Oil & gas

Heating oil, gasoil, naphtha

For a petrochemical company we built a customized ATEX-compliant mobile pump.

The mobile unit is used for transfer operations and removal of residues from storage tanks in an ATEX zone 1 of the refinery. To be able to use the pump on the partially rough refinery premises, the mobile unit including the drive is mounted on a base frame equipped with fork-lift pockets and crane lugs. A telescopic loader or a crane transports the pump to its respective application site. The pump sucks the fluids through a filter system installed on the mobile unit. The solids are separated. Thanks to the full-metal design of the rotors, the pump can convey virtually all liquids in the refinery plant.

The unit is operated by means of the operating device at the ATEX-compliant pump control unit. The Börger sensor system monitors all safety-oriented functions during operation. If defined pressures or temperatures are exceeded, the pump switches off automatically. The pump is driven by an ATEX-compliant 22.0 kW variable speed motor. The pump speed and the flow rate can be varied continuously between 20 m³/h and 100 m³/h (88 - 440 usgpm/h) by means of a hand wheel. The flow rate can be adjusted to the specific application.

Oil & gas

Tar

A Korean refinery uses an ONIXline rotary lobe pump for conveying hot tar.

To prevent the 256.5 °C hot tar from hardening inside the pump, the ONIXline is equipped with a heater casing and a heater cover. Double-acting Börger mechanical seals protect the gear unit from the pumped medium. The seals are pressurized by a thermosiphon system with cooling. A small circulation pump conveys the cooled barrier fluid through the seals. In addition to providing the barrier effect, this also cools the high-tech seals. Furthermore, the pressurization ensures that the environment is protected against an uncontrolled escape of the hot tar even in case of a seal damage.

Due to the high medium temperature, the O-rings in the pump are made of FFKM. The pump casing is made of stainless steel. In order to prevent tar residues from accumulating in the pump, it is installed vertically. This way, the tar flows out of the pump chamber after the end of the pumping process.

Oil & gas

Refinery pump

For completely discharging the remains of storage tanks in a refinery, our customer sought a transportable self-priming pump. The requirements included: ATEX zone 1, suitable for all types of oil and diesel products, gentle product pumping and high suction capacity.

The solution was the Börger Rotary Lobe Pump as it had already a successful track record in stationary operation. The pump was designed in close cooperation with the operator and corresponds to the high requirements. In particular, priority was placed on the pump control unit with the corresponding monitoring equipment to ensure against dry-run, excess temperatures and pressure, in relation to the local ATEX requirements.

An ATEX variable-speed motor is used as a drive so that the pump output could be continuously adjusted. The chassis and all the components are made to order in-house at Börger to ensure all the requirements of the customer are fully met.

Oil & gas

Tar pit

Highly viscous sludge deposits had to be removed from a tar pit. The problem with the pump systems already in use was the fluctuating viscosity of up to 50,000 mPas due to the temperature and the sometimes very large particles contained in the sludge. Both these factors kept causing the pumps to block.

The solution was the Börger double-pack consisting of a Multicrusher and a Rotary Lobe Pump. The two units are combined on one frame and are operated by individual hydraulic motors. The entire unit is ATEX compliant and is operated immersed in the pit.

Oil & gas

Fuels, oils

A customer from the oil and gas industry was looking for a high-performance long-shaft pump. Due to the extreme weather conditions in winter, the customer wanted a pump which could be installed in a tank two to three meters underground. The customer decided on a long-shaft version of a Börger Rotary Lobe Pump.

The pump is completely underground and fitted with a customized long-shaft coupling between the pump and the drive. Compared with a similarly constructed pump system, the advantage is that the long-shaft coupling was separated from the medium. The pressurized condensate tank is a special feature which required a customized solution for the connections to the assembly plate.

Oil & gas

Ethanol

A major chemicals and mineral oil company runs a mixing plant for E5 and E10 fuels. Here the ethanol is fed in doses into a main flow of petrol. The petrol is delivered in tanker vessels. A pump transports the petrol from the vessel to a storage tank on land. Ethanol is added to the petrol on the way to the storage tank (5% for E5 or 10% for E10). The chemicals and mineral oil company requires a pump for this procedure. The customer uses the Börger Rotary Lobe Pump in an ATEX version.

The ethanol is delivered in tanker vehicles. The Börger Rotary Lobe Pump draws off the ethanol via a storage tank security wall (3 m / 9.8 ft). To ensure an exact dosage even when the petrol pump output varies, the speed of the Börger pump is controlled by frequency converters. A magnetic flow meter (MID) measures the amount of pumped petrol. A corresponding control unit regulates the frequency-dependent speed control. This guarantees an exact mixing ratio of ethanol and petrol.

