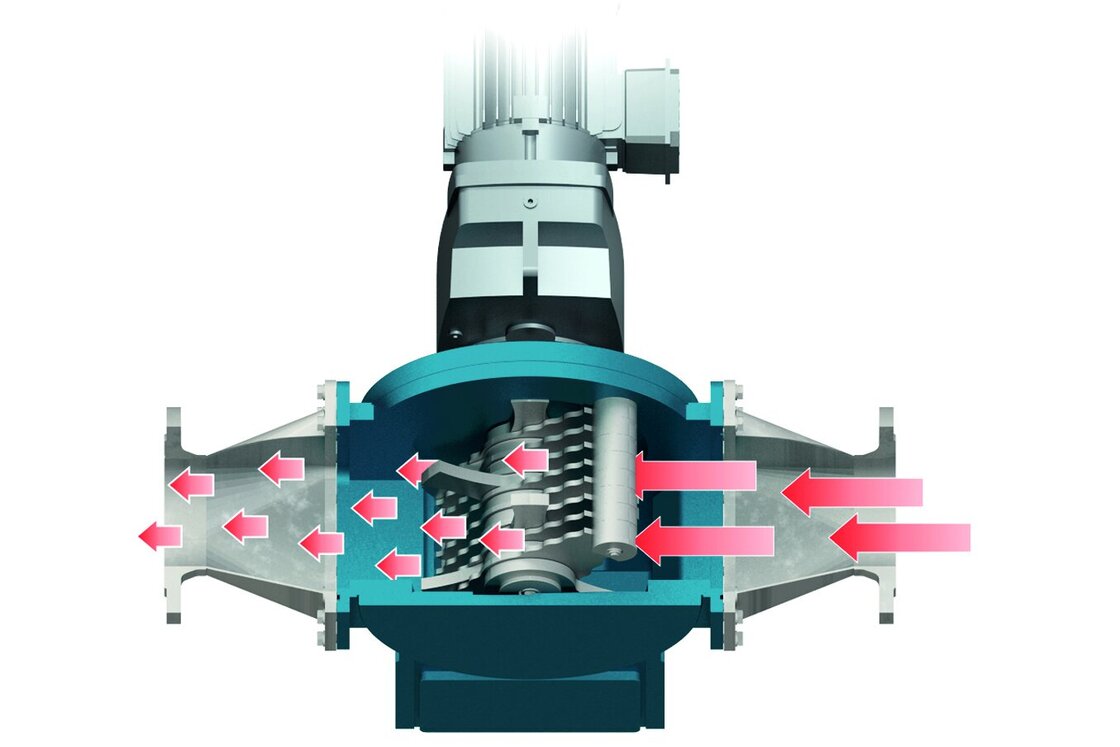

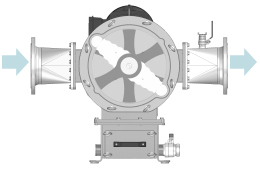

Rotating blades are also able to shred coarse solids

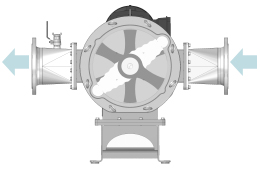

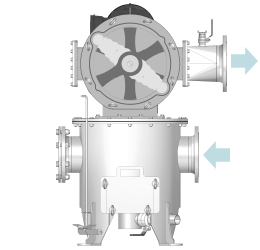

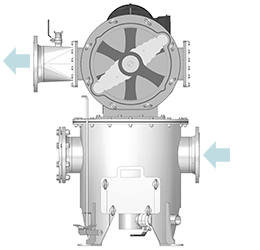

The liquid fed in with the solids flows through the stationary counter blades which are arranged at an angle. The solids are captured by the counter blades and shredded by the rotating blades.

The macerated solids then continue to flow with the liquid.

