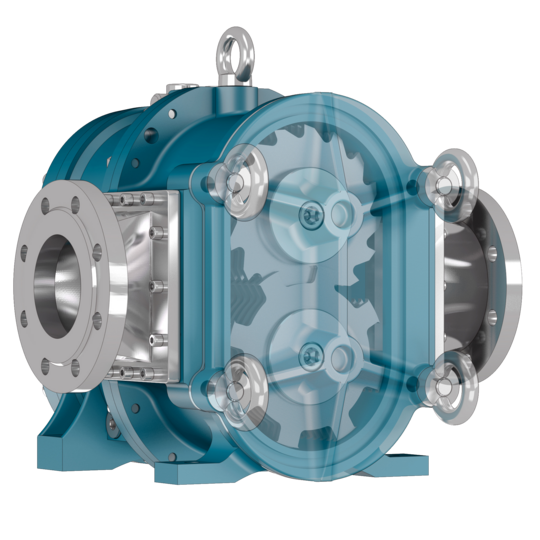

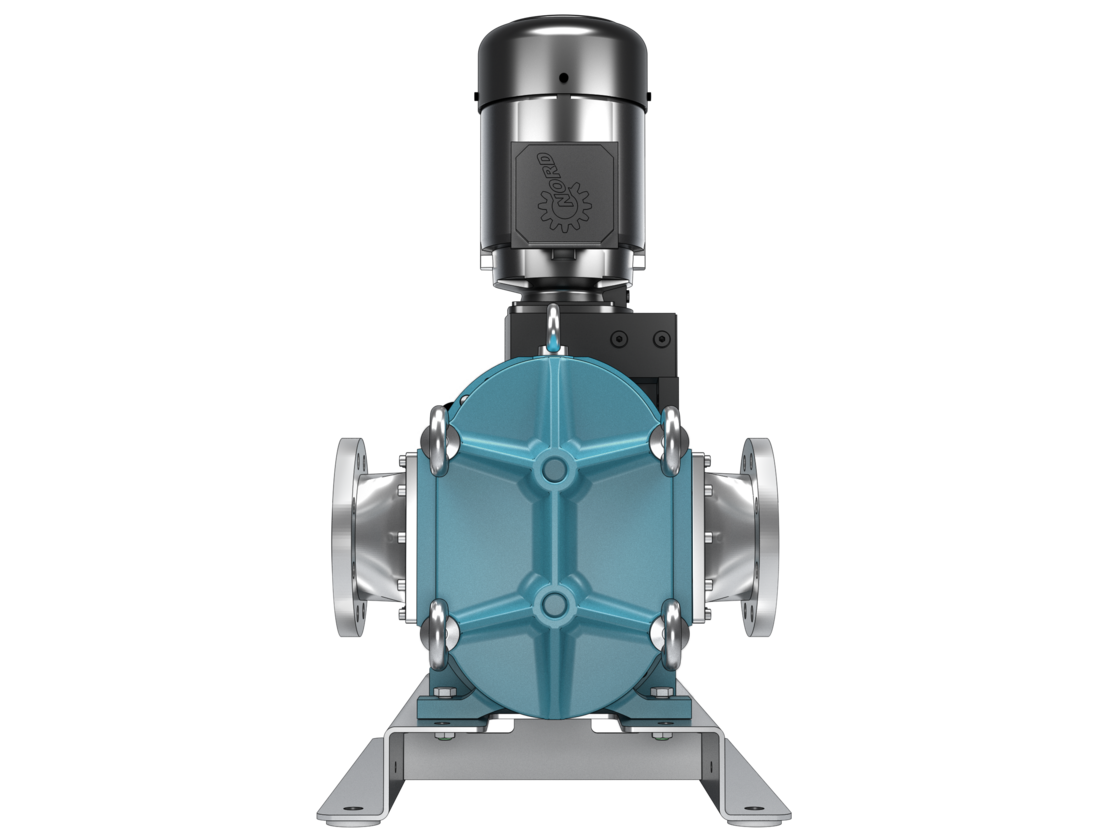

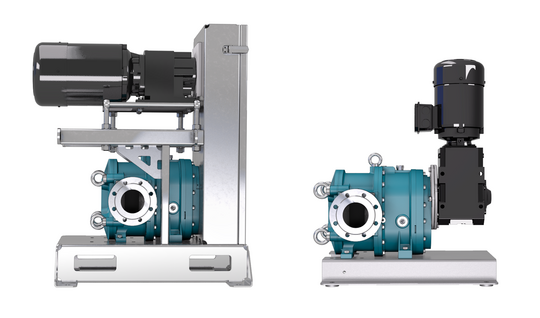

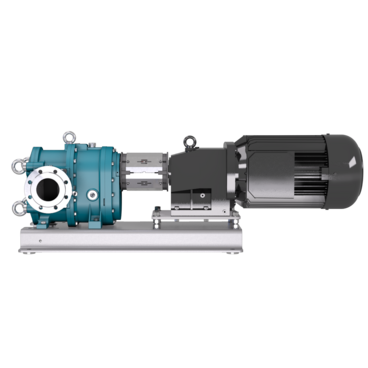

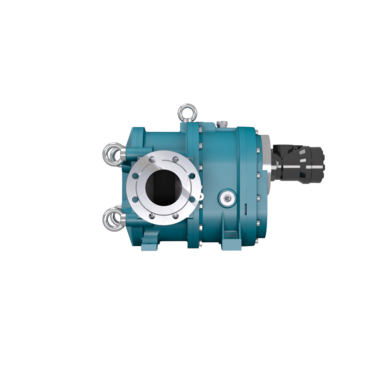

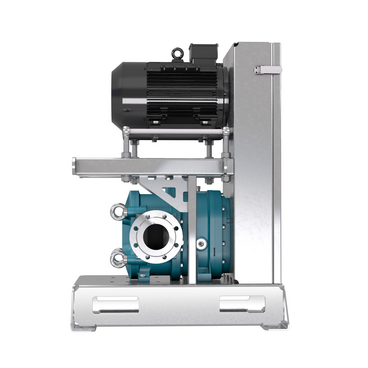

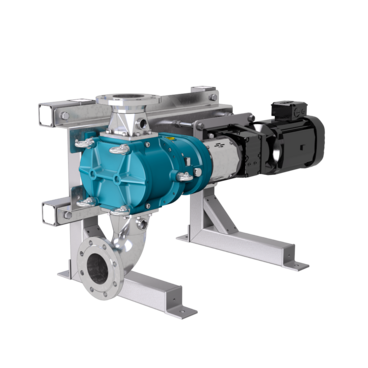

The Multicrusher protects pumps and piping systems from damage or blockages caused by solids. The compact two-shaft macerator is simply installed in the pipeline upstream of the pump.

The Multicrusher macerates the solids efficiently and protects the unit. In addition, the Multicrusher homogenizes the medium, thereby facilitating the pumping process.

