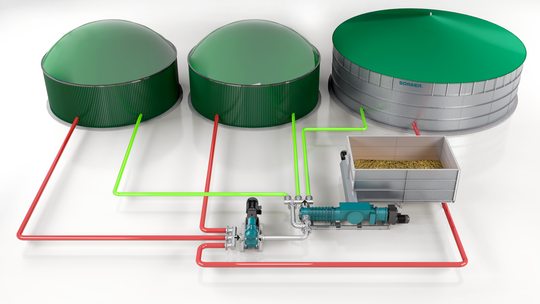

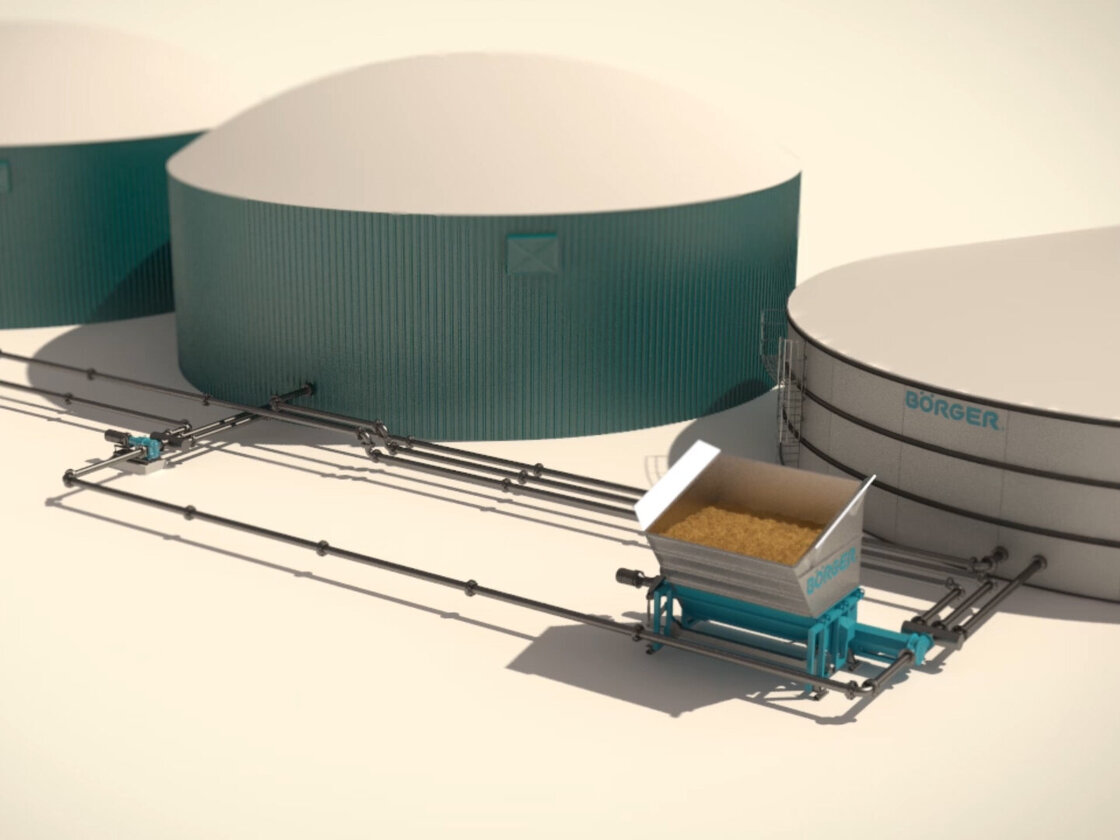

One Powerfeed for any number of tanks

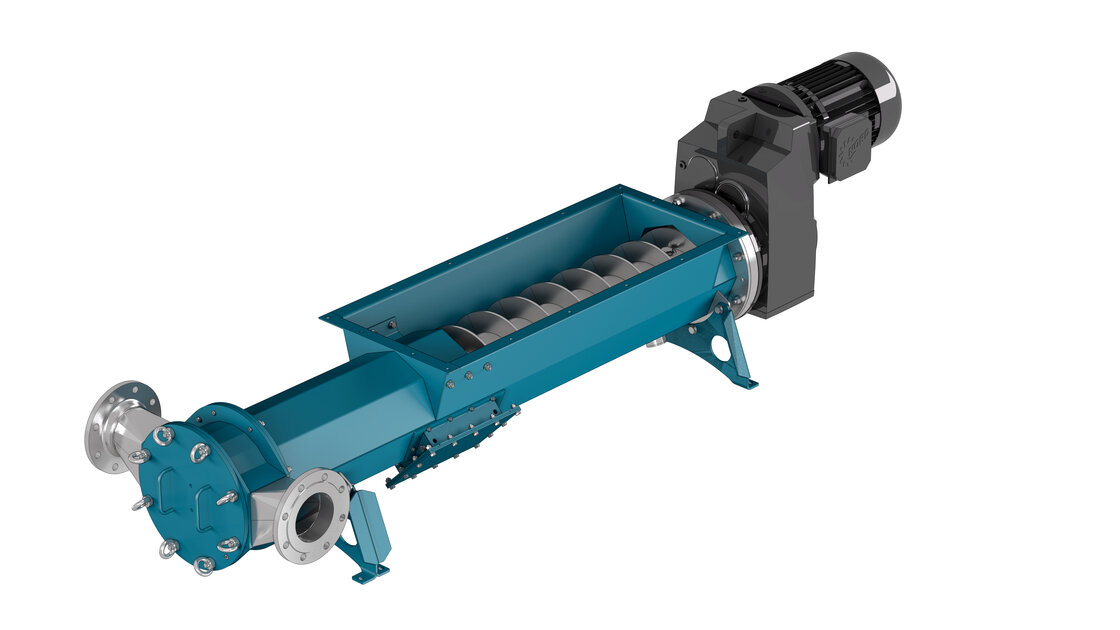

The Powerfeed is integrated at a suitable point in the piping system, so that a powerful biogas pump can extract recirculate from the requested tank. The Börger feeding technology feeds the biomass in doses into the flow pipeline in the fully enclosed system. The recirculate enriched with biomass is conveyed into the requested fermenter.

One Powerfeed for all containers

With a Powerfeed you can feed tanks of any number and of different heights.

The Powerfeed and a high-capacity biogas pump form the central unit of the liquid feeding technology.

The tanks of the biogas plant are connected to the pump via pipe and valve systems, so that the pump can extract recirculate from the requested tank.

