Construction

Done in just a few days

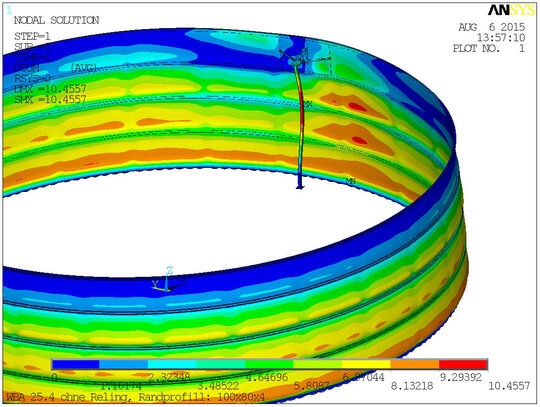

The Börger stainless steel tank consists of individual segments (1.50 x 3.00 m) which are bolted to one another.

Joined together horizontally, the individual plates are stabilized by the peripheral U-profile. The cylindrical tank is constructed, attached and permanently sealed onto a smooth flat base plate.

| Type | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Cyl. Height (m) | 1.50 | 3.00 | 4.50 | 6.00 | 7.50 | 9.00 | 10.50 | 12.00 | ||

| Ø (m) | Area (m²) | |||||||||

| 04 | 3.71 | 11 | 32 m³ | 49 m³ | 65 m³ | 81 m³ | 97 m³ | 114 m³ | 130 m³ | |

| 05 | 4.63 | 17 | 51 m³ | 76 m³ | 101 m³ | 126 m³ | 152 m³ | 177 m³ | 202 m³ | |

| 06 | 5.56 | 24 | 36 m³ | 73 m³ | 109 m³ | 146 m³ | 182 m³ | 219 m³ | 255 m³ | 291 m³ |

| 07 | 6.48 | 33 | 49 m³ | 99 m³ | 148 m³ | 198 m³ | 247 m³ | 297 m³ | 346 m³ | 396 m³ |

| 08 | 7.41 | 43 | 65 m³ | 129 m³ | 194 m³ | 259 m³ | 323 m³ | 388 m³ | 453 m³ | 517 m³ |

| 09 | 8.34 | 55 | 82 m³ | 164 m³ | 246 m³ | 328 m³ | 410 m³ | 492 m³ | 574 m³ | 656 m³ |

| 10 | 9.26 | 67 | 101 m³ | 202 m³ | 303 m³ | 404 m³ | 505 m³ | 606 m³ | 707 m³ | 808 m³ |

| 11 | 10.19 | 82 | 122 m³ | 245 m³ | 367 m³ | 489 m³ | 612 m³ | 734 m³ | 856 m³ | 979 m³ |

| 12 | 11.12 | 97 | 146 m³ | 291 m³ | 437 m³ | 583 m³ | 728 m³ | 874 m³ | 1,020 m³ | 1,165 m³ |

| 13 | 12.04 | 114 | 171 m³ | 342 m³ | 512 m³ | 683 m³ | 854 m³ | 1,025 m³ | 1,195 m³ | |

| 14 | 12.97 | 132 | 198 m³ | 396 m³ | 595 m³ | 793 m³ | 991 m³ | 1,189 m³ | 1,387 m³ | |

| 15 | 13.89 | 152 | 227 m³ | 455 m³ | 682 m³ | 909 m³ | 1,136 m³ | 1,364 m³ | ||

| 16 | 14.82 | 173 | 259 m³ | 517 m³ | 776 m³ | 1,035 m³ | 1,294 m³ | 1,552 m³ | ||

| 17 | 15.75 | 195 | 292 m³ | 584 m³ | 877 m³ | 1,169 m³ | 1,461 m³ | 1,753 m³ | ||

| 18 | 16.67 | 218 | 327 m³ | 655 m³ | 982 m³ | 1,310 m³ | 1,637 m³ | 1,964 m³ | ||

| 19 | 17.6 | 243 | 365 m³ | 730 m³ | 1,095 m³ | 1,460 m³ | 1,825 m³ | 2,190 m³ | ||

| 20 | 18.53 | 270 | 405 m³ | 809 m³ | 1,214 m³ | 1,618 m³ | 2,023 m³ | 2,427 m³ | ||

