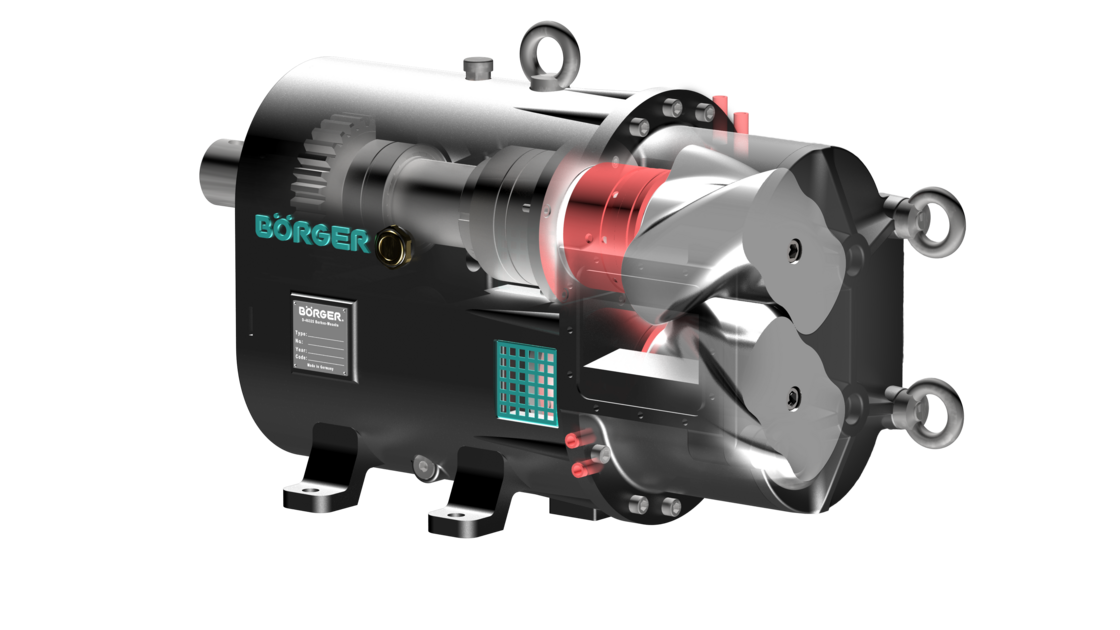

The ONIXline rotary lobe pumps were developed by means of the most advanced flow simulation technology and experience in rotary lobe pump construction from several decades.

The pump stands for gentle, practically pulsation-free pumping with maximized efficiency. The large sealing chamber makes the use of different sealing systems possible.

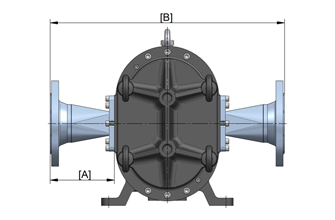

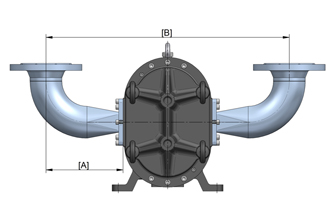

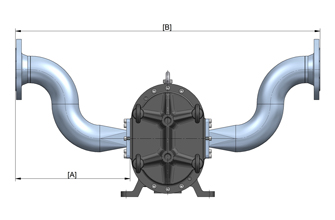

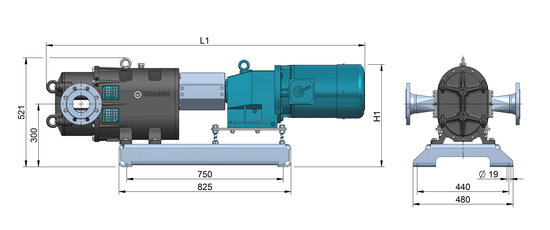

Construction

Perfection down to the last detail

At the heart of the pump are the completely new rotors. They were developed by means of the most advanced flow simulation technology and experience in rotary lobe pump construction from several decades. The rotors ensure gentle, practically pulsation-free pumping with maximized efficiency.

