Construction chemistry, paints, lacquers & adhesives

Sealing compounds

A manufacturer of building chemical products needed a reliable pump for transferring sealing compounds as part of a production process. Various liquids and powder components are blended together in a mixer to make sealing compound. The pump conveys the sealing compound directly to a bucket filling unit or storage tank. The composition of the sealing compound (highly viscous and with latex added) puts extra heavy demands on the pump.

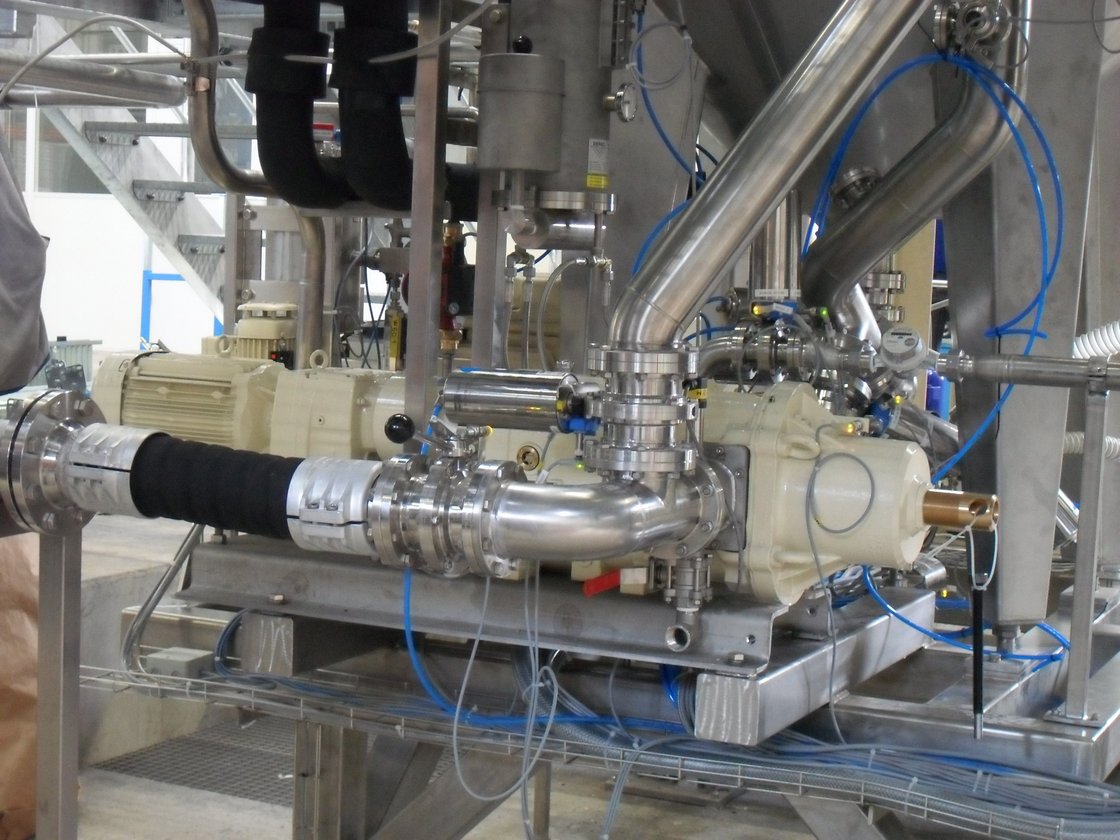

The customer opted for a Börger Protect Rotary Lobe Pump in stainless steel. Decisive factors for this choice were the material variety and ease of maintenance provided by the Börger pumps and especially the extensive experience of Börger GmbH in dealing with the challenges of chemical pumped media. The pump is equipped with double-acting mechanical seals. A Börger thermosyphon system is used for the pressurization of the double-acting mechanical seal.

While the bucket fills up, the volume flow is regulated by a bypass pipe to the mixing tank. This allows the pump to operate continuously. As an additional control for the excess pressure a Börger Variocap with inductive sensor is used.

Construction chemistry, paints, lacquers & adhesives

Adhesive dispersion

The customer sought a positive displacement pump to fill small containers with low pulsation and minimal shear action. The pump also had to have a seal which could cope with the hardened pumped medium.