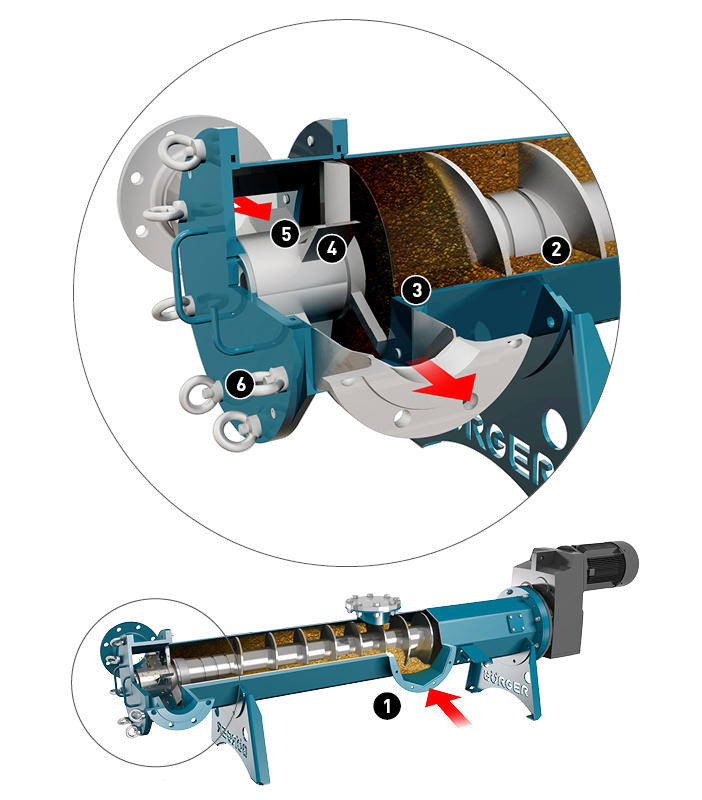

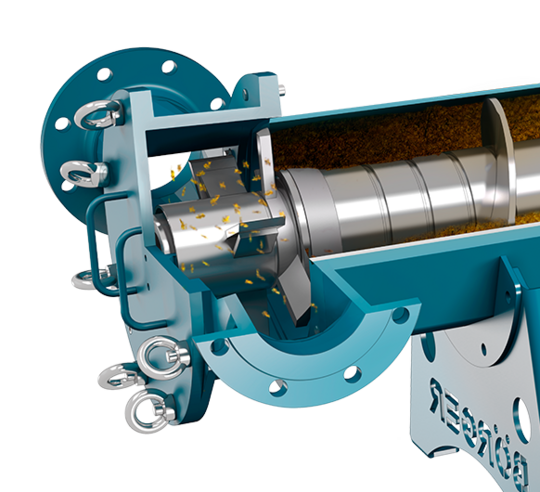

Fine breakdown of the biomass

Inside the Powerfeed, the biomass is compressed and broken down very finely before it is fed into the system.

This concept releases any trapped air from the biomass. The fine biomass particles have a large surface and ensure a higher gas yield. In addition, less floating layers are formed in the tank which results in energy savings due to reduced agitating effort.

