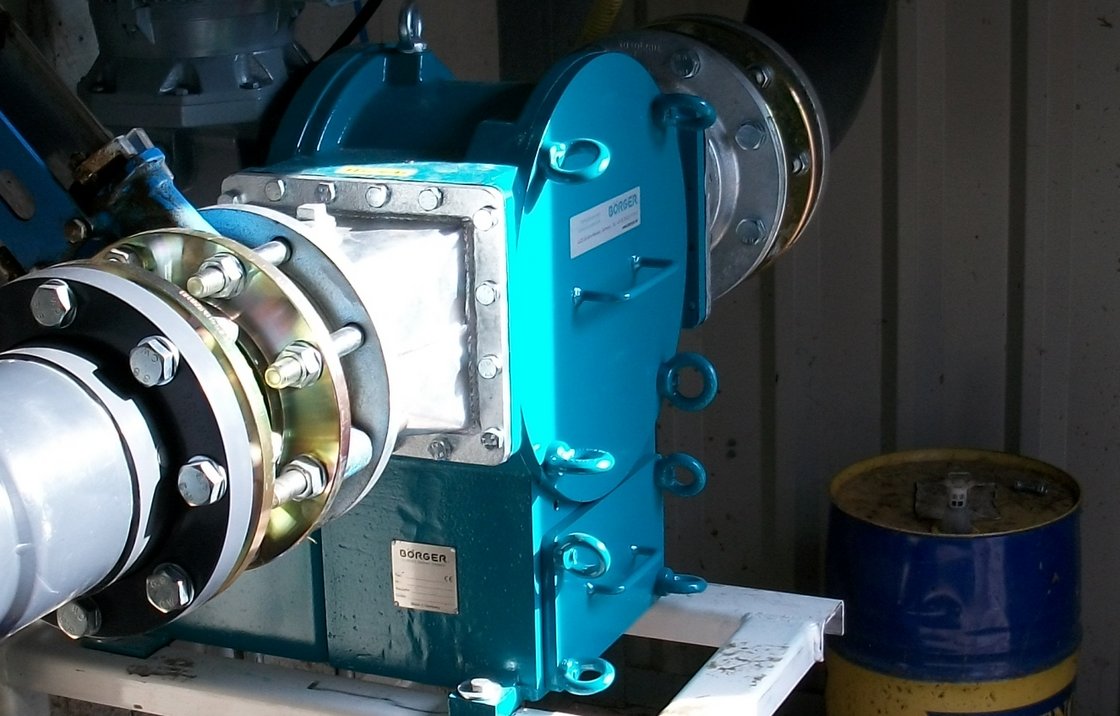

The operator of a biogas plant was looking for a reliable pump for transferring highly abrasive biogas substrate from a fermenter to a secondary fermenter. The rotary lobe pump previously used increasingly suffered from extreme wear on the rotor. It was essential for the operator of the biogas plant to have a pump on-site with a long service life and low wear that is easy to maintain in the case of repairs. Owing to the design of the pipeline system, the pump had to be able to cope with pressure of -0.4 bar (-5.8 psi).

The customer decided on a Börger Rotary Lobe Pump. The speed of the Börger pump is controlled by a frequency converter depending on the negative pressure. An electronic pressure gauge measures the pressure.