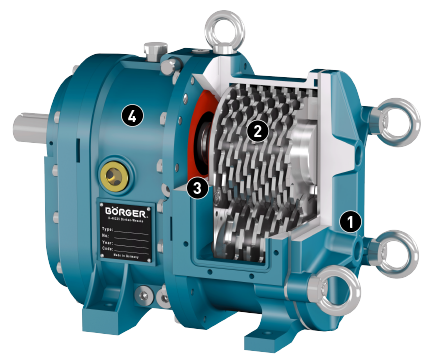

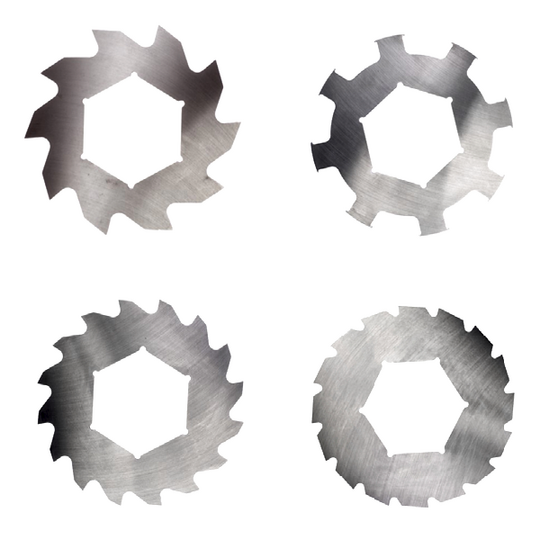

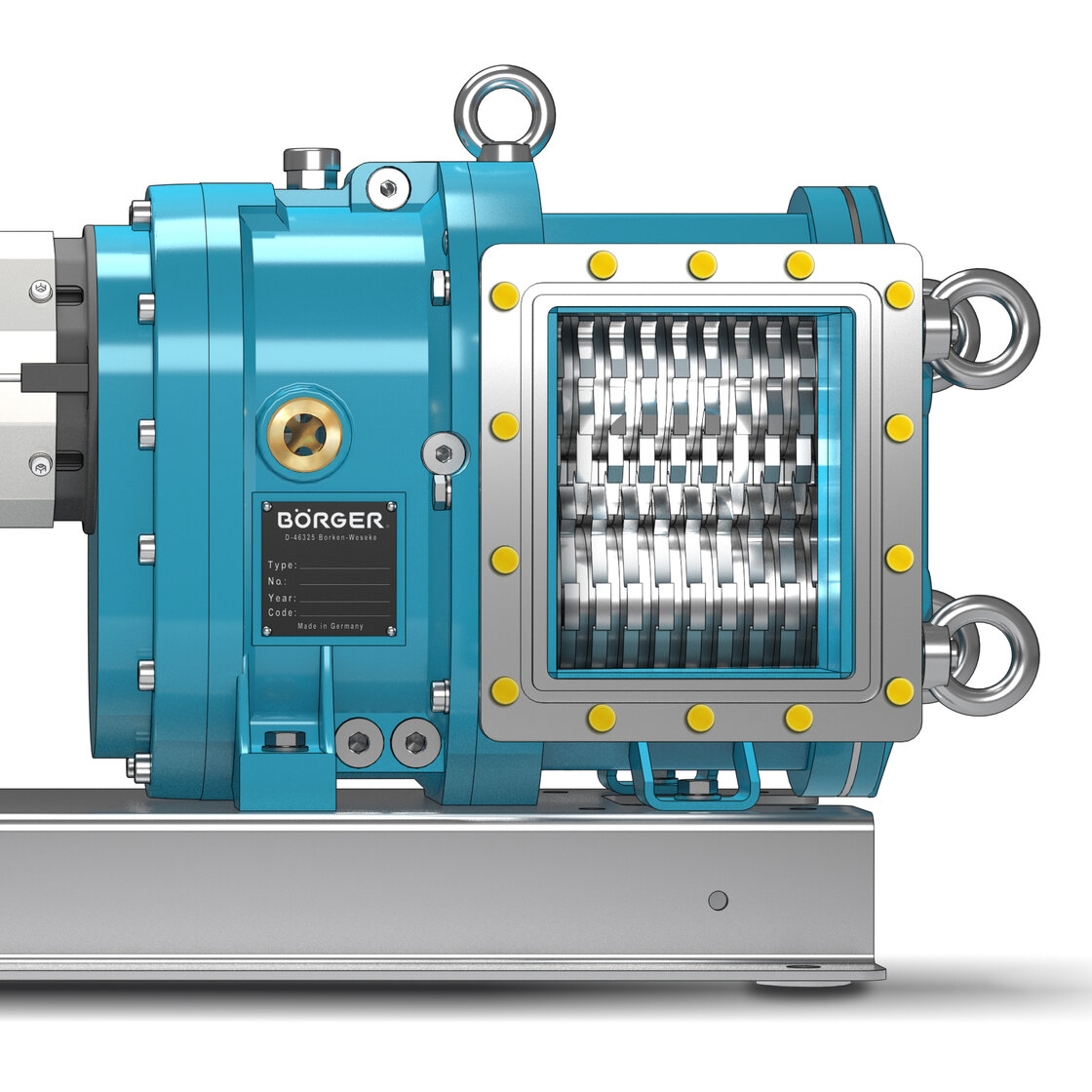

Rotating blade disks shred the solids

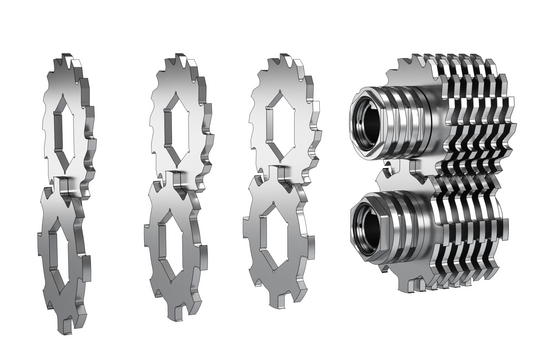

The dual-shaft grinder was designed using the principle of the Börger rotary lobe pump.

Meshing cutting blades rotate on the two shafts of the Multicrusher. The solids pass through the counter-rotating blade configuration and the solids are macerated in the process.

The different circumferential speeds and blade configurations ensure excellent cutting results.

