Effective operation

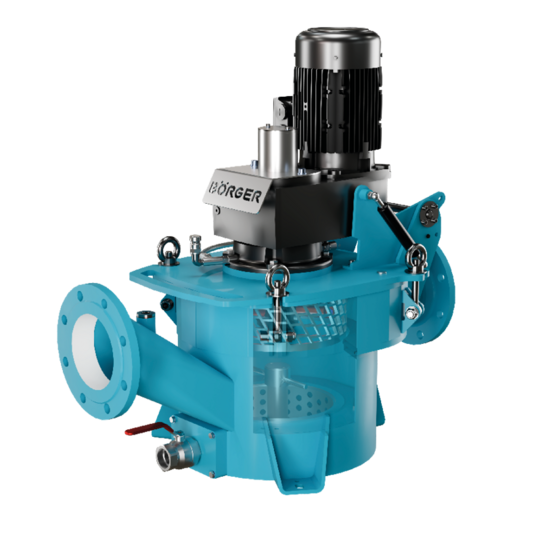

With the OrbitGrinder, we have completely rethought the principle of perforated disk shredding.

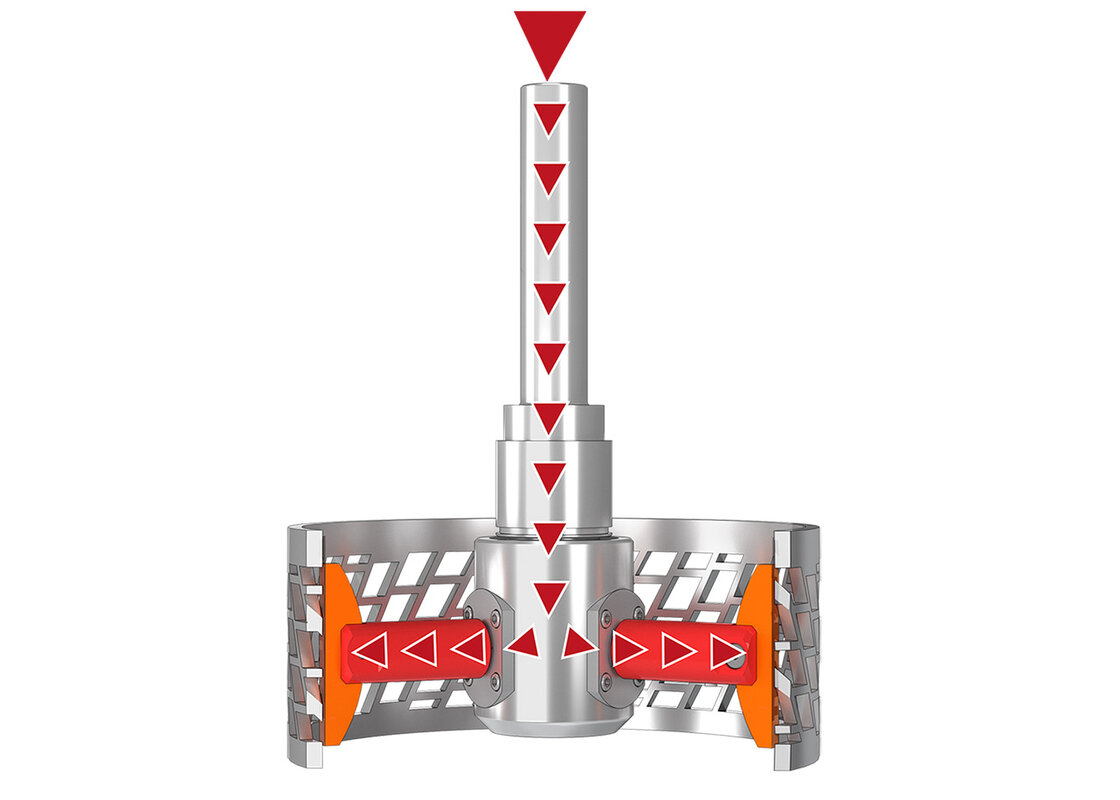

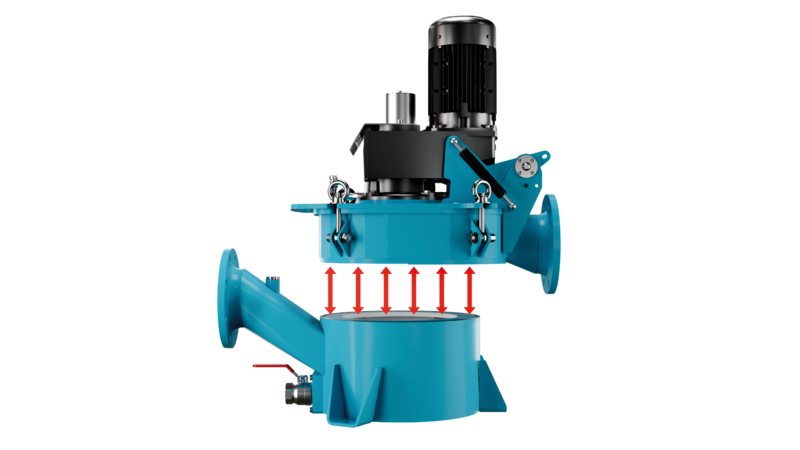

At the heart of the macerator are cutting blades arranged in a star shape, which rotate inside a round cutting basket. This new technology enables us to achieve a consistently good and even cutting quality at all points in the cutting basket.