The customer decided on a Börger Rotary Lobe Pump with a multi-seal-K mechanical seal.

Construction chemistry, paints, lacquers & adhesives

Emulsions

A leading Asian paint manufacturer required a pump in a new production plant for transferring highly sensitive latex-based emulsions. The emulsions needed to be pumped from storage tanks into the production plant. The pumps also needed to have a reduced width, slow speeds and a low NPSH value. The customer's priority was that the pumps would be easy to clean when changing from product to product.

After comprehensive tests with pumps from different manufacturers in an existing plant, the customer decided to install 22 Börger Rotary Lobe Pumps in the new plant. The wetted components of the pump are made of stainless steel. Premium stainless steel rotors are also used. The MIP (Maintenance in Place) design of the pumps allows the pumps to be easily maintained and cleaned.

Construction chemistry, paints, lacquers & adhesives

Glue

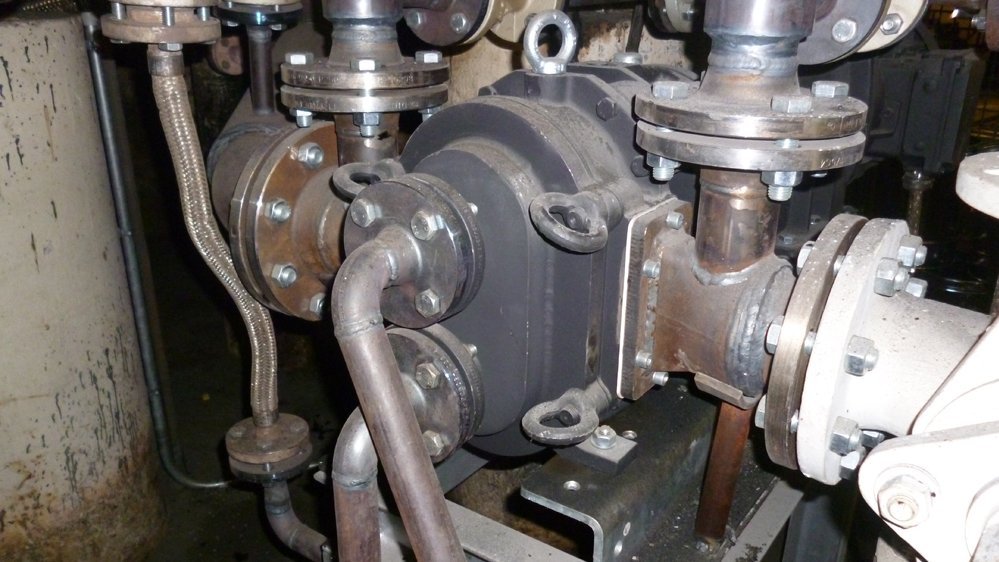

A pump was sought for conveying quick-drying glue through a two-stage filter system. The previously installed compressed air membrane pump was having problems with valve ball malfunction. Hose pumps were also having trouble in the same application with hardening particles. Pumps with mechanical seal are not suitable for this medium. The downtime of the double-acting mechanical seal was unacceptable.

Installing the Börger Rotary Lobe Pump with multi-seal-K meant that the service life of the rotor and shaft seal reached over 6000 hours under the challenging conditions of batch operation.

Construction chemistry, paints, lacquers & adhesives

Paints

A paint and varnish manufacturer uses a Börger Rotary Lobe Pump with packing mechanical seals in a paint mixing plant for pumping paint containing solvent.

The pump is installed with a mixer in a small room. Due to the explosive protection zone in the room, the Börger Rotary Lobe Pump has an ATEX-compliant design. To protect the packing seals from critical temperatures, both packing seals are monitored thermally by ATEX compatible temperature gages. If a critical temperature is reached, the pump is shut down via the control unit.

The various ingredients of the paint are blended together in a tank outside the EX room. The ingredients are transferred to a mixer by the Börger pump. After the mixer, the Börger Rotary Lobe Pump transfers the medium back to the tank. The Börger pump keeps the medium circulating until it has become a homogeneous mixture. A number of different paints and varnishes are blended in this plant. The speed of the pump can be adapted to the different viscosity of the pumped medium.