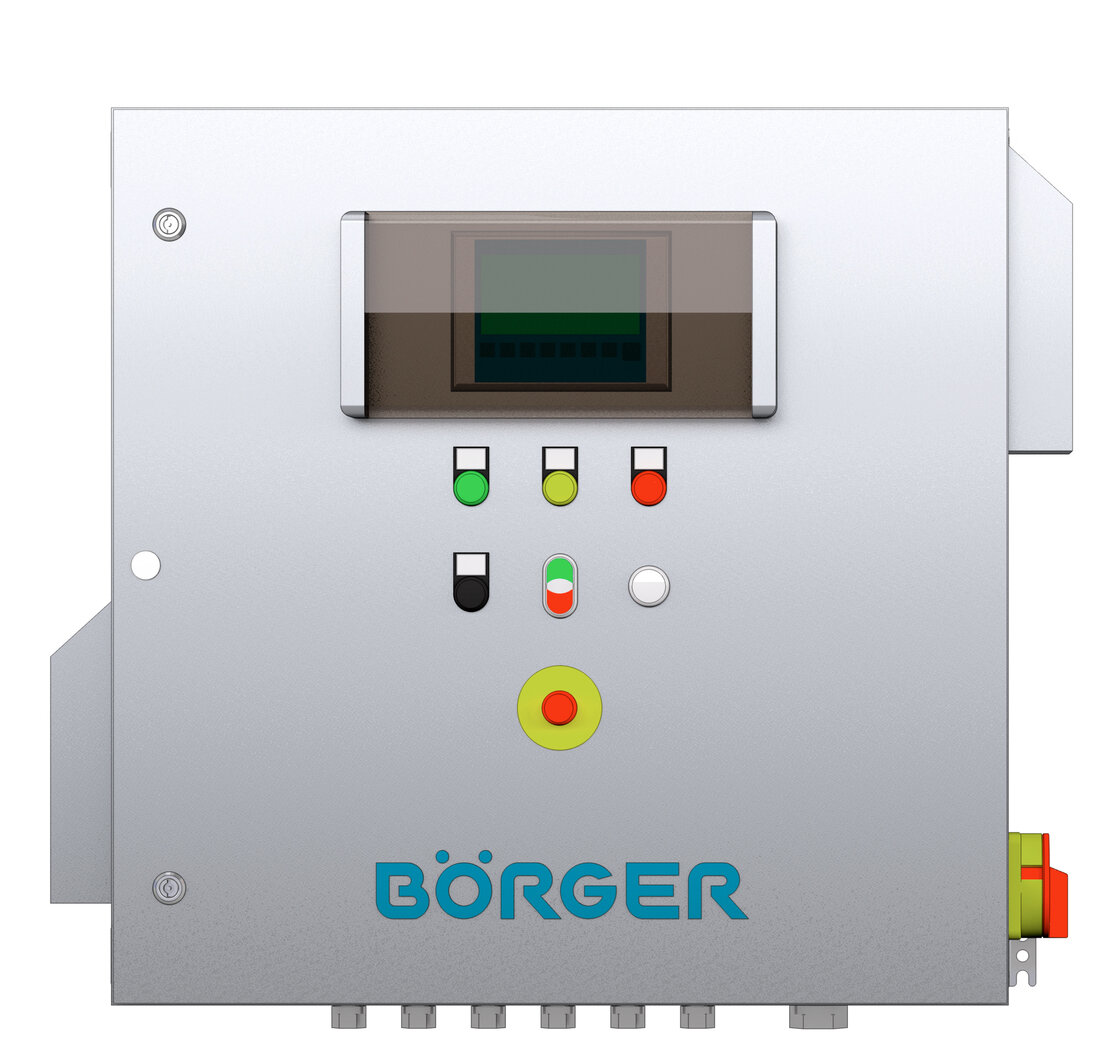

- Highest degree of operational safety due to reversing control (load- and/or time-dependent reversing)

- Easily adjustable reversing parameters

- External control by operator possible via smartphone, WLAN, DSL (remote maintenance by Börger is also possible)

- Production data acquisition

- Simple entry and user administration via touch display

- Module or control cabinet solutions

- Integration via bus system (Profinet, Profibus, etc.)

- and so on

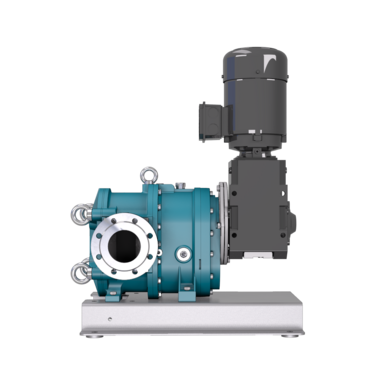

MIP® = Maintenance in Place

Uniquely easy to maintain

Working hours shouldn't be wasted on maintenance.

In case of wear, all wear parts can simply be replaced through the quick-release cover. The Multicrusher does not have to be removed. Just open the quick-release cover and carry out the maintenance work within a few minutes on site.

An overhead crane is not required.

Extra large inlet and outlet openings

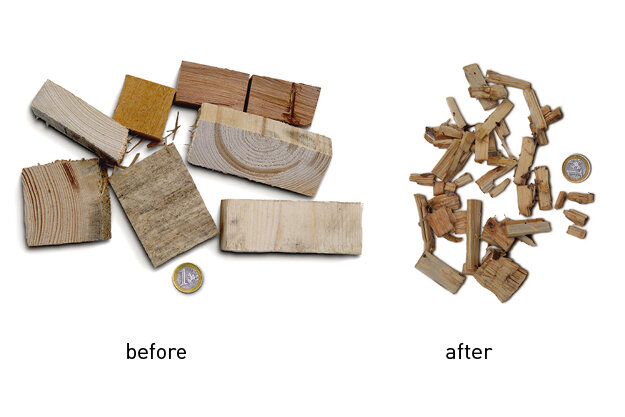

The Multicusher is available with extra large inlet and outlet openings. This makes it possible to shred also very coarse solids without any problems.

In the liquid flow, the solids are directed to the cutting surfaces of the blade blocks. The sharp blade edges capture the solids and break them down into tiny particles with little energy input.

ATEX-compliant? No problem.

The ATEX Directive 94/9/EC defines the prescribed technical requirements for equipment and protective systems intended for use in potentially explosive atmospheres in Europe. All Börger Multicrushers can be used in potentially explosive atmospheres in accordance with the ATEX Directive.

Air Pollution Control Act

The technical guideline for air quality control is the German government's “first general administrative regulation under the federal Air Pollution Control Act”.

The Multicrusher can be built to be used for lawfully handling toxic and highly toxic media in accordance with the Air Pollution Control Act.

Case Studies

Practical example

The Multicrusher is very versatile. Thanks to its space-saving design, outstanding macerating performance and die large number of options for a customized adjustment, it is the best solution for many macerating tasks.

The industries and applications listed here give you an impression of the versatile application options of Börger Multicrushers.

Raw sludge

In a municipal wastewater treatment plant in Sweden a pump conveys the raw sludge from the thickener to a digestion tank. Inside the pipes, valves and the pump, repeated blockages occurred caused by rags, toiletries and entanglements. A Multicrusher was installed in the pipeline upstream of the pump to macerate the solids.