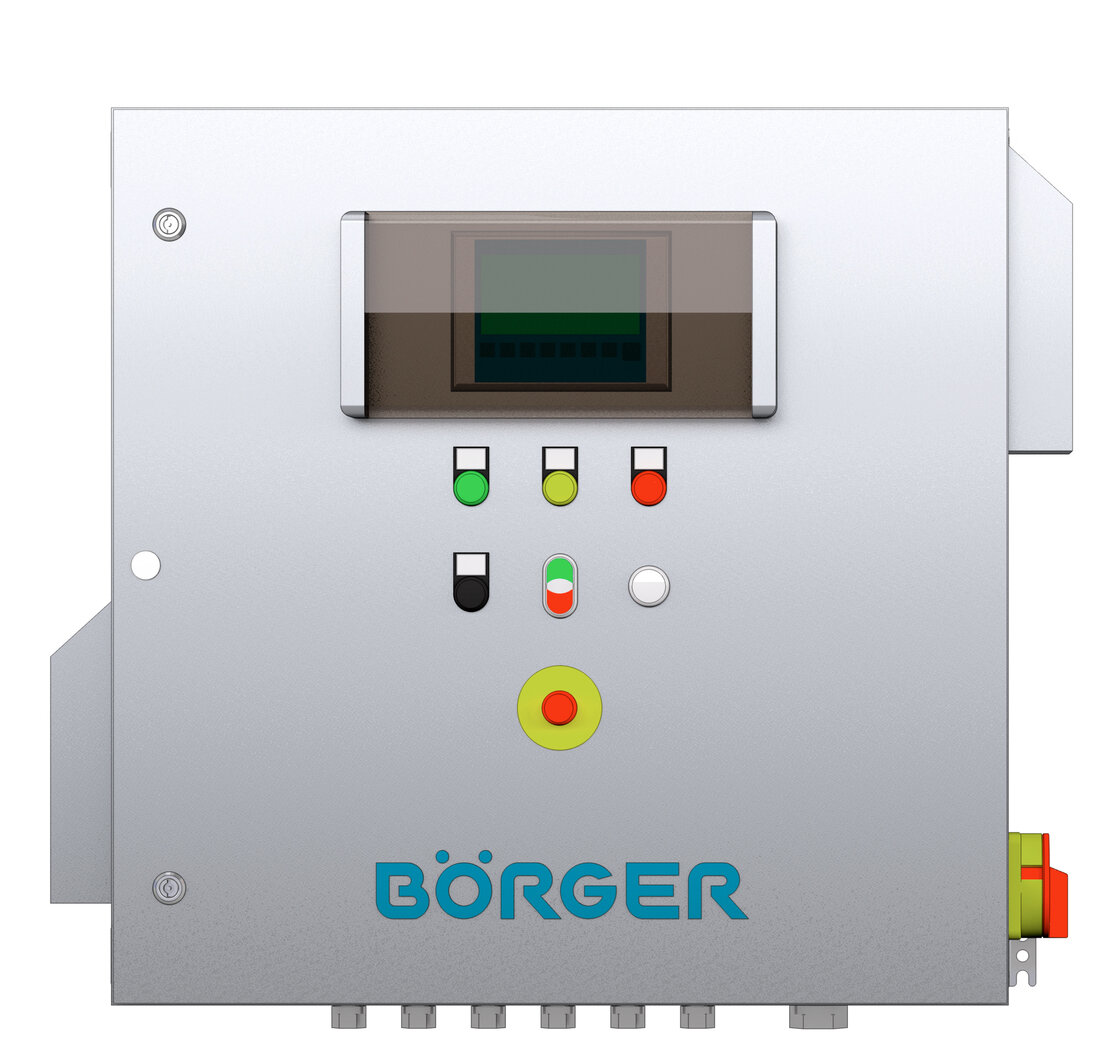

- Ideal coordination of the operation of all components (e.g. Powerfeed, recirculation pump, auger feed, etc.)

- Protection of the entire system (pressure monitoring, dry run protection, function monitoring, etc.)

- Integration via bus system (Profinet, Profibus, etc.)

- Simple entry and user administration via touch display

- External control by operator possible via mobile communication, WLAN, DSL (remote maintenance by Börger is also possible)