Construction chemistry, paints, lacquers & adhesives

Parquet and tile adhesive

A manufacturer of paint, varnish and special chemicals needed a high-performance pump to convey adhesive for tiles and parquet. The manufacturer previously used a piston diaphragm pump for this purpose. However, the capacity of the piston diaphragm pump rapidly dropped with the increasing viscosity of the pumped medium. The piston diaphragm pumps also generated high energy costs.

Because of the negative experience with the membrane pump, the chemical manufacturer wanted to test an alternative pump extensively before purchasing. The customer agreed with Börger GmbH to an eight-week test phase. Due to the very demanding characteristics of the pumped medium, a Börger Protect Rotary Lobe Pump with double-acting mechanical seal was installed. The pump is pressurized by means of a Börger thermosyphon system. The Börger Protect transfers the adhesive from a mixer into a storage tank or to their bottling process. During the transfer to bottling, a low pulsation and even transfer is essential.

After extensive testing, the customer accepted the machine and is now completely satisfied with the Börger Protect Rotary Lobe Pump. Pump capacity could be boosted by more than 150% with the Börger Protect, compared to the piston diaphragm pump previously installed. Energy costs have dramatically reduced.

Construction chemistry, paints, lacquers & adhesives

Textured plasters

A production facility for high-quality construction chemicals uses a Börger rotary lobe pump in a filling system for textured plaster. The prepared textured plaster is stored in a collection tank. From this tank the Börger rotary lobe pump conveys the plaster through a pivotable elastomer pipe to the filling station. A valve is installed at the end of the pipe. By means of the valve an employee of the company meters the quantity when filling the transport buckets. The rotational speed of the pump and thus the filling rate can be regulated by a frequency converter and adapted to the different sizes of the transport containers.

Construction chemistry, paints, lacquers & adhesives

Bitumen

In a production facility for construction materials containing bitumen, a Börger rotary lobe pump is used to convey the bitumen which reaches temperatures of up to 200 °C (392 °F). The pump feeds a filling station in 24-hour operation. The pump speed and the flow rate can be varied by means of a frequency converter. The bitumen is heated to a temperature of between 160 and 200 °C (320 - 392 °F) as the medium can be conveyed best at this temperature, having a viscosity of approx. 10,000 mPas. If the medium cools down, its viscosity increases to values of up to 100,000 mPas. In order to prevent the medium from cooling inside the pump, the Börger rotary lobe pump is equipped with a steam heater cover. The customer is very satisfied with the Börger rotary lobe pump.

Construction chemistry, paints, lacquers & adhesives

Floor potting compound

A construction chemistry company uses an ATEX-compliant Börger pump for conveying abrasive, filled binder. The rotary lobe pump conveys the highly viscous medium concentrated with Glass Bubbles and organic fillers with a pressure of up to 10 bar (145 psi) from the store over a longer distance to coloring. Compared to the service life of the compressed-air membrane pump used before, the service life has now improved by more than 400 %. In addition, maintenance work of the Börger pump is much easier and quicker. The noise level has been reduced as the Börger rotary lobe pump runs much more quietly than the pump used before.

Construction chemistry, paints, lacquers & adhesives

Tile adhesive

A company specializing in transporting chemicals was looking for a pump to convey tile adhesive. The highly viscous tile adhesive contains pigments in the dye. These pigments are very abrasive at high pressure. Therefore, the Börger Select Rotary Lobe Pump was fitted with stainless steel rotors.

Construction chemistry, paints, lacquers & adhesives

Adhesives

In a chemical factory, an eccentric screw pump was previously used to transfer adhesive. However, the eccentric screw pump was having trouble with the highly viscous medium. The adhesive manufacturer was not satisfied with the service life of the pump and sought a reliable replacement. The company decided on a Börger Select Rotary Lobe Pump with pressurized mechanical seals. A Börger Variocap was installed to protect against excess pressure.

Construction chemistry, paints, lacquers & adhesives

Fiber cement

A customer required an extremely robust rotary lobe pump to discharge highly viscous fiber cement sludge from a vacuum tank. The MIP features are particularly beneficial here: replacing the worn casing liners can be done in a very short time due to fast access via the quick-release cover.