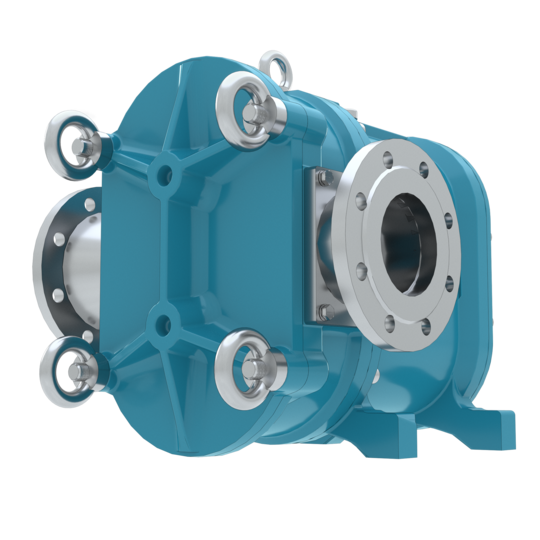

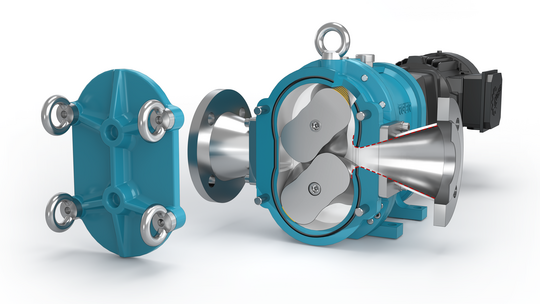

The perfect symbiosis: rotors and casing

Made for one another

The development of the BLUEline Nova pump has benefited from our experience of more than 30 years in pump manufacturing. With the help of computer flow simulations and physical test bench hours, we were able to improve the pumps even further.

To this end, the geometries of the pump chamber and the rotors were perfectly matched. The result: The best volumetric efficiency that has ever been achieved combined with perfectly smooth running even at high pressures.

For pure media - BLUEline Nova clean

The “clean” version of the BLUEline Nova has been designed for conveying pure, non-abrasive media. Casing protection is not required.

The pump with minimum dead space can be cleaned according to the hygiene procedures CIP (Cleaning-In-Place) and SIP (Sterilization-In-Place).

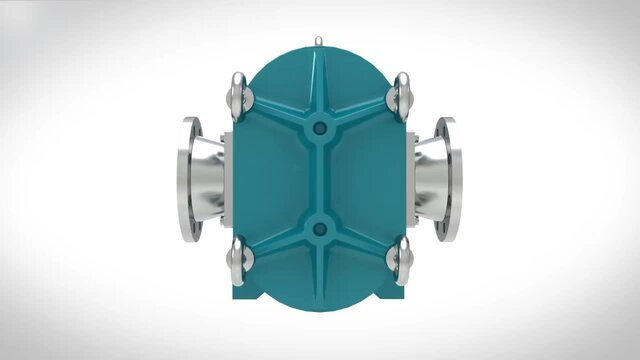

For abrasive media - BLUEline Nova tough

For conveying abrasive media containing solids, we have developed the Nova tough. A radial and axial casing protection protects the entire pump casing.

The protection plates and liners are perfectly integrated into the pump casing in a flow-optimized design. In case of wear, the casing protection is replaced quickly and easily thanks to the MIP® design (Maintenance in Place).

