Effective substrate mixing

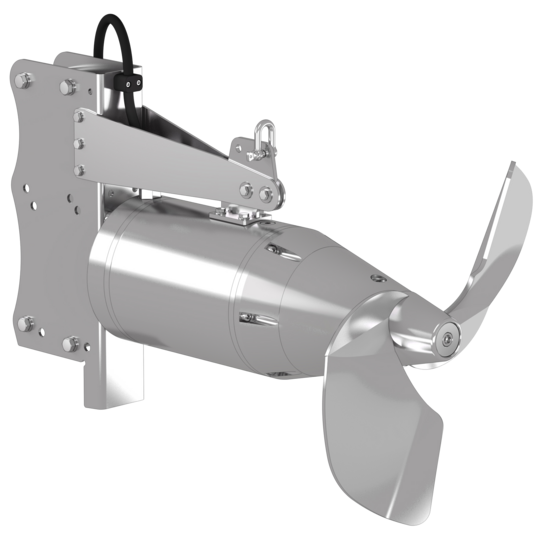

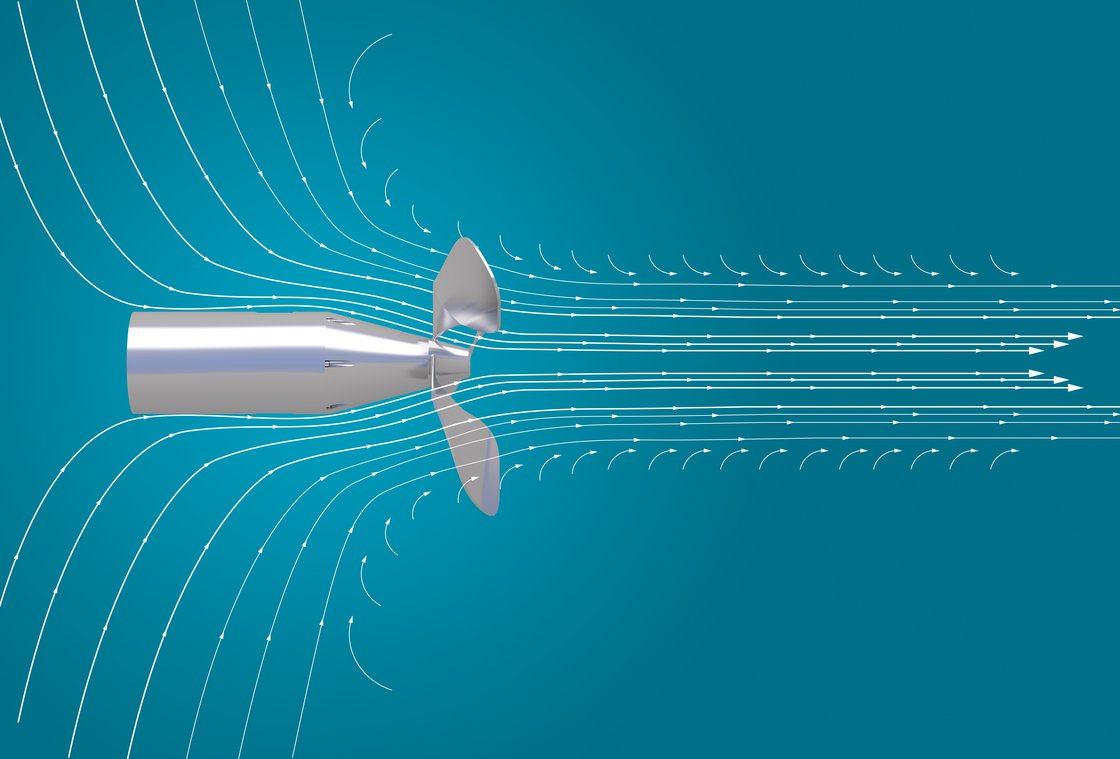

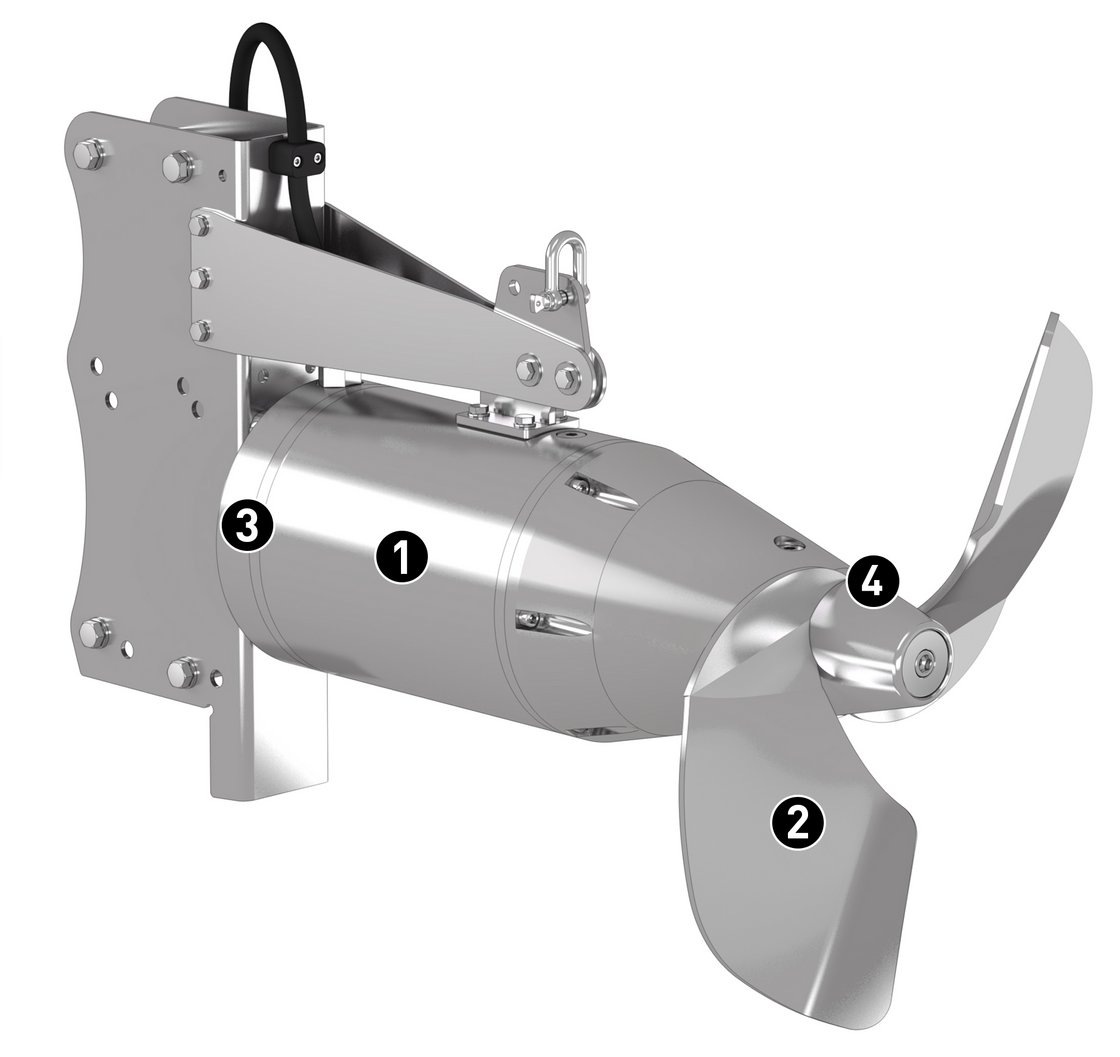

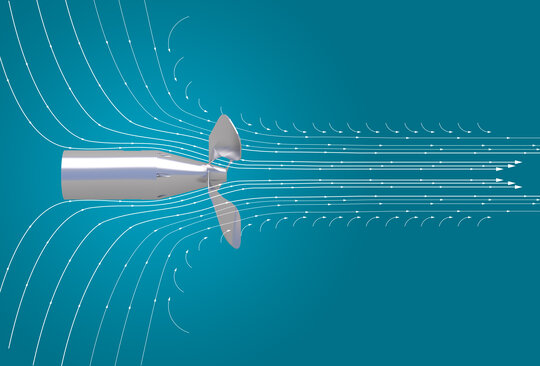

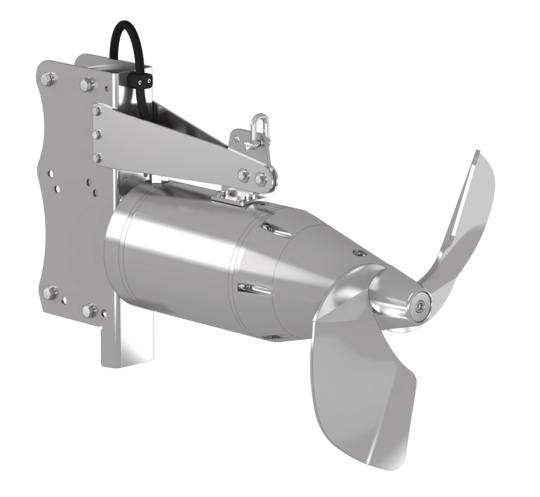

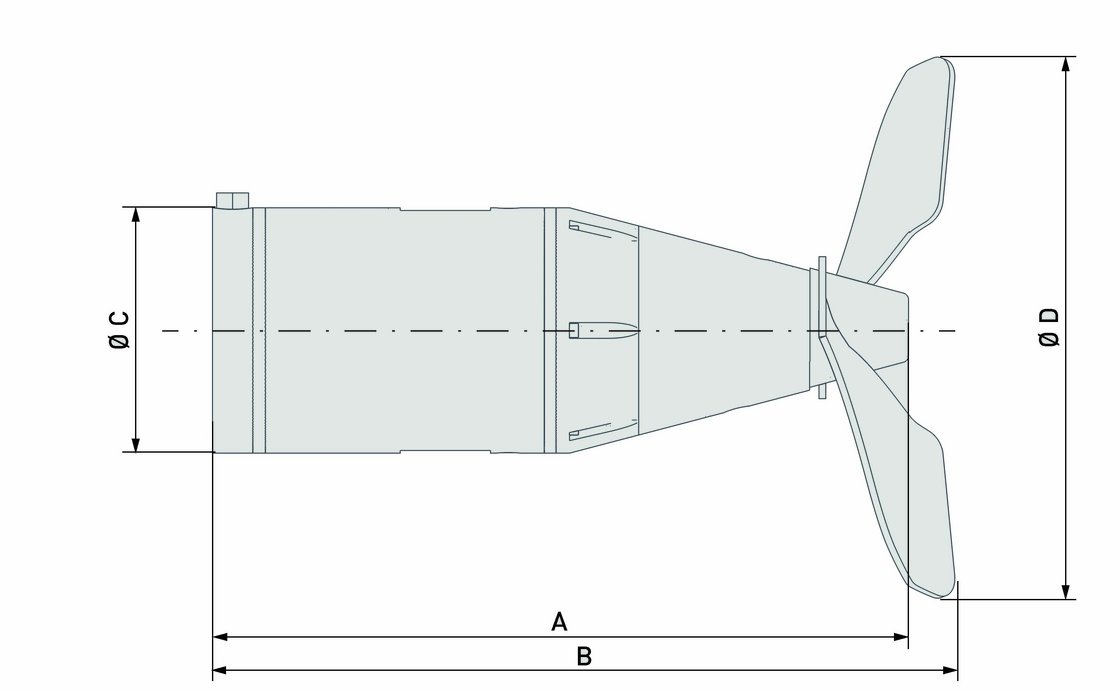

With its aerodynamic blades, the Börger B-MX is installed in a tank filled with liquid or in a liquid manure channel. The rotation of the mixer blades ensures that the fluid is circulated, including the solids it contains. Thick floating layers and heavy sediment are stirred.

The ultra-slim design and smooth surface of the whole submersible mixer allows liquid to flow to the displacement blades without creating turbulence. This guarantees high efficiency.

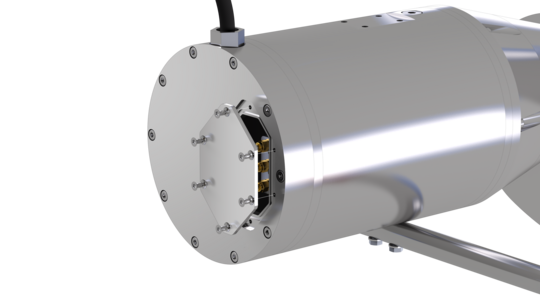

Highest level of safety thanks to mechanical seal and intermediate chamber

The system is sealed by a high-quality mechanical seal. A large-volume quench chamber ensures the highest degree of operational safety.