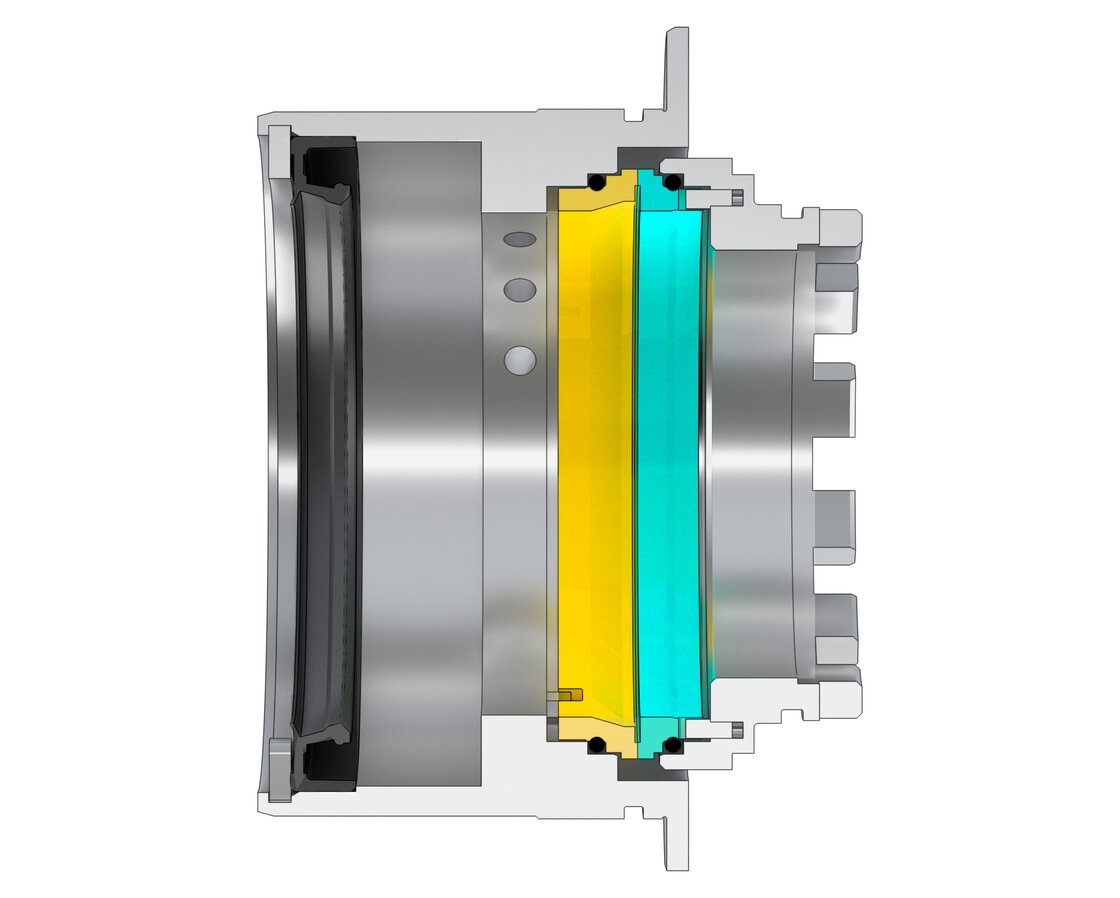

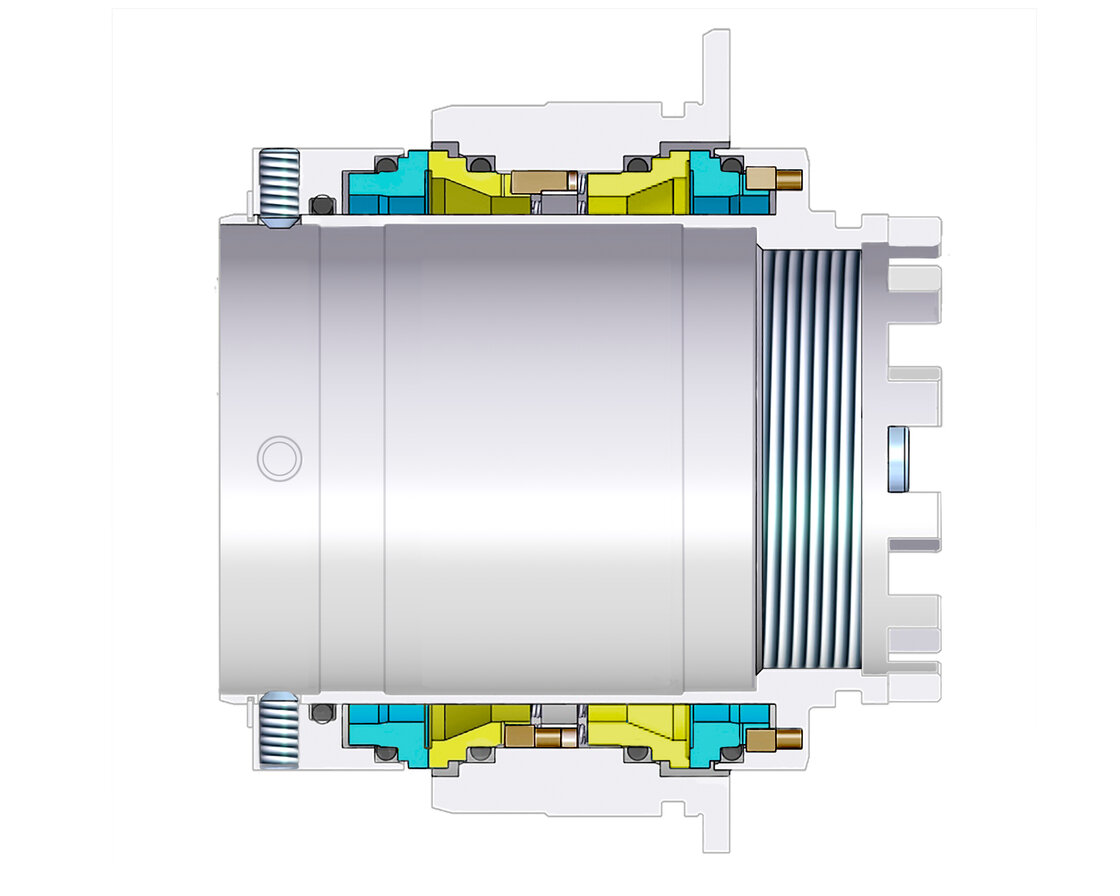

The ONIXline Rotary Lobe Pump has a very large seal chamber and provides space for almost any sealing system. This way, there is always a sealing system which is perfectly suited to the pumped medium. Connections for circulation lines are integrated in the pump casing.