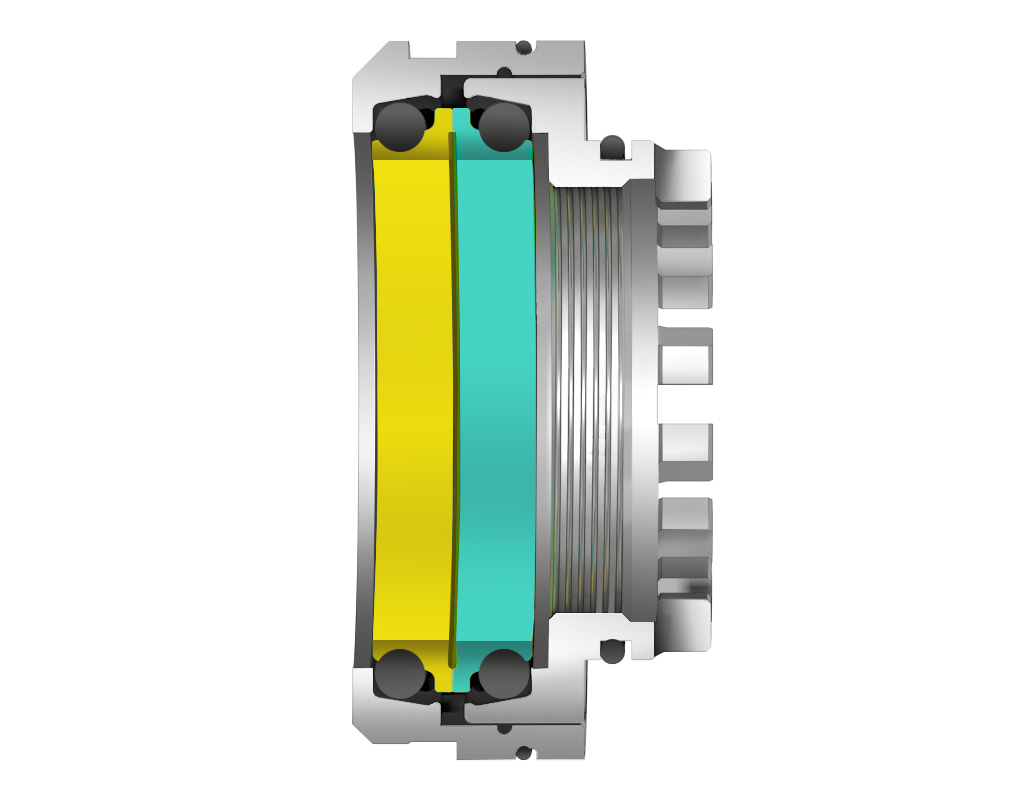

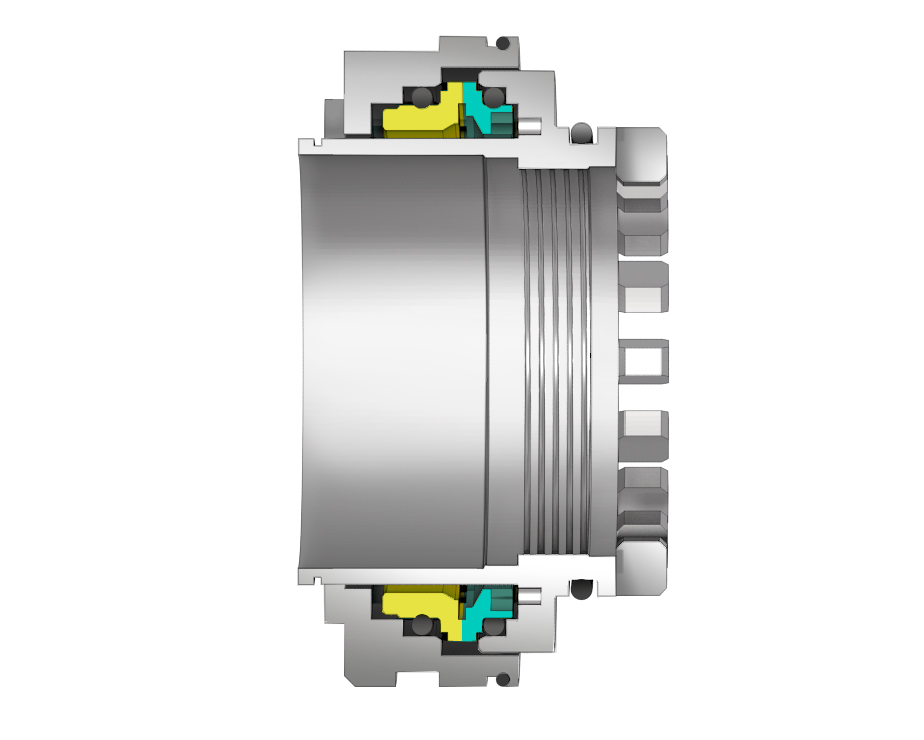

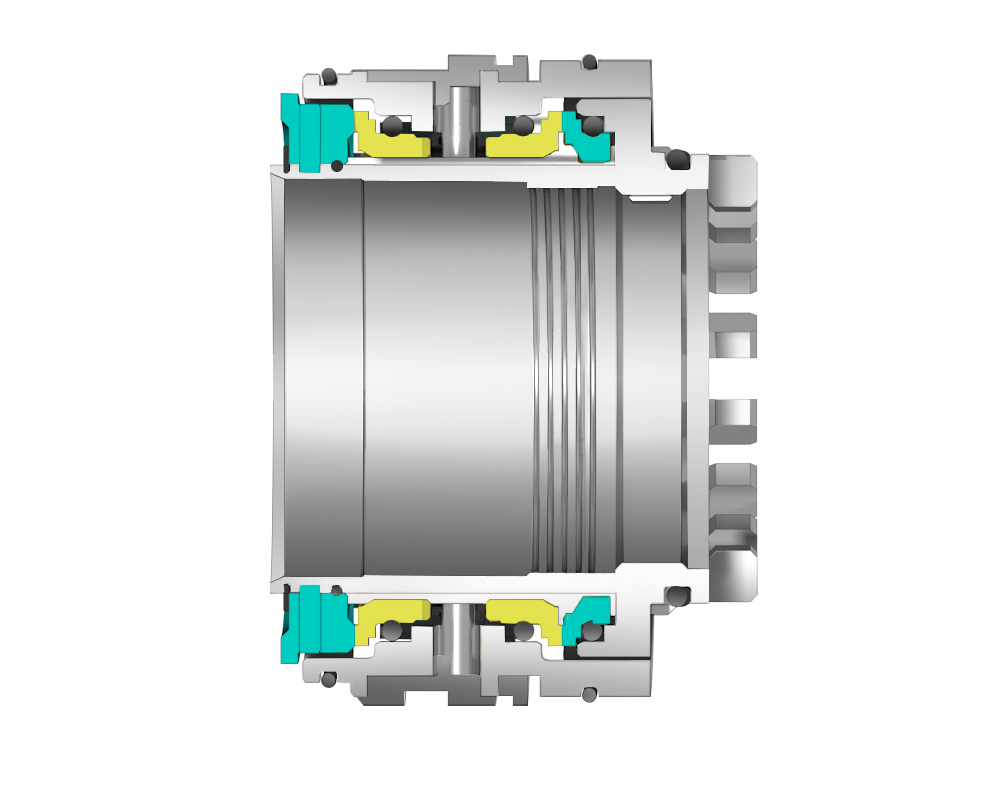

Mechanical seals

A lot of space for a lot of seal

The BLUEline Nova has a very large seal chamber and provides space for almost any sealing system. This way, there is always a sealing system which is perfectly suited to the pumped medium. Connections for circulation lines are integrated in the pump casing.

Börger offers different types of seals which are selected for the specific applications.

BLUEline series Pump size | Min. Speed in rpm | Max. Speed in rpm | Min. in m3/hFlow rate | Max. in m3/hFlow rate | Max. Pressure in bar | Max. Temp. in °C | ||