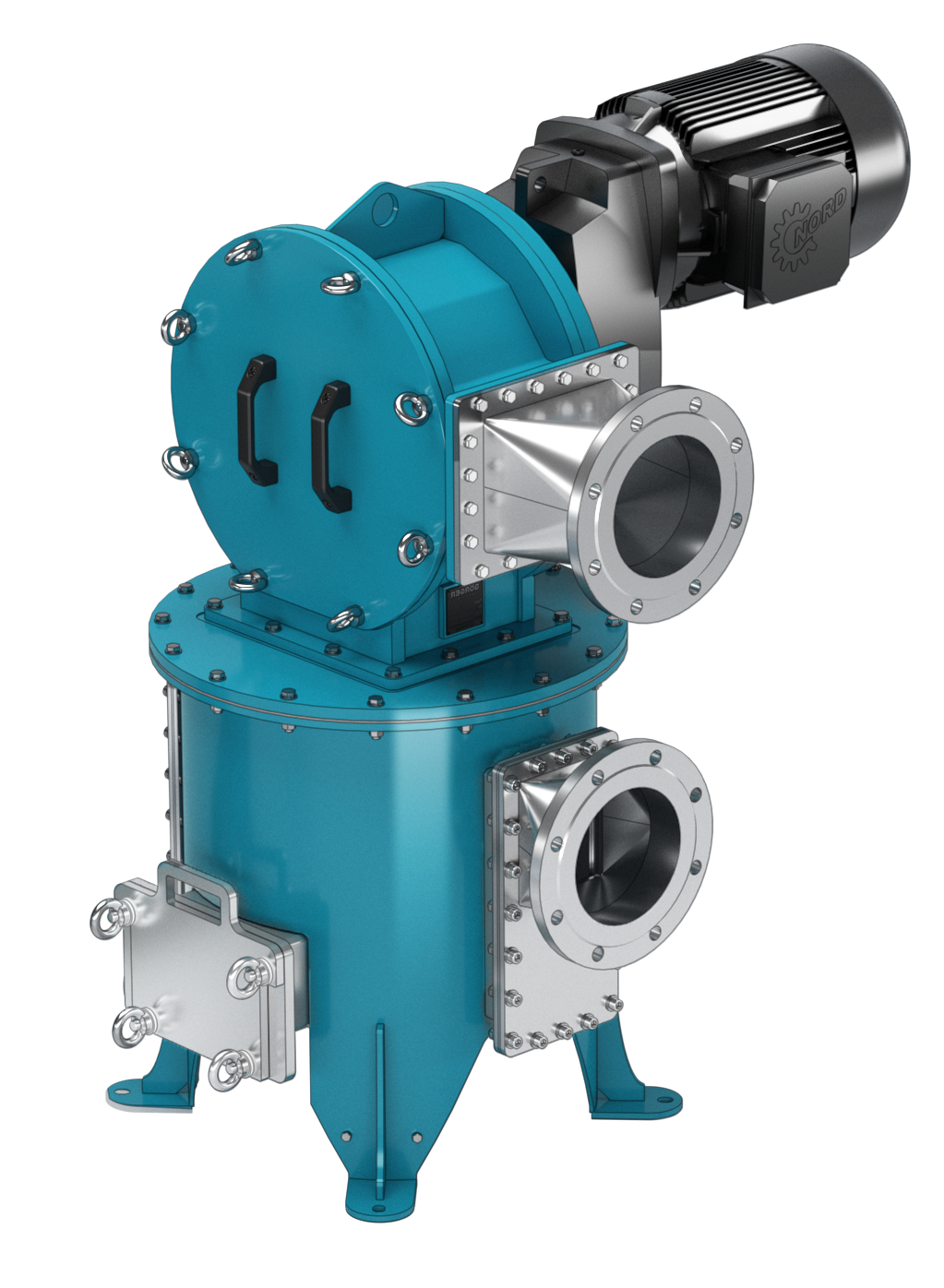

Coarse objects which cannot be chopped are ejected into the debris collector.