- and so on

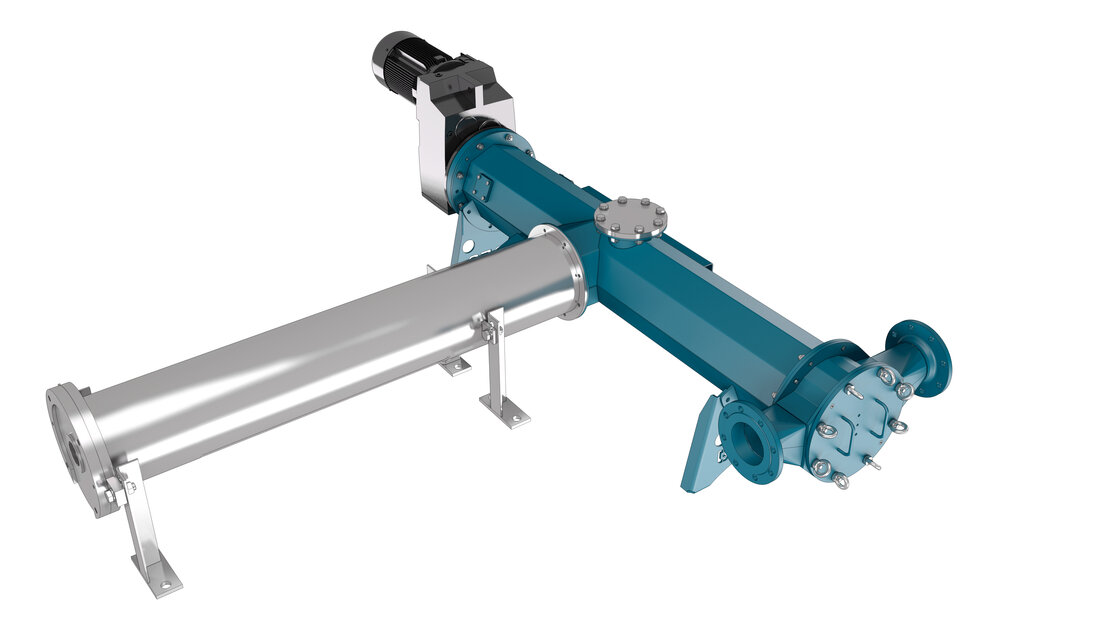

Safe. Flexible. Ease of maintenance.

- Highest level of safety, liquid penetration almost impossible due to the design

- One system for different biomass types

- Can be retrofitted in any biogas plant

- Very easy to maintain

- Everything from a single source – Powerfeed, recirculation pump, control technology and macerator

Combination with storage container

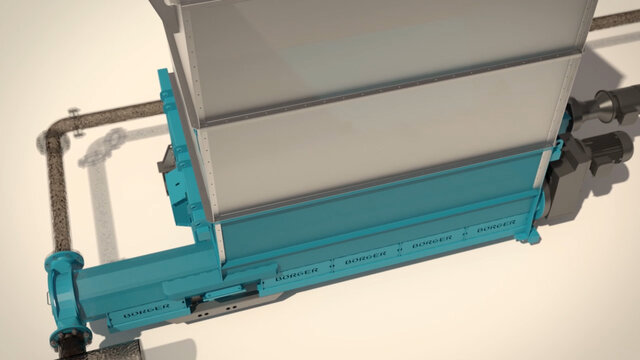

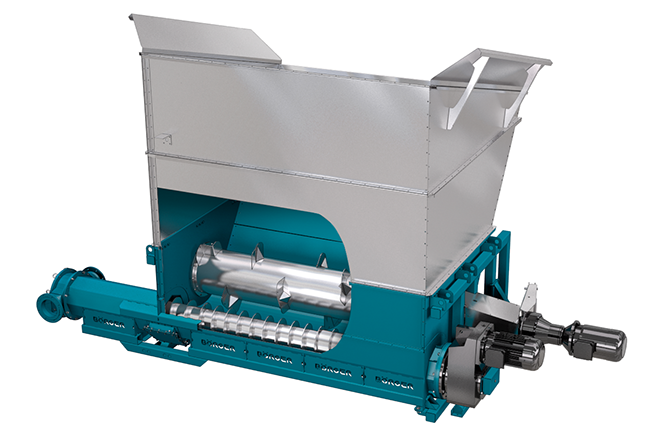

Powerfeed duo

The Powerfeed duo is the complete, worry-free solid feed technology package thanks to a combination between efficient feeding technology, a stainless steel storage container and well-engineered control technology.

The Powerfeed duo can be filled directly from the 3 m wide storage container. The stainless steel storage container has a capacity of 10 t and guarantees continual loading of the Powerfeed.

The paddle drum loosens up the biomass and ensures a uniform infeed of the solids.

A combination with a storage container is also possible. In this case, a weighing device is integrated into the Powerfeed duo. There is no weighing at the storage container.

Solids feeding

An agricultural holding was looking for reliable feeding technology for transferring corn silage to a biogas plant.

After scrutinizing the feeding technology of various providers, the biogas plant operator chose the Börger Powerfeed 400. The customer was impressed with the renowned high quality of the Börger products, particularly the entirely closed system, the uncomplicated, easy controls and the Powerfeed design which prevents gas from escaping.

The customer chose a Börger Biogas Rotary Lobe Pump to convey the recirculate. The customer is extremely pleased with the Börger Biogas Rotary Lobe Pump and the Powerfeed 400. The long service life and easy handling ensure efficient operation of the biogas plant.

Optimization of biogas plants

A plant construction company specializing in optimizing biogas plants was looking for feeding technology for a 950 kW plant. It was essential that the technology would be odorless and free of gas.