There have been no blockages ever since. The customer is surprised about the low noise level. In addition, the Multicrusher does not have to be removed from the pipeline during maintenance. If any damage on one of the blades is noted during the maintenance work performed at regular intervals, it is not necessary to replace the entire blade block. The operator can replace the damaged blade only. Despite the demanding application, the Multicrusher has been operating since 2014 with just one blade change.

Thin sludge

This Multicrusher is installed upstream of a decanter. It shreds the solids in the thin sludge and separates impurities. Before the thin sludge containing solids is sucked through the Multicrusher, it has to pass through the debris collector.

Here, solids that cannot be macerated, such as large stones, glass, or metal objects, are separated. Inside the Multicrusher, the rotating blades shred the solids and homogenize the thin sludge before it enters the decanter.

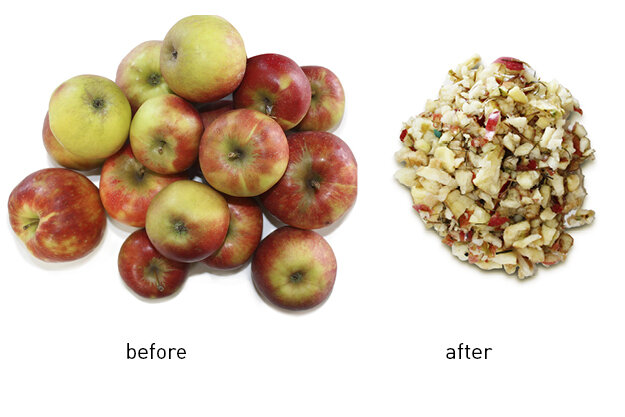

Food waste

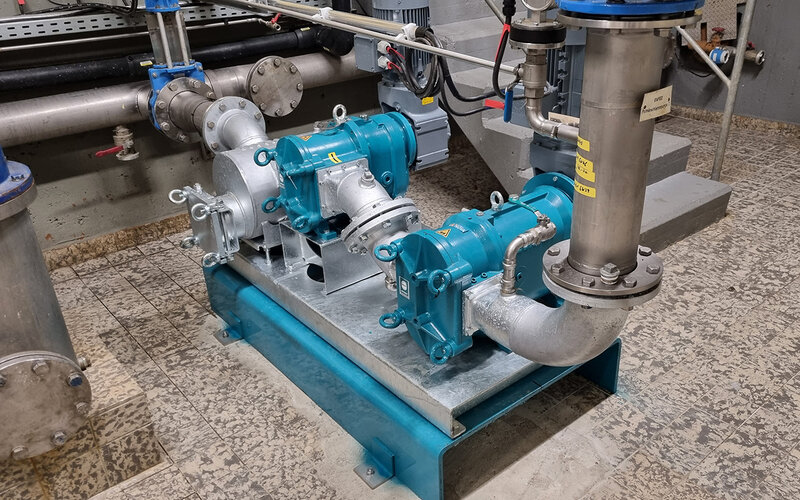

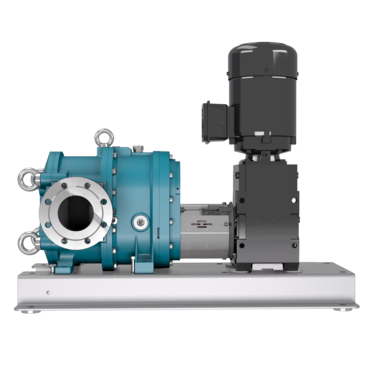

A space-saving combination of a Börger Rotary Lobe Pump and a Multicrusher is used on a cruise ship to convey and macerate food waste.

Despite the confined space on board, all maintenance work can be done at the installation sites of the pump and the macerator without removing them. The customer especially liked the option to replace individual blades instead of the entire blade block of the macerator during maintenance. A debris collector is installed upstream of the Multicrusher. Here, objects that cannot be shredded, such as cutlery or bones, are collected.