Börger offers different types of seals which are selected for the specific applications. Know-how gained from several decades of pump and mechanical seal construction has been used to build each Börger seal. Several supply systems for the seals can be selected.

THE BÖRGER SEALS (selection):

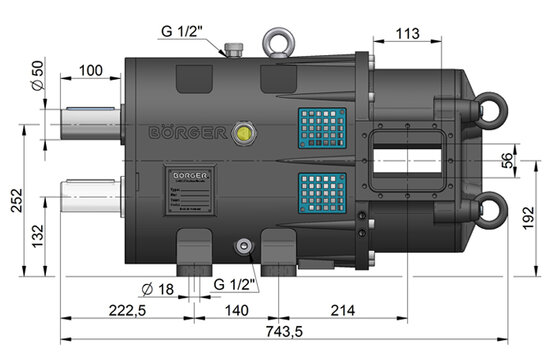

The ONIXline rotary lobe pump has been especially designed for pumping very demanding media. Due to the very large speed range of 1 to 800 rpm and a pressure stability up to 230 psi, the ONIXline pump can be used where other pumps reach their limits.

Pump performance curves provide information about the efficiency of a pump. The flow rates of Börger rotary lobe pumps remain virtually constant even in case of increasing pressures.

Starch

A manufacturer of magazine paper uses a Börger ONIXline rotary lobe pump for conveying starch.

The pump conveys the starch from the coating kitchen into the coater. The starch increases the paper’s strength. The ONIXline pump is equipped with pressurized, double-acting mechanical seals. Stainless steel rotors with screw profile convey the very abrasive starch with low pulsation.

Heat-sealing lacquer

A manufacturer of specialty chemicals uses ONIXline rotary lobe pumps for conveying a polymer solution (heat-sealing lacquer).

The pumps made of stainless steel convey the viscous final product from the production plant through a filtration system and to the storage tank. The medium has a temperature of 176 °F (80 °C) and a viscosity of 6,500 to 8,000 mPas. Due to the viscosity, pressures of up to 160 psi are produced.

The pumps are permanently technically tight pursuant to TA Luft and have an ATEX-compliant design for installation in a potentially explosive atmosphere. The mechanical seals in cartridge design are pressurized via a pressure vessel. The stainless steel rotors with screw profile convey the heat-sealing lacquer nearly without pulsation and very reliably.

Fatty acid

A company producing lubricants uses an ONIXline rotary lobe pump for conveying fatty acid.

The stainless steel pump is equipped with stainless steel rotors with screw profile. It conveys the fatty acid from the delivery tanker trucks into the storage tanks of the production facility. Since the fatty acid hardens at temperatures below 122 °F (50 °C), the tanker trucks and all pipes are heated.

To prevent the medium from hardening inside the pump, the ONIXline is equipped with a heater casing and a heater cover. This way, the pumped medium can be kept at the required temperature also during the pumping process. The casing and cover are heated by hot water. As an alternative, thermal oil or hot steam can be used.

Tar

A Korean refinery uses an ONIXline rotary lobe pump for conveying hot tar.

To prevent the 4,649 °F (256.5 °C) hot tar from hardening inside the pump, the ONIXline is equipped with a heater casing and a heater cover. Double-acting Börger mechanical seals protect the gear unit from the pumped medium. The seals are pressurized by a thermosyphon system with cooling. A small circulation pump conveys the cooled barrier fluid through the seals. In addition to providing the barrier effect, this also cools the high-tech seals. Furthermore, the pressurization ensures that the environment is protected against an uncontrolled escape of the hot tar even in case of a seal damage.

Due to the high medium temperature, the O-rings in the pump are made of FFKM. The pump casing is made of stainless steel. In order to prevent tar residues from accumulating in the pump, it is installed vertically. This way, the tar flows out of the pump chamber after the end of the pumping process.

Secondary fuels

A South Korean cement plant uses an ONIXline Rotary Lobe Pump for charging the furnaces with secondary fuels.

Due to the high chemical stress caused by the secondary fuels containing solvents, the pump casing of the ONIXline pump is made of stainless steel. A replaceable casing lining protects the pump casing from wear caused by abrasive components in the pumped media with high solids content. The stainless steel rotors with screw profile convey the fuels very evenly and with low pulsation.

The service life is significantly better than that of the gear pump used before. In addition, maintenance work requires a lot less time and effort.