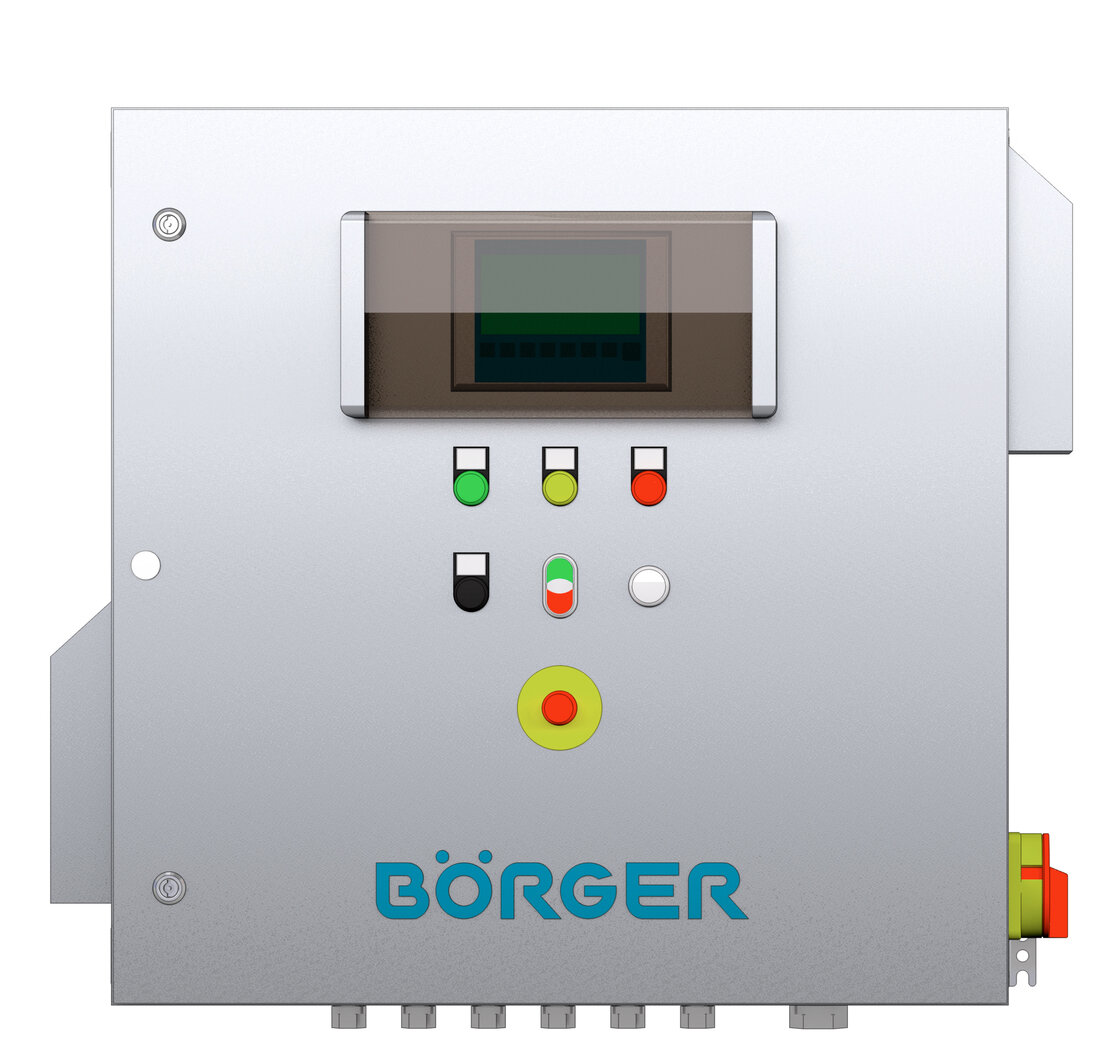

- Highest degree of operational safety due to reversing control (load- and/or time-dependent reversing)

- Easily adjustable reversing parameters

- External control by operator possible via smartphone, WLAN, DSL (remote maintenance by Börger is also possible)

- Production data acquisition

- Simple entry and user administration via touch display

- Module or control cabinet solutions

- Integration via bus system (Profinet, Profibus, etc.)

- Heavy and extremely heavy duty starting possible

- and so on

The Börger Rotorrakes can be used in potentially explosive atmospheres in accordance with the ATEX Directive.

The ATEX Directive 94/9/EC defines the prescribed technical requirements for equipment and protective systems intended for use in potentially explosive atmospheres in Europe.

Air Pollution Control Act

The Rotorrake can be used for lawfully handling toxic and highly toxic media in accordance with the Air Pollution Control Act.

The technical guideline for air quality control is the German government's “first general administrative regulation under the federal Air Pollution Control Act”.

