Other Industries

Lubricating oil

An Italian power company uses recycled fuel to produce electricity.

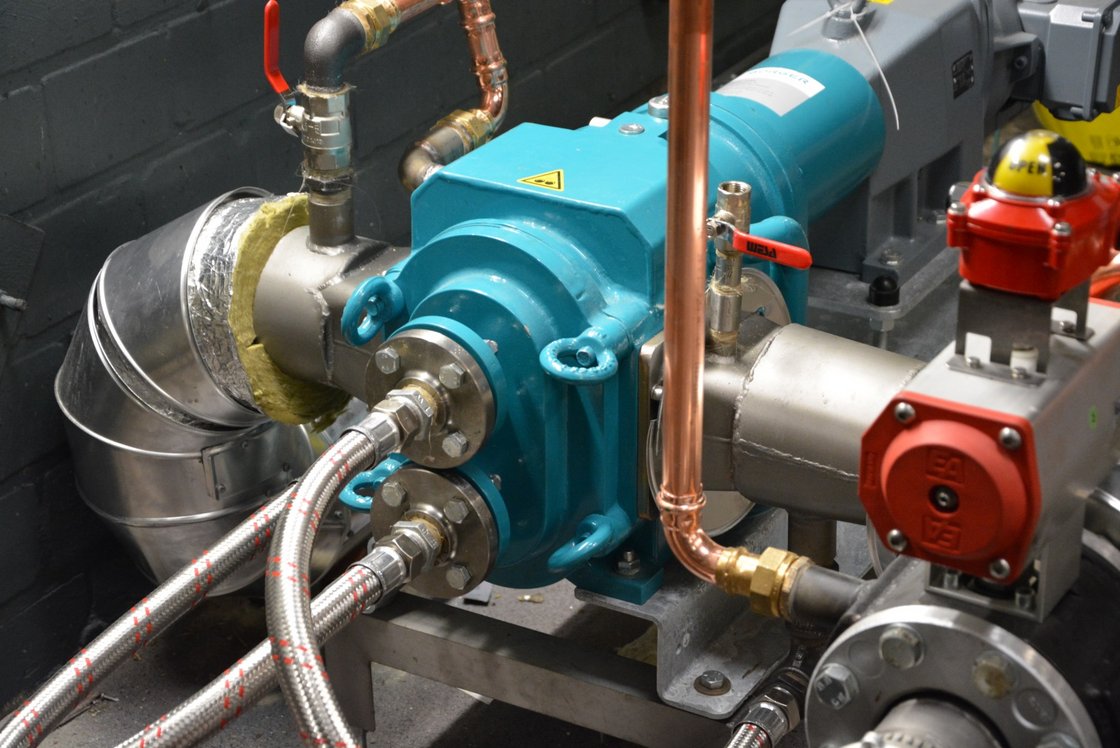

The fuel supplies the energy for a 15,000 hp diesel engine which drives a power generator. Two rotary lobe pumps ensure that the engine is constantly supplied with oil. One of the pumps circulates the oil continuously, cooling and lubricating the engine. To this end, the oil is pumped through a filter system and a heat exchanger, which regulates the temperature of the lubricating oil.

The other pump serves as a spare pump, so that engine cooling can be ensured also during maintenance. Due to the confined space, the pumps are arranged vertically.

Other Industries

Water glass (sodium silicate)

A manufacturer of moldings for cupola and shaft furnaces uses Börger BLUEline Nova rotary lobe pumps to convey water glass in its production plant.

The water glass serves as a binder for the pulverized coal of a new type of briquette. Pump 1 conveys the water glass from a storage tank into an intermediate container. Pump 2 is used to feed the mixer below via nozzles. Water glass places high demands on the mechanical seal because it hardens very quickly on contact with air. For this reason, the stainless steel pumps are equipped with double-acting mechanical seals. The seals are pressurized by means of a barrier pressure supply system.

Other Industries

Secondary fuels

A South Korean cement plant uses an ONIXline Rotary Lobe Pump for charging the furnaces with secondary fuels.

Due to the high chemical stress caused by the secondary fuels containing solvents, the pump casing of the ONIXline pump is made of stainless steel. A replaceable casing lining protects the pump casing from wear caused by abrasive components in the pumped media with high solids content.

The stainless steel rotors with screw profile convey the fuels very evenly and with low pulsation. The service life is significantly better than that of the gear pump used before. In addition, maintenance work requires a lot less time and effort.

Other Industries

Impregnating resins

A manufacturer of wind turbines uses three Börger Rotary Lobe Pumps for conveying impregnating resins. Resin is used for sealing certain components (rotor and stator parts, windings). The Börger pumps transfer the resin from a storage tank to an impregnating vat.

