One Powerfeed for any number of tanks

The Powerfeed is integrated at a suitable point in the piping system, so that a powerful biogas pump can extract recirculate from the requested tank. The Börger feeding technology feeds the biomass in doses into the flow pipeline in the fully enclosed system. The recirculate enriched with biomass is conveyed into the requested fermenter.

New Mulit Disc Technologie

Lässt sie durchschlafen

Die patentierte Multi Disc Technologie wird seit Jahren erfolgreich bei den Bioselect Separatoren eingesetzt.

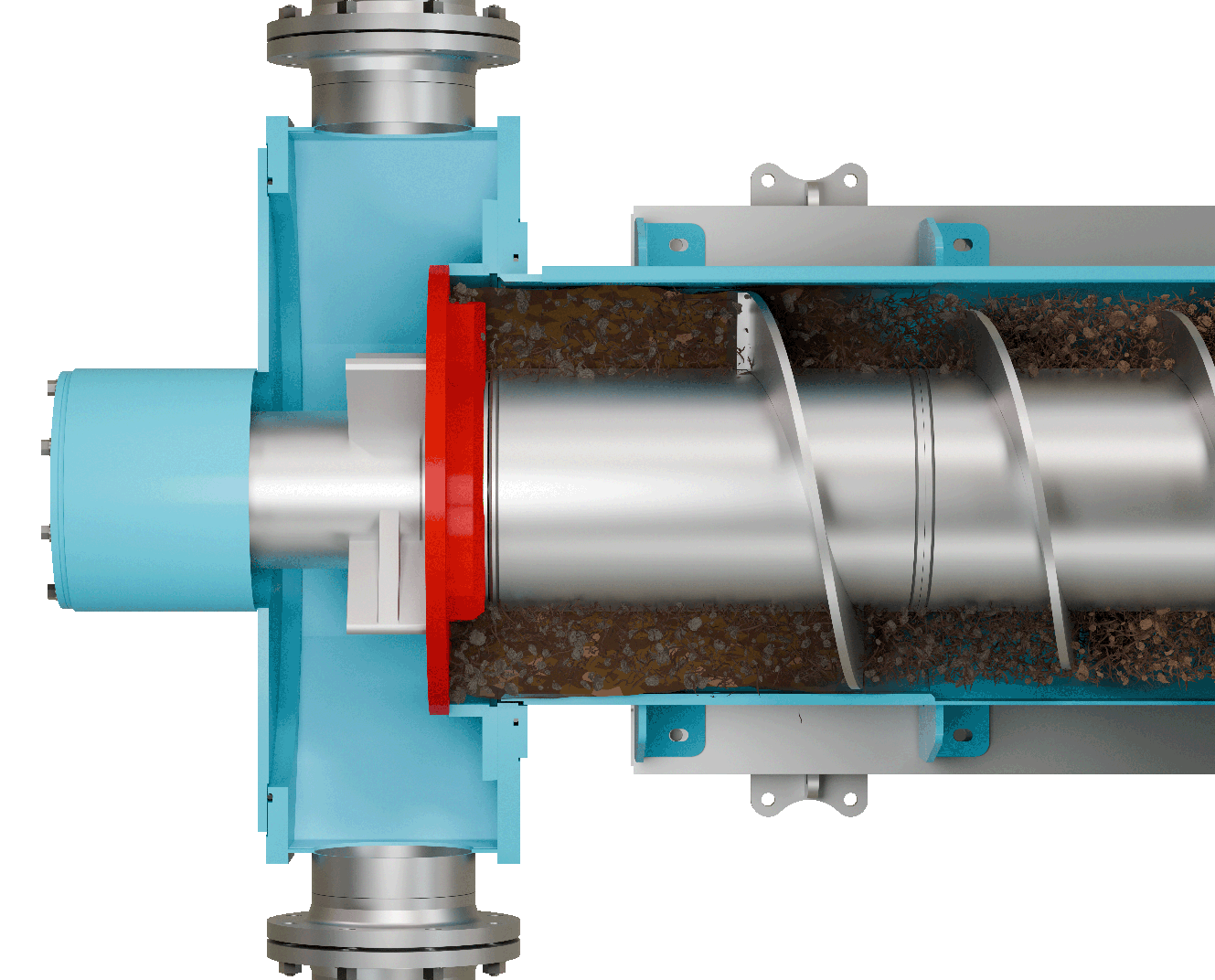

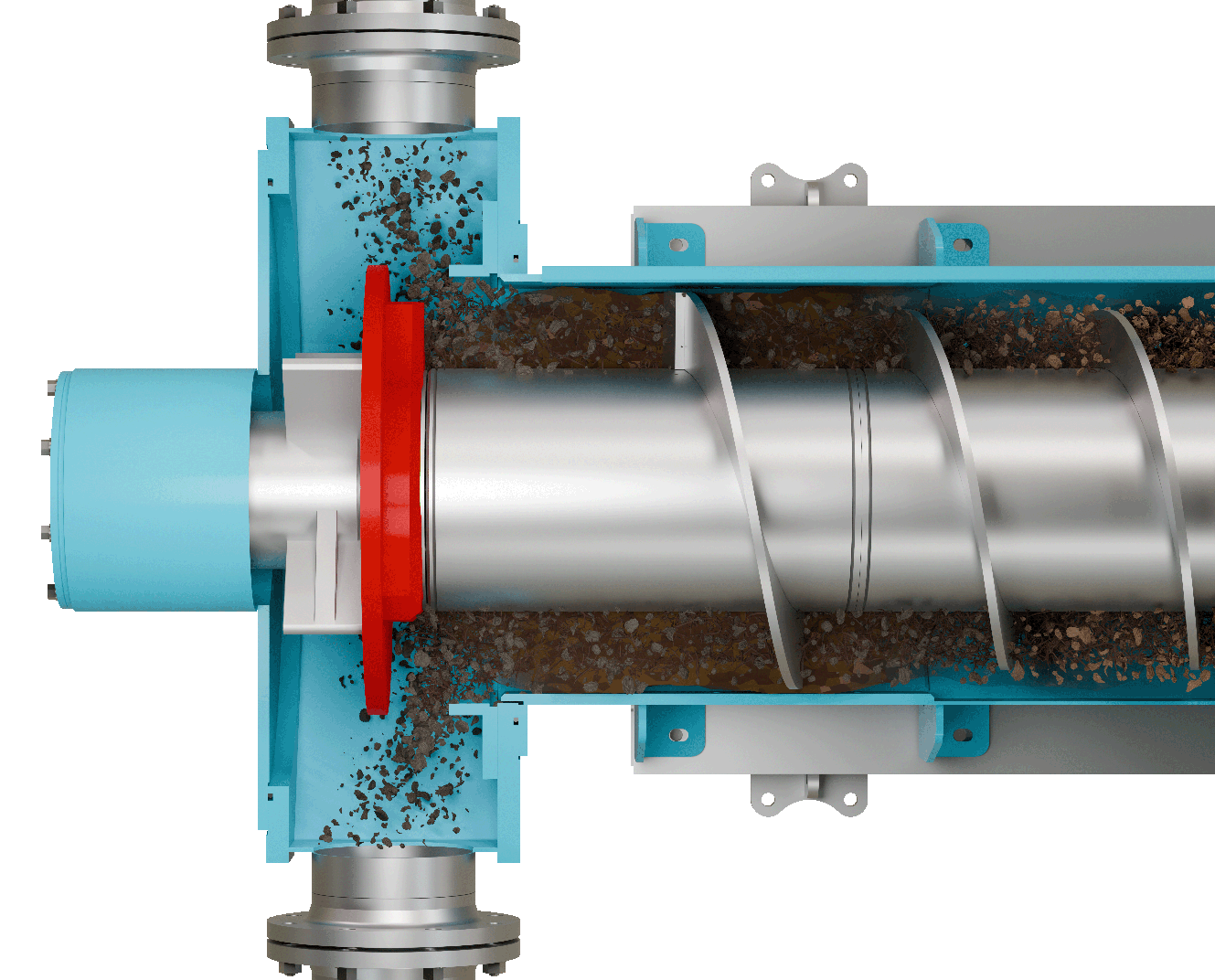

Die Multi Disc verschließt den Presskanal sicher, bis sich ein stabiler Biomassepfropfen gebildet hat. Erst dann öffnet sich die Multi Disc – die Biomasse wird kontrolliert in den Rezirkulatstrom eingebracht. Eine intelligente Steuerung überwacht permanent die Verpressung im abdichtenden Pfropfen. Ist dieser aufgrund wechselnder Beschaffenheit der Biomasse nicht mehr ausreichend stabil, verringert die Multi Disc den Eintragsspalt automatisch.

Diese durchbruchsichere Technik sorgt unabhängig von Struktur und Feuchtegehalt der Biomasse für:

maximale Sicherheit

exakte Dosierung

störungsfreien Dauerbetrieb

One Powerfeed for all containers

With a Powerfeed you can feed tanks of any number and of different heights.

The Powerfeed and a high-capacity biogas pump form the central unit of the liquid feeding technology.

The tanks of the biogas plant are connected to the pump via pipe and valve systems, so that the pump can extract recirculate from the requested tank.

Fine breakdown of the biomass

Inside the Powerfeed, the biomass is compressed and broken down very finely before it is fed into the system.

This concept releases any trapped air from the biomass. The fine biomass particles have a large surface and ensure a higher gas yield. In addition, less floating layers are formed in the tank which results in energy savings due to reduced agitating effort.

