Resistant to solids

Durable if pumped medium contains large amounts of sand.

For highly viscous media

Even highly viscous media can be conveyed with little effort.

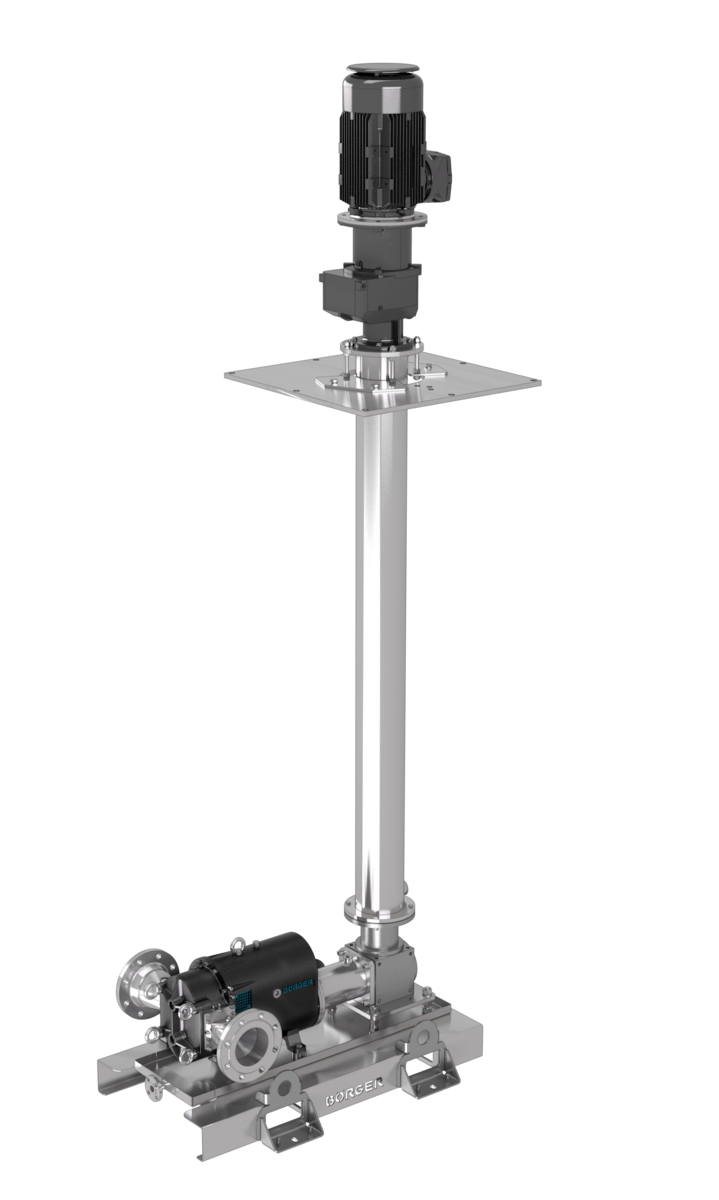

Installation length of more than 14 m

Börger semi-submerged pumps can be built with a coupling length of 14 m and more.

Resistant to chemicals

Even chemically aggressive media can be conveyed without any problems.

Gentle pumping

Shear-sensitive media are pumped gently.

Compact and powerful

Despite their compact size, the pumps are very powerful.

Customized

Each pump is configured and built individually.

ATEX-compliant

An ATEX-compliant pump design is available for use in potentially explosive atmospheres.