|---|---|---|---|---|---|---|---|---|

| AN | AN 040 AN 070 | 1 1 | 800 800 | 0.03 0.04 | 20 35 | 10 8 | 200 200 | AN 040 AN 070 |

| PN | PN 100 PN 160 | 1 1 | 800 800 | 0.06 0.10 | 50 75 | 12 12 | 200 200 | PN 100 PN 160 |

| QN | QN 230 QN 300 | 1 1 | 600 600 | 0.14 0.18 | 85 110 | 8 8 | 200 200 | QN 230 QN 300 |

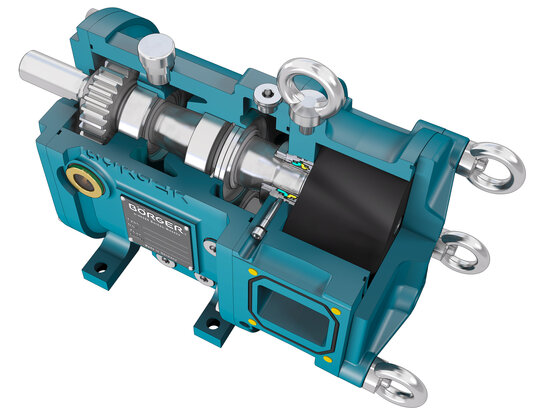

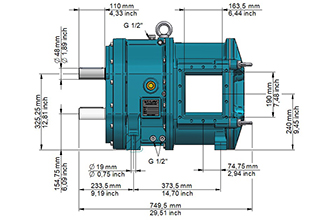

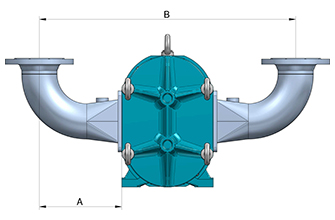

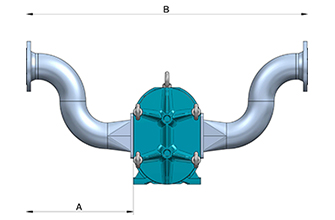

Compact design

With directly flanged drive

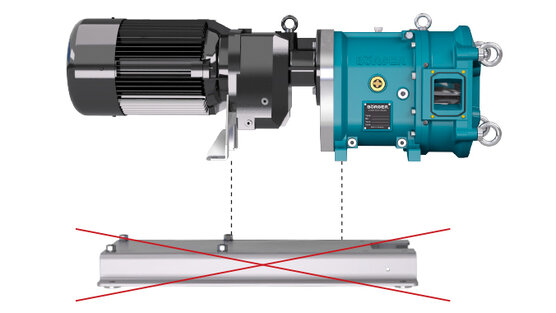

The BLUEline Nova can be used with different drives. Upon request, the drive is directly flanged to the pump. Due to the elimination of the coupling and the base frame, the unit is even more compact.

- An additional coupling is not required

- Short design

- Simple integration into complex systems

- Low-on-space design

- Weight reduction by elimination of the base frame

Water glass (sodium silicate)

A manufacturer of moldings for cupola and shaft furnaces uses Börger BLUEline Nova rotary lobe pumps to convey water glass in its production plant. The water glass serves as a binder for the pulverized coal of a new type of briquette.

Pump 1 conveys the water glass from a storage tank into an intermediate container. Pump 2 is used to feed the mixer below via nozzles. Water glass places high demands on the mechanical seal because it hardens very quickly on contact with air. For this reason, the stainless steel pumps are equipped with double-acting mechanical seals. The seals are pressurized by means of a barrier pressure supply system.

Suspensions

A chemical company has specialized in the production of additives for the food industry, cleaning agents, paints, and lacquers. The company uses a BLUEline Nova hand cart pump for conveying different suspensions with viscosities between 100 and 80,000 mPas.

The fluids to be pumped have temperatures between 20 and 95 °C (68 - 203 °F). In order to adjust the speed and, as a result, the flow rate to the properties of the different fluids, the pump is operated via a frequency converter.

Due to the abrasive components in the pumped media, the “tough” version of the stainless steel pump is equipped with stainless steel casing protection plates and liners. In case of wear, the casing protection can simply be replaced. A Variocap protects the pump from uncontrolled pressure surges.

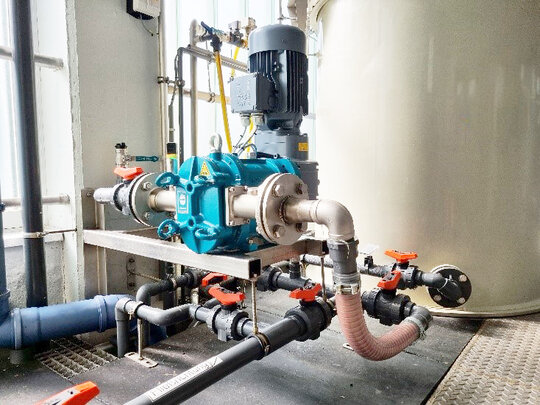

Elastomers

The operator of a wastewater treatment plant in Austria uses a BLUEline Nova clean for conveying elastomers.

The “clean” version of the Nova pump has no casing protection, so that there are hardly any dead spaces. The pump is driven by a directly mounted helical bevel geared motor, which makes it even more compact.

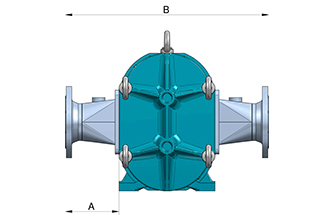

Reject water

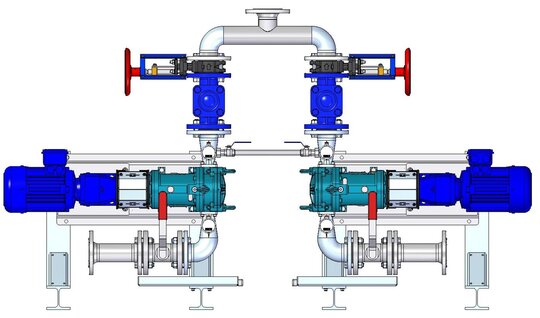

One of the largest shipbuilding companies in the world uses BLUEline Nova pumps for conveying reject water on their ships. In addition to the high flow rate with a very compact design, the high volumetric efficiency of the new pumps is a crucial factor for the customer.

The casing plates and liners protect the pumps against solids in the medium and are perfectly integrated into the pump casing in a flow-optimized design. Thanks to the innovative fastening system, the Nova pumps ensure excellent efficiency also with casing plates and liners installed. The two Nova pumps are installed turned 90°. Considering the limited space available on board the ships, this reduces space requirements even further.