Optionally, an electronic leakage detector is installed in the intermediate chamber to recognize leaks at an early stage and to avoid consequential damage.

Options

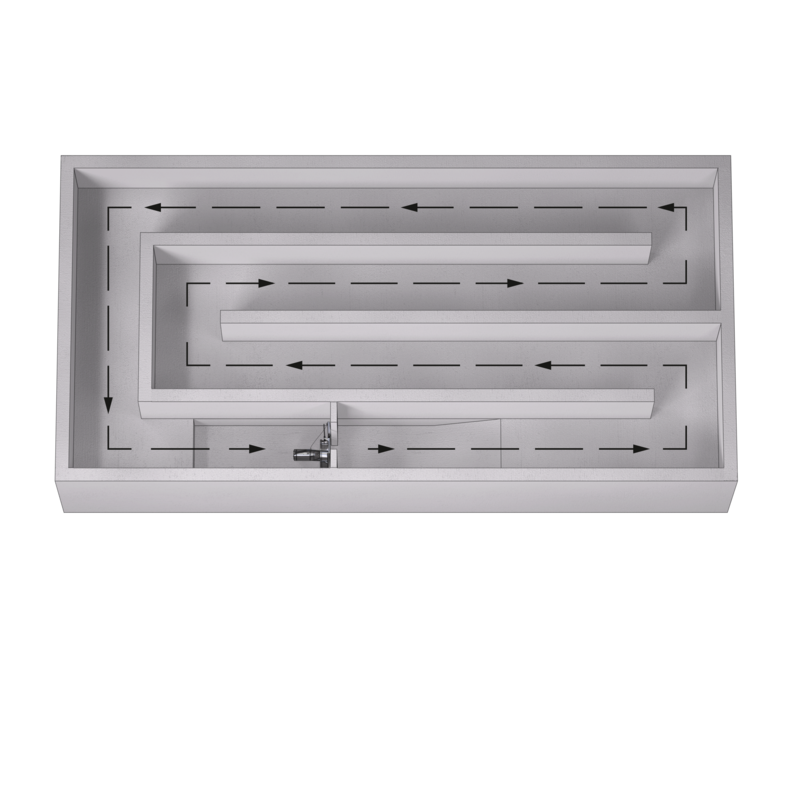

Tank circulation

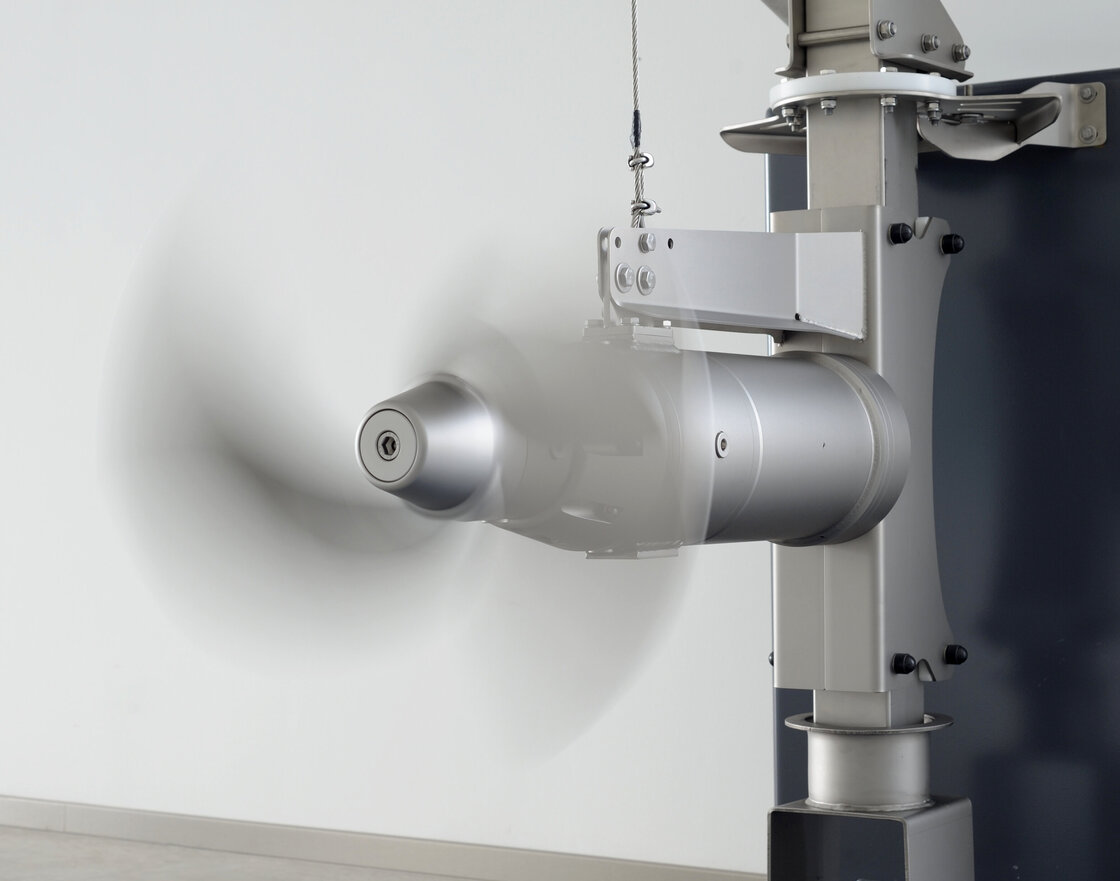

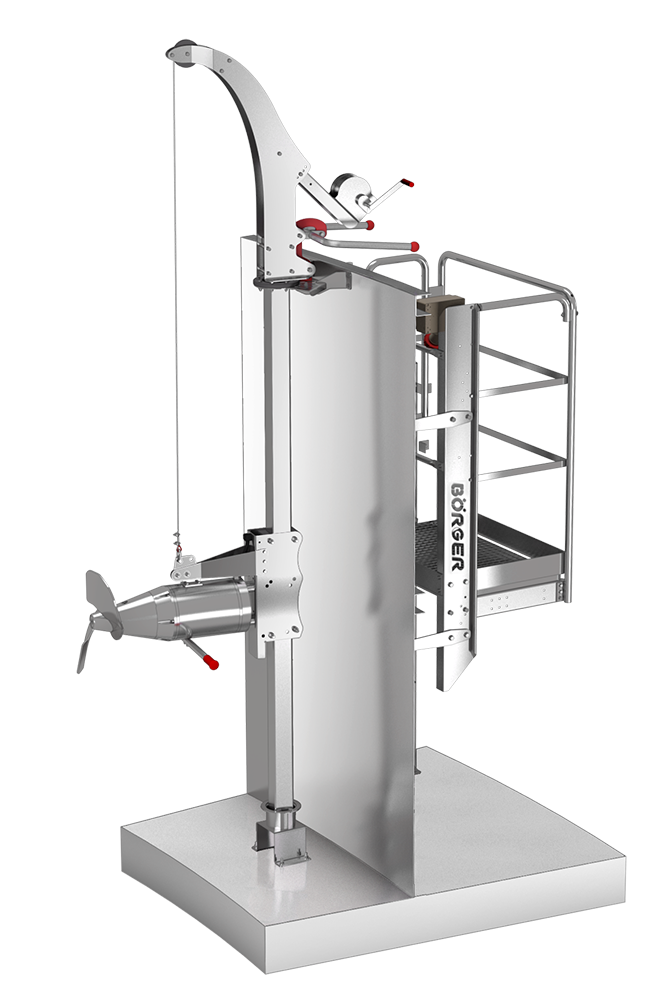

The B-MX can be used for circulation in elevated or underground tanks.

It is connected to the guide rail by means of the guide carriage. The guide rail guides the mixer. Attaching the mixer to the tank wall is not necessary.

The adjustment unit can be used to change the height and the lateral position of the mixer. The B-MX can always be adjusted optimally with changing fill levels, thus ensuring the best possible homogenization of your stored liquid.