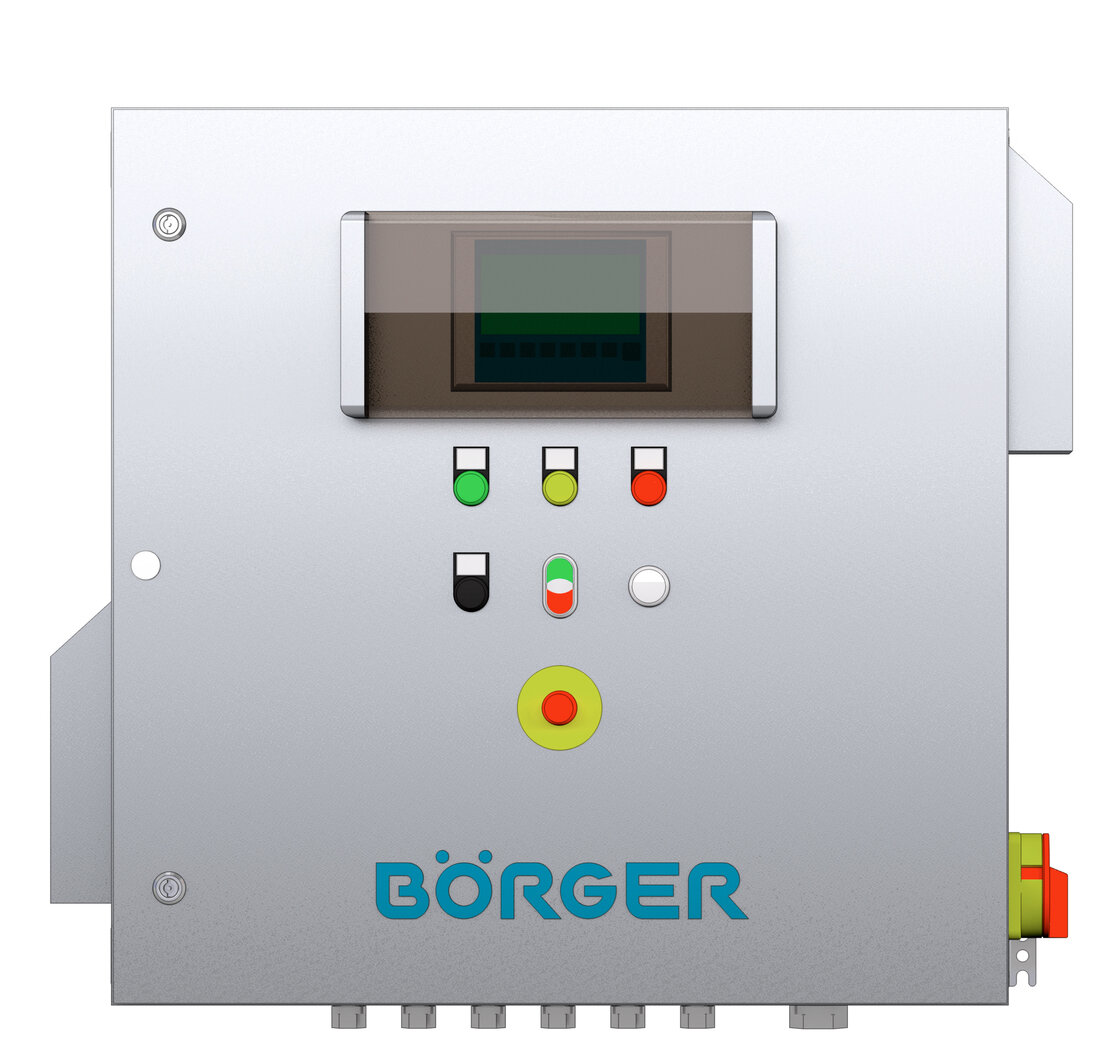

- Ideal coordination of the operation of all components (e.g. Powerfeed, recirculation pump, auger feed, etc.)

- Protection of the entire system (pressure monitoring, dry run protection, function monitoring, etc.)

- Integration via bus system (Profinet, Profibus, etc.)

- Simple entry and user administration via touch display

- External control by operator possible via mobile communication, WLAN, DSL (remote maintenance by Börger is also possible)

- and so on

Safe. Flexible. Ease of maintenance.

- Highest level of safety, liquid penetration almost impossible due to the design

- One system for different biomass types

- Can be retrofitted in any biogas plant

- Very easy to maintain

- Everything from a single source – Powerfeed, recirculation pump, control technology and macerator

Solids feeding

An agricultural holding was looking for reliable feeding technology for transferring corn silage to a biogas plant.

After scrutinizing the feeding technology of various providers, the biogas plant operator chose the Börger Powerfeed 400. The customer was impressed with the renowned high quality of the Börger products, particularly the entirely closed system, the uncomplicated, easy controls and the Powerfeed design which prevents gas from escaping.

The customer chose a Börger Biogas Rotary Lobe Pump to convey the recirculate. The customer is extremely pleased with the Börger Biogas Rotary Lobe Pump and the Powerfeed 400. The long service life and easy handling ensure efficient operation of the biogas plant.