Biogas

Biogas plant

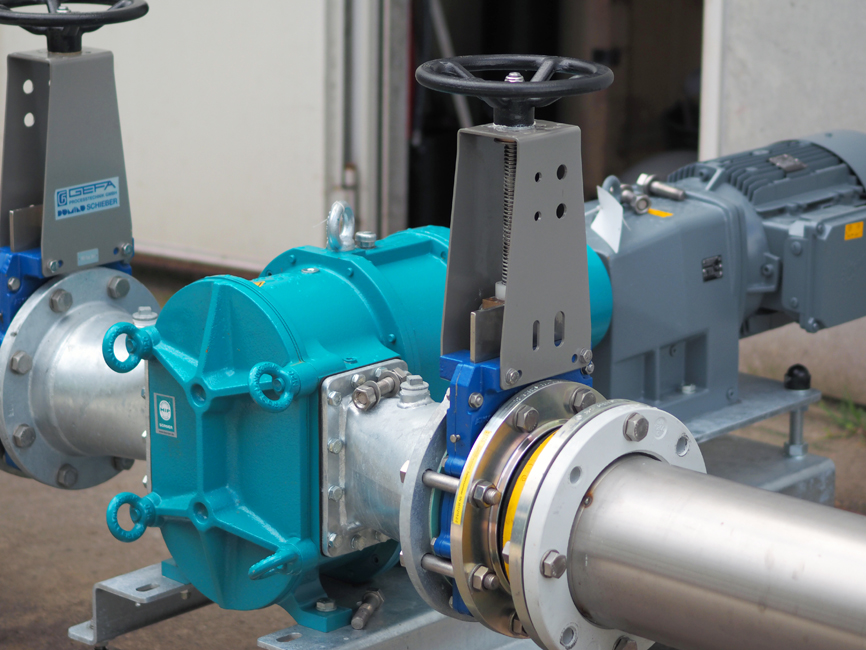

The operator of a biogas plant was not satisfied with the rotary lobe pumps in use made by a competitor. The pumps showed signs of severe wear on the rotors after just a few weeks. There were also frequent occurrences of damage to the seals and gears. The operator of the biogas plant conducted a yearlong test to find the optimum pump for his requirements. Several pumps were tested. At the end of the test phase, the customer appointed 40 Börger Rotary Lobe Pumps to be installed in the biogas plant.

The impeccable quality and low maintenance design of the Börger Rotary Lobe Pump impressed the customer, particularly the Börger Premium profile rotors, which were especially developed for the biogas sector. Fibrous matter in renewable resources is captured in the profile grooves of the Premium profile rotor. This constantly exchanging film forms all over the seal between the rotors and the casing. Besides the high level of pump efficiency, this patented technology enables premium profile rotor operation be virtually free of wear.

Biogas

Silages

At a two-stage biogas plant, staff were having increasing problems with blockages in an eccentric screw pump due to solids. The pump was installed between the main and secondary fermenter. Various silages are used within the plant (corn, millet, grass, rye) as well as dried chicken manure.

The customer chose a Börger Rotorrake to reduce the solids. The Rotorrake was fitted on the suction side directly in front of the eccentric screw pump.

The operator of the biogas plant is extremely pleased with the chopping yield. No more pump blockages occurred. The Börger Rotorrake's long service life and ease of maintenance continue to impress the customer. He is now considering using additional Börger products for the biogas plant.

Biogas

Solids feeding

An agricultural holding was looking for reliable feeding technology for transferring corn silage to a biogas plant.

After scrutinizing the feeding technology of various providers, the biogas plant operator chose the Börger Powerfeed 400. The customer was impressed with the renowned high quality of the Börger products, particularly the entirely closed system, the uncomplicated, easy controls and the Powerfeed design which prevents gas from escaping.

The customer chose a Börger Biogas Rotary Lobe Pump to convey the recirculate.

The customer is extremely pleased with the Börger Biogas Rotary Lobe Pump and the Powerfeed 400. The long service life and easy handling ensure efficient operation of the biogas plant.

Biogas

Solids supply

A plant construction company specializing in optimizing biogas plants was looking for feeding technology for a 950 kW plant. It was essential that the technology would be odorless and free of gas.

The plant construction company opted for a Börger Powerfeed. They were impressed with the Powerfeed's innovative and sophisticated technology and particularly with the high efficiency of Börger feeding technology. The renewable resources are worn down due to the positioning and type of the press unit in the Powerfeed as well as the design of blade and dosing unit. Through this they obtain a larger surface area. All the trapped air is released by compressing the solids into clumps. Less floating layers form in the tank.

By specifically dosing the solids, the agitating in the tank could be significantly reduced. The plant construction company and the plant operator are extremely satisfied with the Börger Powerfeed.

Biogas

Separation

The operator of a biogas plant was looking for an effective separator. The plant operator had noticed that the solids content in the fermenter and the secondary fermenter was too high. Therefore, a separator was required to remove the solids from the substrate.

The customer opted for a Börger Bioselect RC 40, as he had used Börger products with excellent results and had heard about the simple but highly efficient operation of the Bioselect. A Börger PL 200 Rotary Lobe Pump conveyed the substrate from the fermenter to the Bioselect. A control unit continuously regulates the Bioselect's optimum load. The Bioselect separates the solids from the liquid phase. The solids leave the system, while the liquid phase is fed back into the fermenter in parts.

The customer is highly satisfied with the reliable Börger Bioselect. The easy handling and loose consistency of the solids were key factors in the decision.