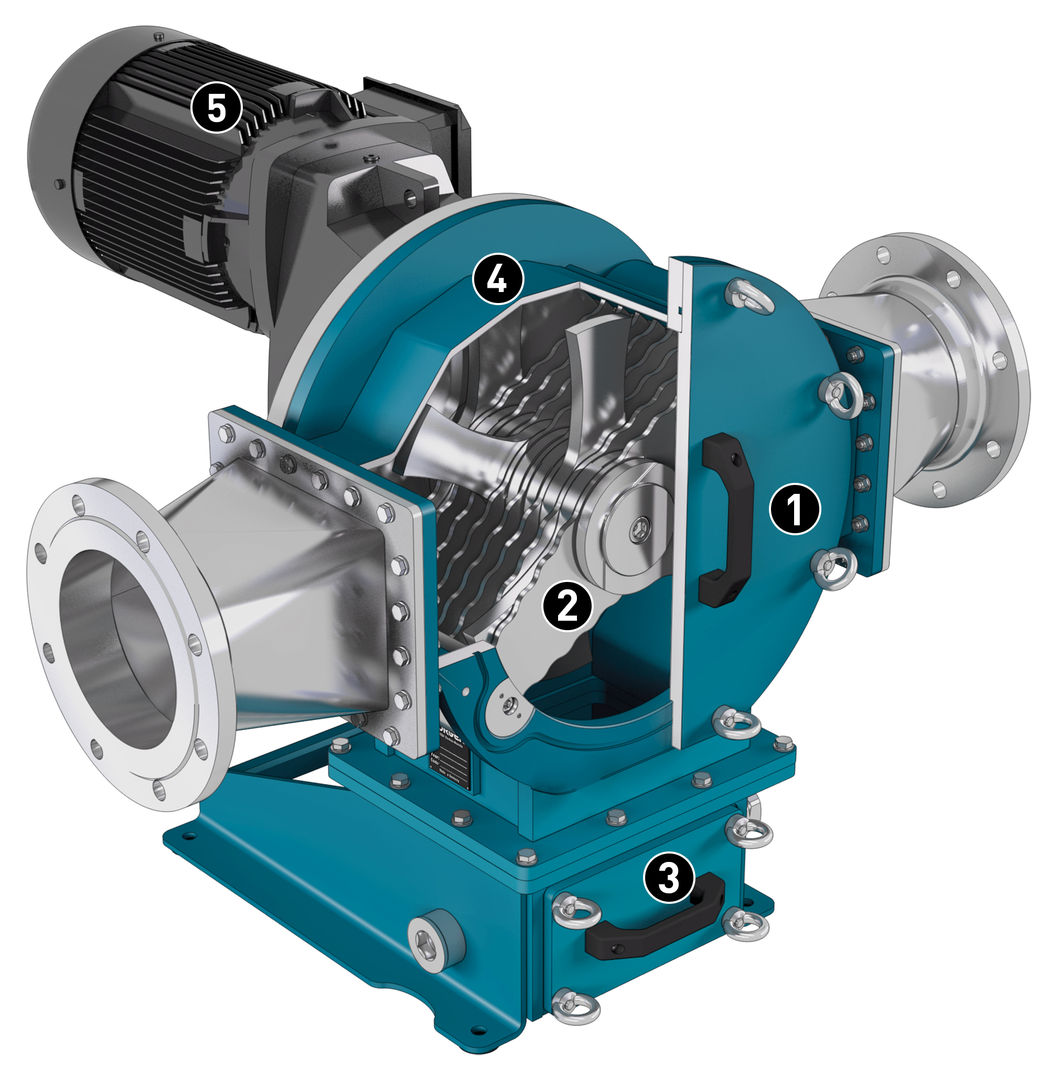

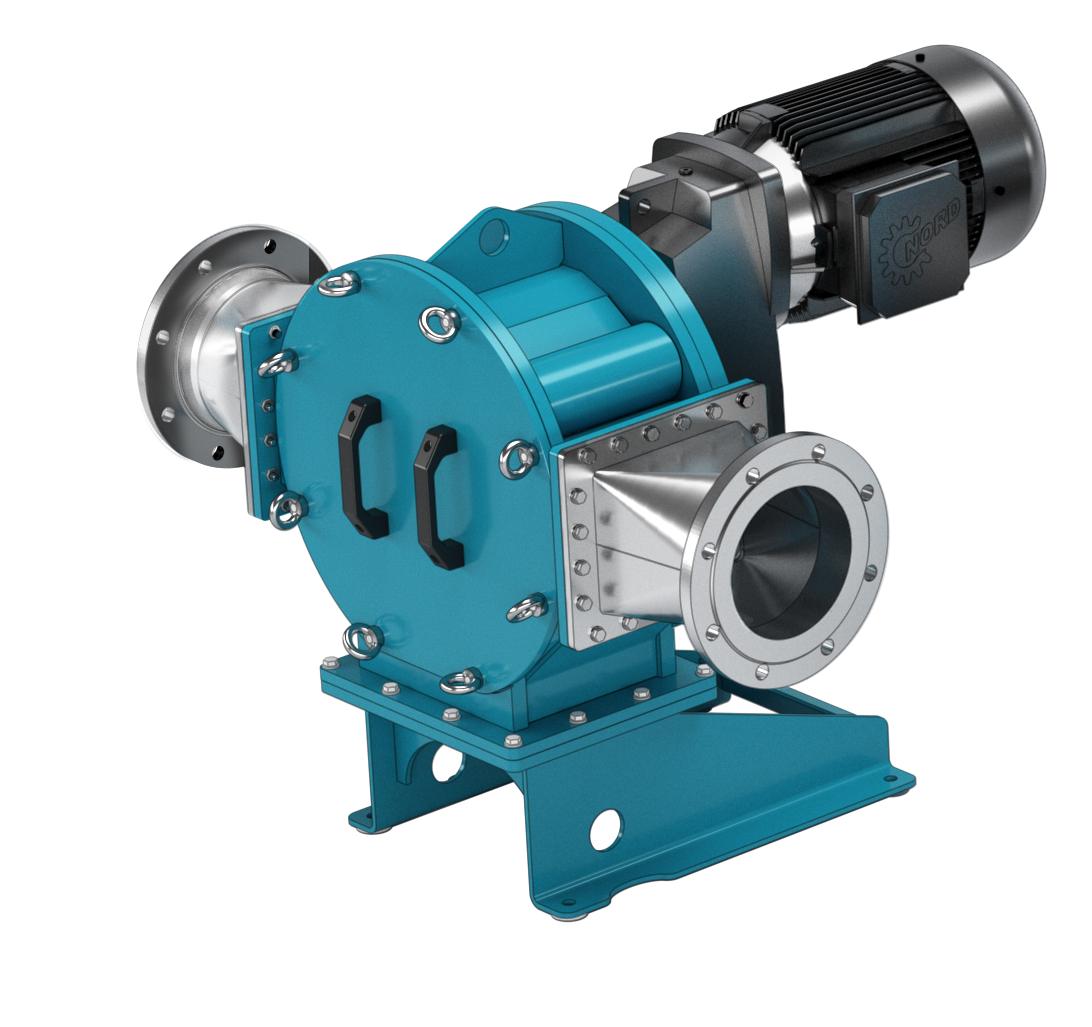

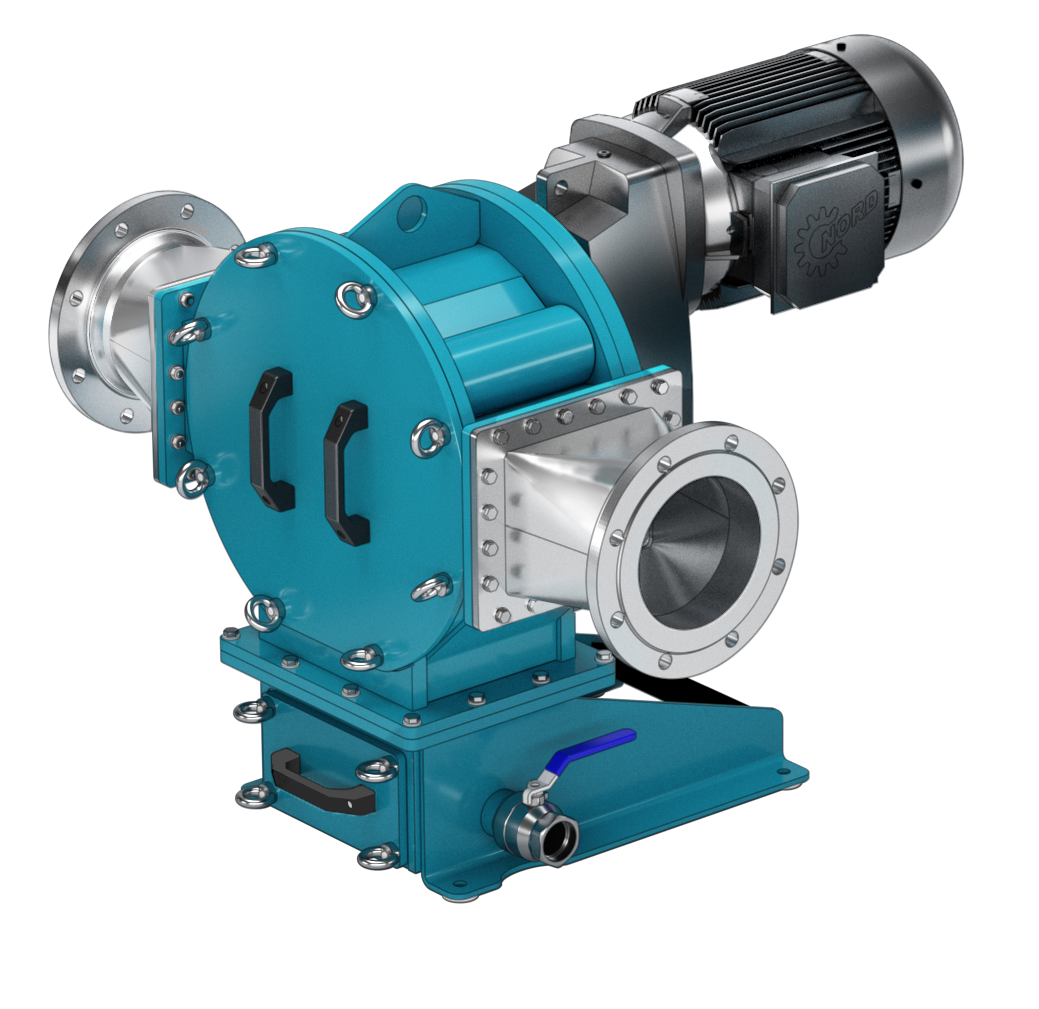

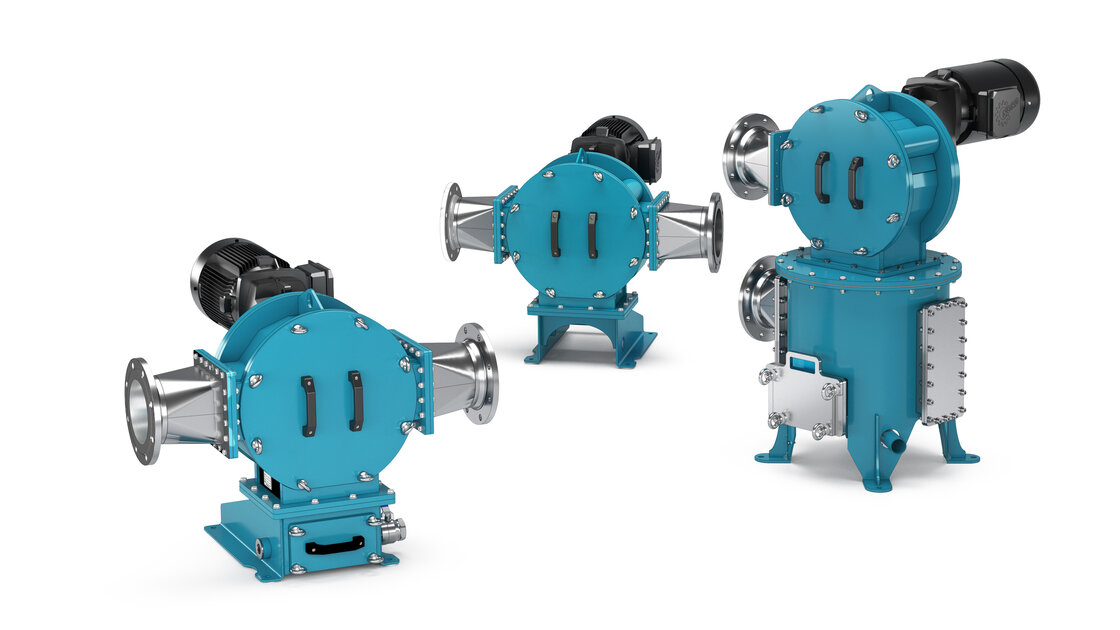

MIP® = Maintenance in Place

Easy maintenance

The quick-release cover and one-sided bearing allow fast direct access to the interior. The blades or counter blades can be turned around or replaced if required in this way.

All the other wear parts can also be replaced fast, easily and economically in a matter of minutes without having to dismantle the Rotorrake.

Case Studies

A vital part in many companies for years

By the late nineties we had completed the Rotorrake design for use in special applications. The macerating concept was convincing. Since then, we have continuously developed the Rotorrake.