As the air quality control requirements are applicable here, a pressure gage was installed on the pump quench chamber to shut down the pump if pressure fluctuations occur in the quench chamber. PTFE lip seals were also fitted. This ensures that the pump is permanently technically sealed in accordance with the air quality control requirements.

Oil & gas

Oil-water mixture with shares of wax

An international oil concern was looking for a pump to convey an oil-water mixture in a Gas-To-Liquid Plant (GTL). The oil-water mixture arises as a byproduct in the production process and should be transported to its further use.

The customer decided in favor of a Börger rotary lobe pump. The high quality of the Börger Rotary Lobe Pumps as well as the good experience made with Börger pumps as sump pump convinced the customer.

For the GTL plant, they decided in favor of an execution as submerged pump. This execution is also able to transport the shares of wax, which partly build up in the highly viscous medium.

The customer is very satisfied with the Börger rotary lobe pump. Above all, the possibility to produce the pump according to the customers’ wishes convinced the customer.

Oil & gas

Stripping pump

The importance of tankers as means of transport for liquid substances has increased in recent years. Börger rotary lobe pumps are used for emptying the loading arms. These “stripping pumps”

must convey reliably and very efficiently as the ships are supposed to depart as soon as possible after they have been loaded or unloaded. The Börger rotary lobe pumps are configured individually according to the specific requirements of the media to be conveyed and the filling station. Thanks to the large selection of pump sizes, rotors and materials of the Börger pumps, a suitable pump can be built for each unloading system.

Oil & gas

Refinery pumps

A large refinery uses several Börger rotary lobe pumps for pumping out the collecting basins. The surface water of the refinery, which consists of rainwater, production residues and safety overflows etc., is collected in these basins. The pumps were manufactured according to the API 676 for rotary positive displacement pumps in compliance with the customer's requirements. As the Börger pumps can master the required suction height of 6 m without problems, the pumps could be installed above the collecting basin.

Oil & gas

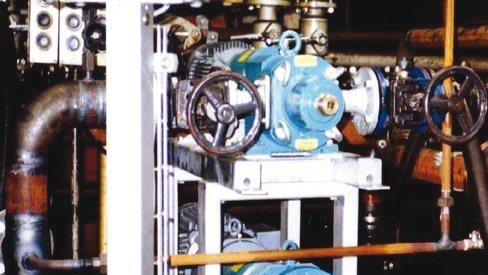

Mobile pump for pigging

A mineral oil company uses two Börger mobile pumps for conveying changing media and for "pigging" the pipelines. For use on the premises, the entire pump units including the pump itself, the drive and the control technology are manufactured in ATEX-compliant design. The mobile units including the drive are mounted on base frames equipped with fork-lift openings. The pumps can be transported to the application site very easily by means of a wheeled loader. The 30 kW three-phase motor is connected to a junction box on the premises by means of an extension cable. The pumps are ready for use straight away and convey up to 100 m³/h (440 usgpm/h) with a pump pressure of up to 8 bar (116 psi).

Oil & gas

Emptying tank wagons

A petrochemical company uses two ONIXline rotary lobe pumps for emptying tank wagons. The pumps with dry-run capability convey methyl tert-butyl ether (MTBE) and 2,2,4-trimethylpentane (isooctane) from the wagons to storage tanks. Due to the high chemical aggressiveness of the pumped media, pump casings were made of stainless steel. The fluids are pumped nearly without pulsation due to the steel rotors with screw profile. All O-rings are made of perfluoroelastomers (FFKM). The self-priming pumps are installed in potentially explosive atmospheres and, therefore, have an ATEX-compliant design.

Oil & gas

Oil sludge

When cleaning up several large oil sludge storage ponds, Börger Rotary Lobe Pumps are used to decontaminate the soil. The sludge and wastewater pumps are subjected to a maximum temperature of 150 °C (302 °C) as processing the soil containing oil is done by rotary kilns. No problem for Börger pumps with FPM coated rotors!

Oil & gas

Heating and diesel fuel

A robust positive displacement pump was required for tank cleaning purposes using “Butterworthing”: Oil is sprayed from nozzles as a coating on the tank walls to prevent corrosion. A Börger Rotary Lobe Pump with diesel motor drive was selected for its robust and easy to maintain design.

Oil & gas

Extinguishing water

A large tank farm for refinery oils was looking for a safe and durable extinguishing water tank. The customer opted for a Börger stainless steel tank. The high quality and the great flexibility of the segmental design were crucial for the decision.

The stainless steel tank was installed in a central location of the tank farm amidst the 13 large-volume tanks (total capacity up to 170,000 m³ (600,349 ft³)). In the case of fire, the tank is accessible by the fire department from all sides. Thanks to the segmental design and the GRP roof that can be installed quickly, the tank could be assembled in a very short time with hardly any restrictions for the tank wagon and truck traffic.