The plant construction company opted for a Börger Powerfeed. They were impressed with the Powerfeed's innovative and sophisticated technology and particularly with the high efficiency of Börger feeding technology. The renewable resources are worn down due to the positioning and type of the press unit in the Powerfeed as well as the design of blade and dosing unit. Through this they obtain a larger surface area. All the trapped air is released by compressing the solids into clumps. Less floating layers form in the tank.

By specifically dosing the solids, the agitating in the tank could be significantly reduced. The plant construction company and the plant operator are extremely satisfied with the Börger Powerfeed.

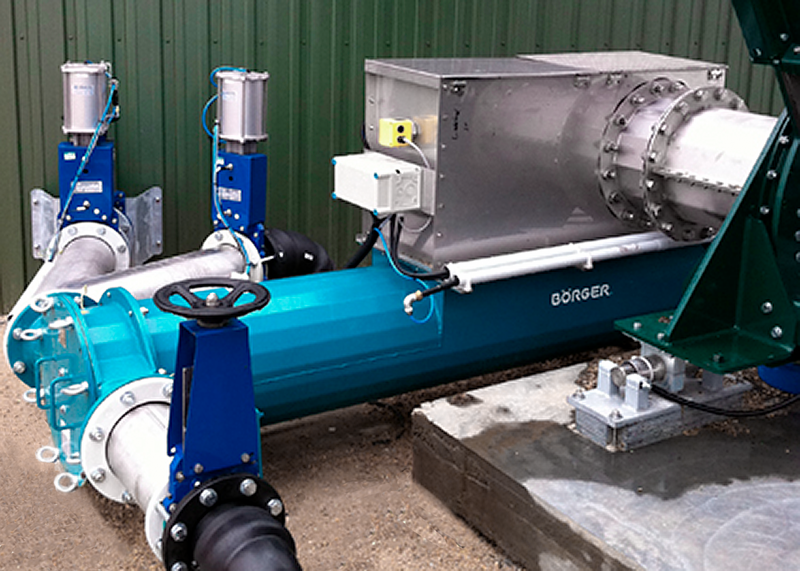

Feeding technology - filling by wheeled loader

A biogas plant operator was looking for reliable liquid feeding technology to feed solids into their secondary fermenter. The biogas plant was upgraded to include an additional CHP. The feeding technology was also required to load the fermenter and replace the plug screw currently used. After finding out about state-of-the-art technology from various manufacturers, the biogas plant operator decided on Börger's Powerfeed duo. In addition to the renowned optimum reliability of Börger products, the customer was also particularly impressed by the Powerfeed duo's well-engineered, integrated design concept.

The storage tank supplied with the Powerfeed duo can be filled directly using a wheeled loader. Constant loading of the Powerfeed is guaranteed thanks to the 10 t storage capacity. The Powerfeed and a high-capacity biogas pump form the central unit of the liquid feeding technology. The unit is very easy to operate using an operating device at the control cabinet. A control unit ensures trouble-free system operation. Different sensors constantly monitor the fill level in the Powerfeed. The data readings are transmitted to the control unit. The Powerfeed switches off automatically when the pre-set limits are exceeded.

The customer is very satisfied with the Powerfeed duo. He was won over by its optimum reliability, easy operation and efficient biomass feed.

Replacement for solids dosing feeder

An operator of a biogas plant has been using a solids dosing feeder for feeding the biomass into the fermenter for several years. The operator was looking for an alternative feeding technology due to the extension of the biogas plant and the very high agitating effort.

The operator opted for a Börger Powerfeed connect. The liquid feeding technology can be used for feeding tanks of any number. In addition, they were able to use the existing technology to a large extent.

The biogas plant operator is very satisfied with the Powerfeed connect. The customer was particularly impressed by the ease of operation, the trouble-free operation and the long service life. In addition, the agitating effort in the tanks has been significantly reduced and the gas yield has been increased.