The components that need to be sealed are heated and immersed in the impregnating vat of resin. The heat then causes the resin to harden on the heated components. After impregnating, the components are removed from the vat. To prevent the remaining resin from hardening in the vat, it needs to be pumped back to the storage tank as quickly as possible.

When constructing the plant, the wind turbine manufacturer sought a pump which would be able to convey the highly viscous resin, be low on space and which could achieve a very high pump output if the impregnating vat had to be emptied in an emergency. The customer decided on three Börger Rotary Lobe Pumps. The pumps were assembled vertically to prevent any medium deposits in the pipes.

Other Industries

Bentonite

A civil engineering company increasingly uses trenchless installation technology. This special technology allows pipes, electrical cables etc. to be installed without having to dig trenches. One company specializing in this technology works with the horizontal directional drilling (HDD) method. A horizontal flushing bore is made in the ground which can be controlled using modern detection technology. Flushing nozzles are attached to the drill head. Bentonite is then fed into the hole through the nozzles. The Bentonite flushes the bore hole to stabilize the bore channel and cool the drill head.

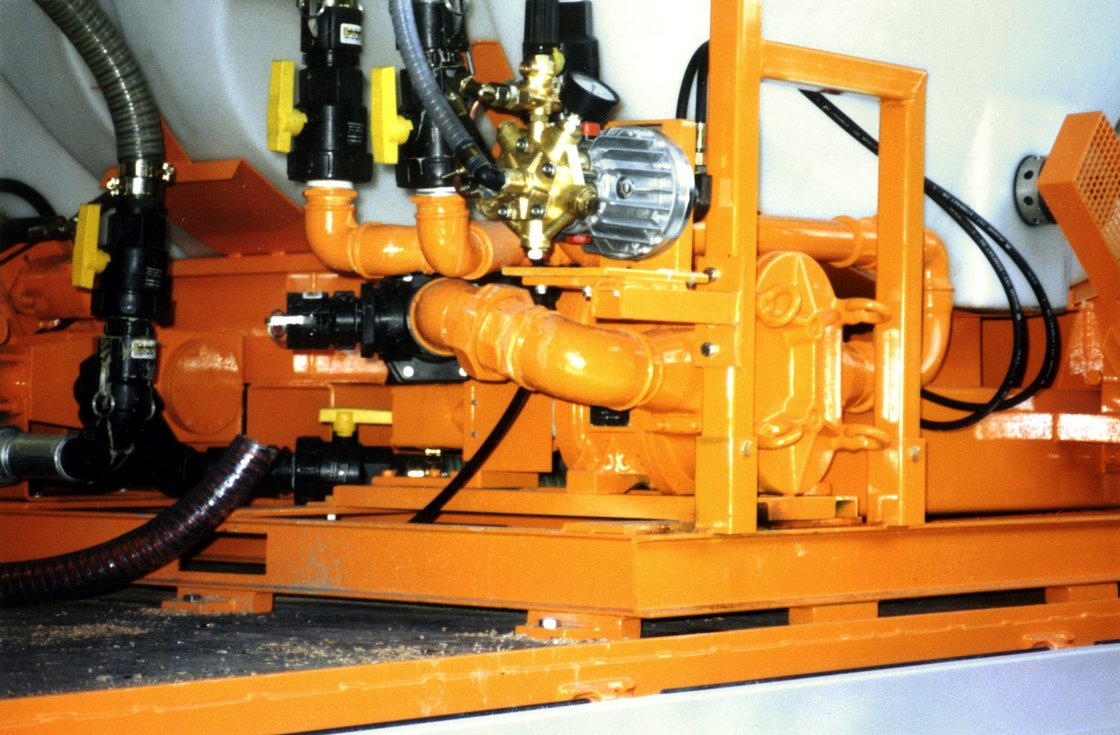

The horizontal flushing bore rig is installed on the company's operation vehicle which also accommodates a Börger Rotary Lobe Pump for pumping the bentonite from the tank to the drill head. The plant engineer emphasized the need for a pump with a long service life, high resistance to wear and one that is very user-friendly in the event of maintenance. The plant engineering company and their customer are highly satisfied with the Börger Rotary Lobe Pump. They have since installed over 100 Börger Rotary Lobe Pumps in horizontal flushing bore rigs.

Other Industries

Sizing

A textile manufacturer had persistent problems with its centrifugal pumps used for conveying sizing. The centrifugal pumps had sealing problems when conveying the sizing containing fibers. The textile manufacturer decided to replace the centrifugal pumps by Börger rotary lobe pumps. One of the three Börger rotary lobe pumps conveys the sizing into the sizing machines. In the sizing machine the threads are immersed through the sizing basin. Continuous circulation is required so that the sizing will maintain its consistence in the machine. To this end, two more Börger rotary lobe pumps are used.