At an elevated tank you can reach the adjustment unit very easily via the work platform. From here, you can look into the tank. On request, we manufacture the working platform exactly to your specification.

| Type | B-MX 9 | B-MX 13 | B-MX 18 | B-MX 22 |

|---|---|---|---|---|

| Output [kW] | 9 | 13 | 18 | 22 |

| Output [HP] | 12.1 | 17.4 | 24.1 | 29.5 |

| Output [m³/h] | 3,780 | 5,020 | 6,860 | 8,640 |

| Output [gpm] | 16,643 | 22,102 | 30,204 | 38,041 |

| Nominal current [A] [water] | 19 | 24.5 | 35 | 41 |

| Rotational speed [rpm] | 346 | 346 | 346 | 346 |

| Propeller diameter [mm] | 650 | 650 | 750 | 750 |

| Propeller diameter [inches] | 25.6 | 25.6 | 29.5 | 29.5 |

| Weight [kg] mixer | 170 | 180 | 220 | 240 |

| Weight [lbs] mixer | 375 | 397 | 485 | 529 |

| Weight [kg] circulation frame | 50 | 50 | 57 | 57 |

| Weight [lbs] circulation frame | 110 | 110 | 126 | 126 |

| Weight [kg] guide rail | 25 | 25 | 25 | 25 |

| Weight [lbs] guide rail | 55 | 55 | 55 | 55 |

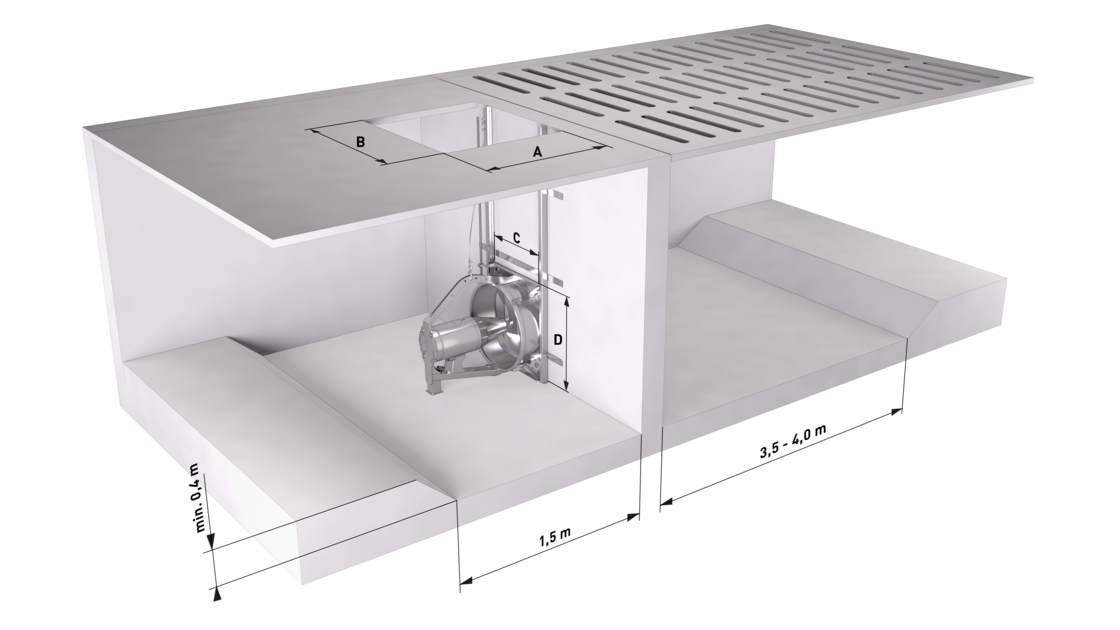

| Installation opening A x B [mm] | 1,000 x 850 | 1,000 x 850 | 1,100 x 950 | 1,100 x 950 |

| Installation opening A x B [inches] | 39.4 x 33.5 | 39.4 x 33.5 | 43.3 x 37.4 | 43.3 x 37.4 |

| Opening in transverse wall C x D [mm] | 750 x 800 | 750 x 800 | 850 x 850 | 850 x 850 |

| Opening in transverse wall C x D [inches] | 29.5 x 31.5 | 29.5 x 31.5 | 33.5 x 33.5 | 33.5 x 33.5 |

IMPORTANT: Opening must be flush with the base.

Circulation system

In a circulation system a cattle farmer used 3 PTO mixers which were driven externally by the PTO shaft of his tractor.

As part of a barn enlargement the cattle farmer now uses three Börger submersible mixers B-MX. The submersible mixers completely made of stainless steel could be attached to the existing guide rails of the replaced PTO mixers.

Propellers with a diameter of 400 mm (15.7 inch) were selected due to the low space. The submersible mixers are driven by a 9 kW electric motor.