| 21 | 19.45 | 297 | 446 m³ | 891 m³ | 1,337 m³ | 1,783 m³ | 2,228 m³ | |||

| 22 | 20.38 | 326 | 489 m³ | 979 m³ | 1,468 m³ | 1,957 m³ | 2,447 m³ | |||

| 23 | 21.3 | 356 | 534 m³ | 1,069 m³ | 1,603 m³ | 2,138 m³ | 2,672 m³ | |||

| 24 | 22.23 | 388 | 582 m³ | 1,164 m³ | 1,747 m³ | 2,329 m³ | 2,911 m³ | |||

| 25 | 23.16 | 421 | 632 m³ | 1,264 m³ | 1,896 m³ | 2,528 m³ | 3,160 m³ | |||

| 26 | 24.08 | 456 | 683 m³ | 1,366 m³ | 2,049 m³ | 2,732 m³ | 3,416 m³ | |||

| 27 | 25.01 | 491 | 737 m³ | 1,474 m³ | 2,211 m³ | 2,948 m³ | 3,684 m³ | |||

| 28 | 25.94 | 528 | 793 m³ | 1,585 m³ | 2,378 m³ | 3,171 m³ | 3,964 m³ | |||

| 29 | 26.86 | 567 | 850 m³ | 1,700 m³ | 2,550 m³ | 3,400 m³ | 4,250 m³ | |||

| 30 | 27.79 | 606 | 910 m³ | 1,820 m³ | 2,729 m³ | 3,639 m³ | 4,549 m³ | |||

| 31 | 28.71 | 648 | 971 m³ | 1,942 m³ | 2,913 m³ | 3,884 m³ | 4,855 m³ | |||

| 32 | 29.64 | 690 | 1,035 m³ | 2,070 m³ | 3,105 m³ | 4,140 m³ | 5,175 m³ | |||

| 33 | 30.57 | 734 | 1,101 m³ | 2,202 m³ | 3,303 m³ | 4,404 m³ | ||||

| 34 | 31.48 | 779 | 1,167 m³ | 2,335 m³ | 3,502 m³ | 4,670 m³ | ||||

The suitable stainless steel for each application

To be able to build a tank which is perfectly suited for any type of stored liquid, we offer our stainless steel tanks in various materials.

High-quality stainless steels and solid wall thicknesses guarantee a long service life along with maximum lasting value while giving you peace of mind knowing that you have opted for the right tank.

Always the best solution

Thanks to various capacities, materials, roof variations, mixers and other attachment parts, Börger tank systems can be designed such that they are perfectly suited for your application:

• Process water tanks

• Sludge tanks

• Liquid manure storage

• Aeration basin

• Biogas fermenter or final storage

• Digestion tower

• Storage for liquid feed or moist cereal

• Fire-extinguishing water storage

• Liquid fertilizer storage

• Storage tank for liquids of any type

• etc.

The stainless steel tank with DIBt approval

Börger stainless steel tanks have the DIBt approval for JGS systems The German Institute for Building Technology (DIBt) has granted us DIBt approval for liquid manure/slurry silage (JGS) systems.

Benefits:

• Simplified granting of a building permit

• Prerequisite for applying for state subsidies

• Pre-designed and regulated expert inspection

• Regulated leakage detection system

• Tested construction system

• Sealing system tested for durability

• Use of various approved sealants

Background:

The new “Storage Ordinance for the Handling of Substances Hazardous to Water” (AwSV) came into force on August 1, 2017 and serves as the basis for approval procedures for slurry storage tanks. It applies nationwide and has replaced the previous state-specific regulations. In this context, it was stipulated that only approved components, construction systems and container systems may be used for the construction of storage facilities for JGS. After a lengthy process with many individual tests, the DIBt granted us DIBt approval in 2021 as the only manufacturer of steel and stainless steel containers to date.

Case Studies

Practical example

Whether it's in industry, wastewater treatment, agriculture or biogas – Börger stainless steel tanks are stable in value and maintenance-free solutions for storing liquids.

The industries and applications listed here will give you an impression of the versatility of Börger stainless steel tanks.

Wastewater for MAP precipitation

A wastewater treatment plant was looking for suitable tanks for the precipitation of magnesium ammonium phosphate (MAP) from municipal digested sludge.

Phosphorus is recovered during this chemical process. The customer opted for two Börger stainless steel tanks. They were convinced by the variety of possible stainless steel qualities and the consulting offered by Börger. Following a thorough analysis of the digested sludge composition, the suitable stainless steel and sealant were selected. Thanks to the segmental design, the tanks could be set up very quickly.

They are equipped with an insulation and a multi-colored trapezoidal sheet cladding. The gas-tight stainless steel roof protects the environment from emissions. The 1 m x 2 m (3.2 x 6.5 feet) pressure doors allow the customer easy access to the emptied tanks.

Leachate

The operators of a landfill were looking for suitable tanks to store the leachate occurring in the plant. The PE tanks used so far had become too small.

The customer opted for three Börger stainless steel tanks. Depending on the rainfall, different amounts of leachate with varying pollutant concentrations occur at the landfill. The stainless steel tanks are lined on the inside with HDPE sheets to protect the stainless steel from the often highly concentrated pollutants. The plastic sheets could be fastened without any problems to the horizontal screw connections.

Thanks to the self-supporting roofs, a roof support was not required, which made laying of the flooring material so much easier. The semi-annual inspections can be carried out quickly and easily through the manholes in the tanks.

Liquid manure storage

For the storage of liquid manure, a farmer opted for two Börger stainless steel tanks with a capacity of 2,528 m³ (11,130 usgpm/h) each. By using two storage tanks the farmer is able to reduce the content of phosphorus in the liquid manure by means of a special sedimentation process.

In addition to the high quality of the Börger tanks the customer was convinced in particular by the lasting value as well as the option to increase the capacity of the tanks later on.

Due to current legislation the tanks were equipped with a roof for emission protection. For tanks without a roof retrofitting is possible anytime with ease.

Fermenter

The operator of a biogas plant was looking for three new tanks for the facility. They were to be used as a beet store, a fermenter and final storage tank. The tank for final storage needed to have a volume of 5,000 m³ (22,014 usgpm/h).

The customer opted for three Börger stainless steel tanks. The customer was particularly impressed with all the options available for Börger stainless steel tanks. The customer could select the perfect solution for his requirements from the wide range of different covers. The plan is to extend the beet tank from the current storage capacity of 1,895 m³ up to 2,527 m³ (8,343 - 11,126 usgpm) in 2015.

The stability of the stainless steel tank and the option of dismantling it to assemble in another location gave the operator of the biogas plant financial security should the guaranteed payments for power feed into the power under the terms of the German Renewable Energy Act end after 20 years.