Other Industries

Hard fat

An animal feed manufacturer was looking for a powerful pump for conveying palm stearin, a hard fat used for the production of animal feed. Since the hard fat has a melting point of approx. 60 °C (140 °F), it was important that the pump, the piping, the shut-off valves, etc. were well heated to prevent hardening of the palm stearin. Based on the good experience made with Börger products, the company opted for a Börger rotary lobe pump. In order to prevent the medium from hardening, the rotary lobe pump is equipped with a steam heater cover and a heated pump casing.

Other Industries

Lignite opencast mining

A large energy company extracts lignite on its mining fields in opencast mining operation using a special excavation and conveying technology. Compared to other methods in which the soil layers covering the lignite are transported around the surface mine using belt conveyor systems, this technology requires much shorter transport routes. These short transport routes are elementary for a productive excavation of the lignite and are highly frequented. The energy company uses a mobile Börger rotary lobe pump for pumping out the water accumulations. The pump is resistant to solids and is installed on a three-point hitch frame.

Other Industries

Wellpoint dewatering

A manufacturer of pumping stations has specialized in the production of mobile units e.g. for wellpoint dewatering. To this end, rotary lobe pumps are installed on a steel base frame. Depending on the application, Börger pumps of different sizes are used. Upon request, the pumps are driven by a diesel, electric or hydraulic motor. The customer is very satisfied with the Börger rotary lobe pumps. The long service life, the energy-efficient operation and the ease of maintenance have convinced the customer.

Other Industries

Hydrogen sulfide

A leading provider of catalysts for oil refineries and petrochemical processing companies needs hydrogen sulfide for the treatment of various catalysts. It was necessary to manufacture the pump casing and the rotors of the Börger pumps used from Hastelloy due to the aggressive pumped medium. The three pumps are installed on top of each other with minimum space requirements in order to maintain the pumps without having to stop the production process. One pump is used as a reserve pump. The pumps have an ATEX-compliant design and are permanently technically tight pursuant to TA Luft.

Other Industries

Press water

A manufacturer of steel pipes uses rotary lobe pumps to feed a water pressure accumulator with press water, an emulsion with lubricating and antibiotic additives. A constant flow rate with alternating counter pressures is very important. Pressures of up to 10 bar (145 psi) are to be handled. The pumps are equipped with customized tri-lobe steel rotors with screw profile. An electronic overpressure protection protects the pumps from excessive counter pressure.

Other Industries

Fango material

Due to the minerals contained and thermophysical properties, fango mud removed from mud lakes is used in physiotherapy practices, spa clinics and rehabilitation centers for various therapies. In various international sanatoria Börger rotary lobe pumps are used to convey the highly viscous fango material in their own moor mud processing systems The pumps convey the mud into the processing systems. After the mud has been processed, the Börger pumps convey the fango material into a circular pipeline for filling the baths.

Other Industries

Skimmer pump

Oil spill emergencies require quick corrective action. Damage might be devastating and irreversible. In order to be able to pump fully independently, the mobile skimmer pump is equipped with a diesel engine. Due to its compact design, the Börger pump can be installed into the mobile plant very easily. The low weight of the aluminum pump makes operation easier. In addition, the Börger rotary lobe pump conveys media with minimum shearing effect. Oil and water are hardly emulsified during pumping.

Other Industries

District heating water

A large German city uses a Börger mobile pump to empty district heating pipelines in case of extensive stoppages. The Börger pump does not have to be installed in the vault but is placed above the utility vault and sucks in the hot water. In case of special demanding physical conditions, cooler water (e.g. from the return line) can be supplied to the pump through an additional connection. Due to the mixture, the temperature of the pumped medium decreases.

Other Industries

Brine suspension

Backfilling of hollow spaces is necessary to secure jeopardized pit hollow spaces in former salt mines. The liquid backfilling material is conveyed through pipelines underground and to the mining caverns. Liquid brine accumulates in small salt ponds during hardening. This brine suspension has to be pumped upwards for further processing. A company which has specialized in backfilling operations uses Börger rotary lobe pumps for this. The very compact pumps are transported underground where they suck in the saturated brine with minerals from a depth of up to 7 m (22.9 ft) and pump them for further use. Heights of between 60 and 80 m (196.8 - 262.5 ft) are overcome in the process.

Other Industries

Bone particles

In the production of gelatine, large particles of bone are fed into a warm acid (ph ~4) in close distribution as a liquid suspension. To prevent problems at a later stage of processing, this must take place extremely gently. A Börger Rotary Lobe Pump in stainless steel and with short seal lines is perfectly suited to deal with these requirements.