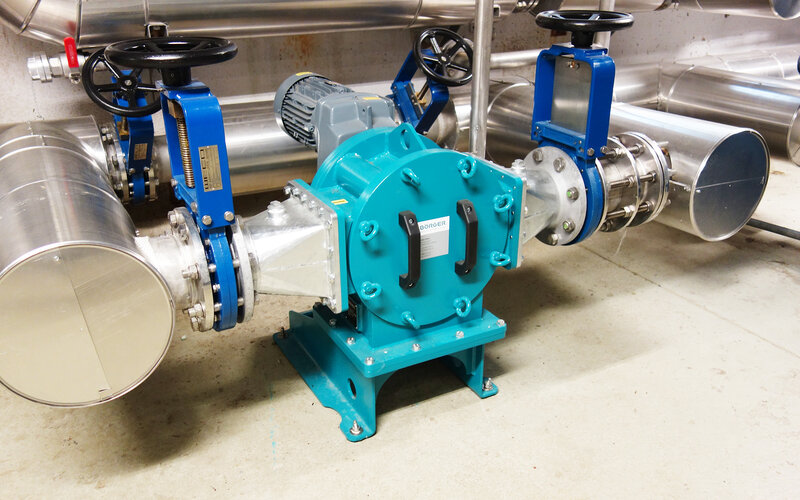

The Rotorrake ensures smooth operation in numerous installations. Here are some examples from practice.

Sludge

An environmental service provider uses a Börger Rotorrake for macerating solids in front of a chamber filter press.

Sludge from grit chambers, pump chambers and rain overflow basins are supplied in the coarse sludge receiving station of the environmental service provider. In the process, the solids-laden sludge passes a screen with a grid size of 100 mm (3.9 inch) and is collected in a receiving basin. The connected Rotorrake macerates the solids still left so that they cannot damage the chamber filter press. The Rotorrake is equipped with an automatic reversing control unit which prevents the solids from stucking.

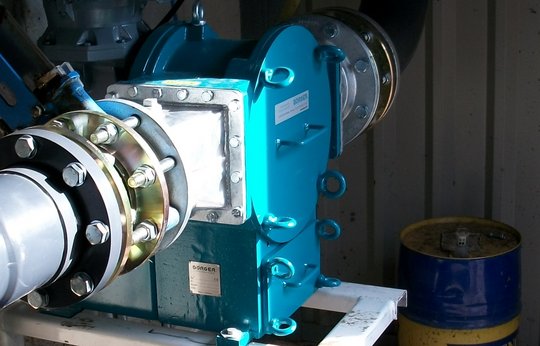

Anaerobic digestion circulation

A wastewater treatment plant was having serious problems with the build-up of clumps in their sludge. The choppers installed were not able to cut up the voluminous clumps in a passable size. This caused constant blockages in the rotary pumps which were supposed to keep the contents of the digestion tower circulating. The operator of the plant decided to try out a Börger Rotorrake. The Rotorrake is a robust chopper in inline design. Blades and counter blades are mounted one after the other on the carrier shaft.

The Rotorrake was tested intensively for a long period of time. During that time, no problems occurred with the Rotorrake and no signs of wear could be detected on the blades or counter blades after the test phase.

Silages

At a two-stage biogas plant, staff were having increasing problems with blockages in an eccentric screw pump due to solids. The pump was installed between the main and secondary fermenter. Various silages are used within the plant (corn, millet, grass, rye) as well as dried chicken manure.

The customer chose a Börger Rotorrake to reduce the solids. The Rotorrake was fitted on the suction side directly in front of the eccentric screw pump.

The operator of the biogas plant is extremely pleased with the chopping yield. No more pump blockages occurred. The Börger Rotorrake's long service life and ease of maintenance continue to impress the customer. He is now considering using additional Börger products for the biogas plant.

Pumping station

A pumping station was experiencing continuous problems when pumping wastewater with coarse solids,cause solids in the pumps which led to subsequent downtime. Solids such as fabric scraps and plastic containers got caught in the pumps and blocked the system.

The pumping station operator then tested various chopping units from different manufacturers. All the choppers tested had difficulties coping with the coarse

solids in the medium. Then they tried the Börger Rotorrake, especially designed for coarse solids. The operator of the pumping station was impressed by the powerful Rotorrake. No downtime from problems with solids has occurred since the Rotorrake has been in operation.

The customer is extremely satisfied with the Börger Rotorrake.