Biogas

Separation of solids and liquid

The operator of a biogas plant was looking for a compact separation unit which could be mounted on a trailer. A top priority for the operator was that the separator should be easy to operate.

The customer decided on a Börger Bioselect BS. The Bioselect BS is a highly efficient combination of two Börger Rotary Lobe Pumps and effective filter technology with a downstream press channel.One of the rotary lobe pumps ensures that the thick mass is reliably sealed and at the same time transfers it for further processing. Using an intelligent control unit and the adjustable pump speed, the degree of thickness can be determined.

The Bioselect is mounted on a trailer, as the plant operator wanted to use the unit in various locations. The customer wanted to reduce the DS content in the biogas plant fermenters. To achieve this, the solids are separated from the secondary fermenter by the Bioselect. The thin phase is pumped in the closed system to the fermenter or the final storage tank. The different substances (thin and thick phase) are conveyed for further processing with the separator pumps. Additional pumps are not required. The Bioselect operates in continuous mode for 12 hours per day. The customer is extremely pleased with the Bioselect BS, particularly with the reliable operation and easy handling of the separator.

Biogas

Fermenter

The operator of a biogas plant was looking for three new tanks for the facility. They were to be used as a beet store, a fermenter and final storage tank. The tank for final storage needed to have a volume of 5,000 m³ (1,320,860 gal).

The customer opted for three Börger stainless steel tanks. The customer was particularly impressed with all the options available for Börger stainless steel tanks. The customer could select the perfect solution for his requirements from the wide range of different covers. The plan is to extend the beet tank from the current storage capacity of 1,895 m³ (500,606 gal) up to 2,527 m³ (667,563 gal) in 2015.

The stability of the stainless steel tank and the option of dismantling it to assemble in another location gave the operator of the biogas plant financial security should the guaranteed payments for power feed into the power under the terms of the German Renewable Energy Act end after 20 years.

Biogas

Powerfeed duo

A biogas plant operator was looking for reliable liquid feeding technology to feed solids into their secondary fermenter. The biogas plant was upgraded to include an additional CHP. The feeding technology was also required to load the fermenter and replace the plug screw currently used.

After finding out about state-of-the-art technology from various manufacturers, the biogas plant operator decided on Börger's Powerfeed duo. In addition to the renowned optimum reliability of Börger products, the customer was also particularly impressed by the Powerfeed duo's well-engineered, integrated design concept.

The storage tank supplied with the Powerfeed duo can be filled directly using a wheeled loader. Constant loading of the Powerfeed is guaranteed thanks to the 10 t storage capacity.

The Powerfeed and a high-capacity biogas pump form the central unit of the liquid feeding technology. The unit is very easy to operate using an operating device at the control cabinet. A control unit ensures trouble-free system operation. Different sensors constantly monitor the fill level in the Powerfeed. The data readings are transmitted to the control unit. The Powerfeed switches off automatically when the pre-set limits are exceeded.

The customer is very satisfied with the Powerfeed duo. He was won over by its optimum reliability, easy operation and efficient biomass feed.

Biogas

Powerfeed connect

An operator of a biogas plant has been using a solids dosing feeder for feeding the biomass into the fermenter for several years. The operator was looking for an alternative feeding technology due to the extension of the biogas plant and the very high agitating effort.

The operator opted for a Börger Powerfeed connect. The liquid feeding technology can be used for feeding tanks of any number. In addition, they were able to use the existing technology to a large extent.

The biogas plant operator is very satisfied with the Powerfeed connect. The customer was particularly impressed by the ease of operation, the trouble-free operation and the long service life. In addition, the agitating effort in the tanks has been significantly reduced and the gas yield has been increased.

Biogas

Separating plastic particles from digestate

A British biogas plant feeds its fermenter with corn and food waste. The food waste contains small portions of packaging remains. According to regulations, in Great Britain, all plastic particles larger than 12 mm (0.47 inch) must be removed from the biomass after the fermentation process. To this end, the biogas plant uses a Bioselect RC.

The powerful separator is installed on a mobile base frame together with a rotary lobe feed pump, a liquid phase pump and the control technology. The entire system is very easy to operate via a touch display. The food waste and the biomass are strongly decomposed during the fermentation process, so that a sufficiently fluid material is produced. The Bioselect separates all plastic particles larger than 1 mm (0.04 inch) while reaching a high dewatering degree.

The liquid phase is spread on meadows and fields. Since it contains virtually no solids anymore, it runs off grasses and leaves very easily and quickly seeps into the soil.