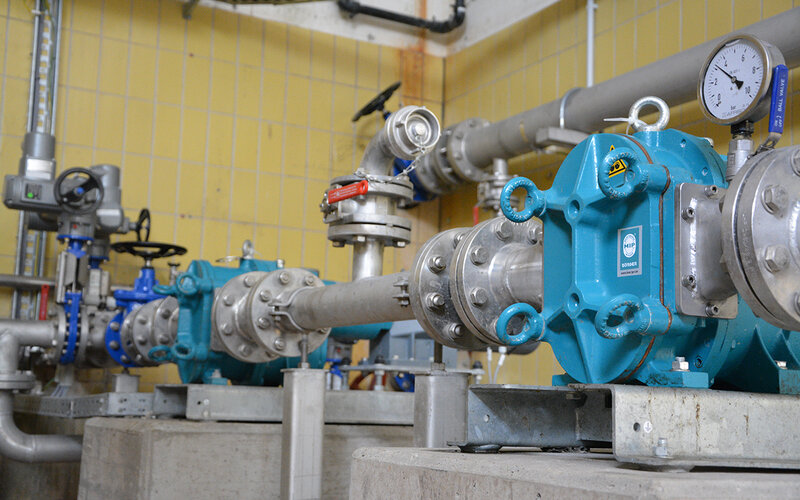

Liquid waste

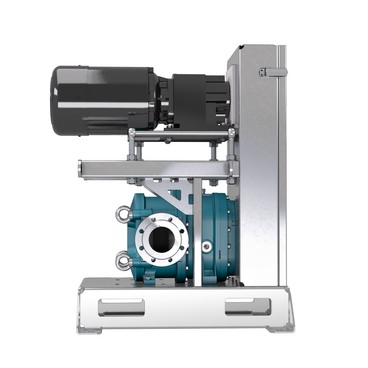

A disposal company uses Multicrushers for the maceration of solids in secondary fuels. Tanker trucks deliver the liquid waste from different industrial companies to the incineration plant. The waste is mainly used solvents, used acids and used lyes. At the receiving points, the products are sampled before being removed from the tanker trucks and then conveyed into the product-specific tanks. Multicrushers are installed upstream of the pumps.

They shred the solids contained in the delivered fluids effectively and reliably. This prevents blocking and damage to the pumps and pipelines. The Multicrushers have an ATEX-compliant design and are permanently technically tight pursuant to TA Luft for use in potentially explosive atmospheres. In order to save space, the Multicrushers are driven by vertically installed motors.

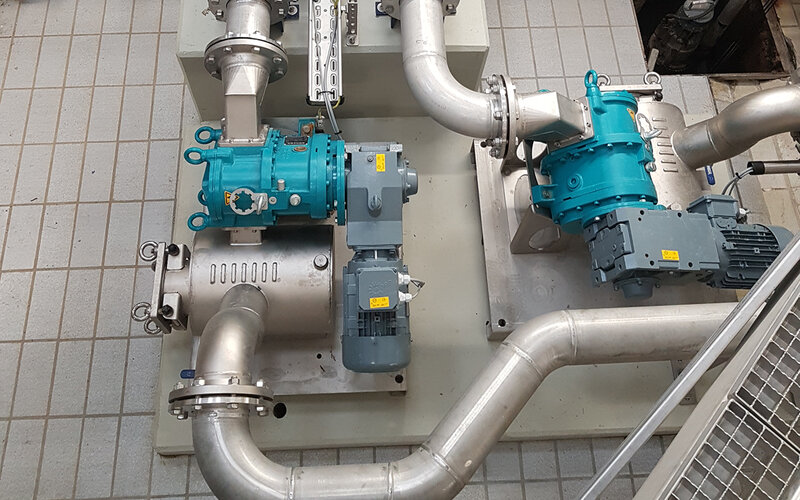

Primary sludge

The dry substance content had increased due to a certain process at a wastewater treatment plant. Since then, faults had occurred at several points in the pump due to solids accumulating and blocking the pumps. The blockages were causing frequent damage.

After successfully conducting different tests, they opted for the Börger Multicrusher for dealing with the primary sludge. The Multicrusher was installed on the suction side of the two primary sludge pumps which transfer the sludge alternately.

Operating safety, chopping performance and the reasonable wear parts were decisive in convincing the wastewater treatment operator. Since the Multicrusher was installed, the primary sludge pumps have been running smoothly.