Automatic blade adjustment

The contact pressure can be readjusted individually for each blade. This is done completely automatically by a central adjustment unit which applies a constant pressure on the blades.

The blades lie perfectly on the surface, the cutting force remains constantly high for each blade and the cutting result is consistently good.

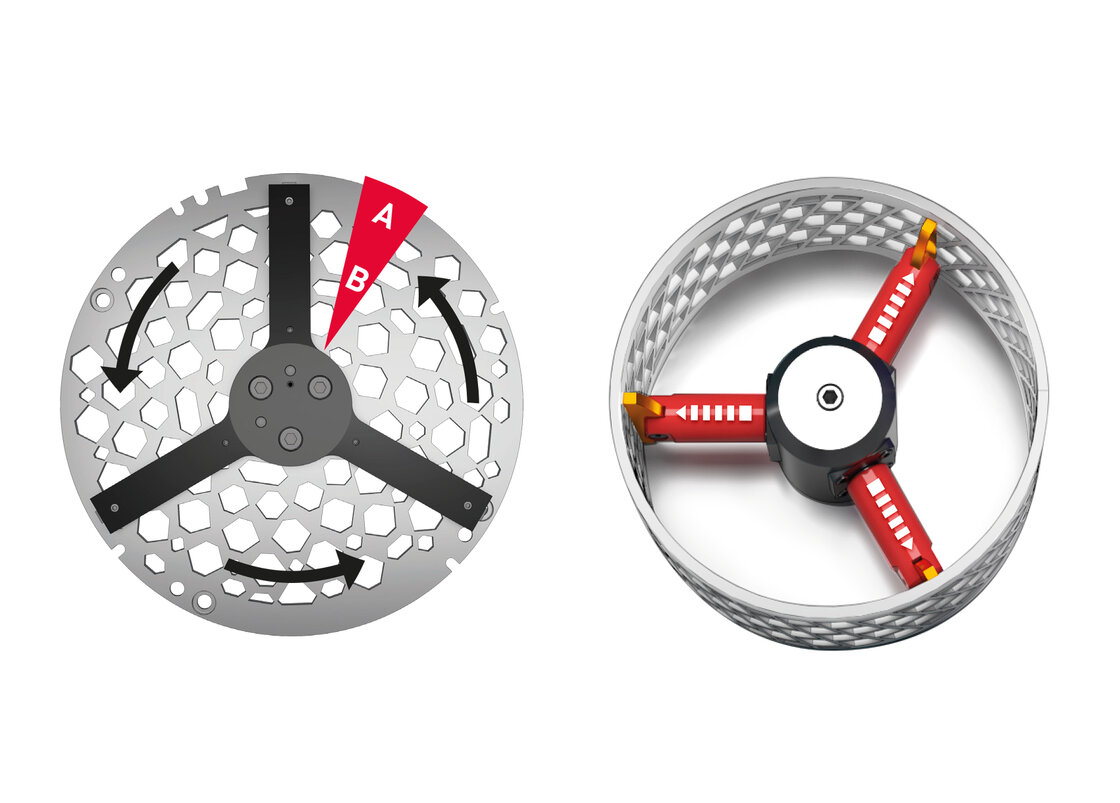

Ideal cutting speed

Conventional perforated disk macerators (on the left) operate with a cutting plate over which blades rotate. At the outer edge of the cutting plate [A] the circumferential speed is significantly higher than in the center [B]. This results in excessive wear.

The OrbitGrinder (on the right) has identical cutting speeds at every point of its blades. This ensures excellent macerating results and unprecedented service lives.

Customize individually

Cutting baskets with different hole patterns can be used in the OrbitGrinder. In combination with the flow speed and the rotational speed, you can adjust the maceration degree.

The conical geometry of the cutting holes improves the flow of particles. The hole edges of the cutting basket are constantly sharpened by the cutting blades. They remain sharp and guarantee a consistently excellent cutting result.

MIP® = Maintenance in Place

Easy maintenance within a few minutes

The OrbitGrinder is designed according to the Maintenance in Place (MIP®) principle. All maintenance work can be done easily and quickly at the installation site of the device. It is not necessary to remove the OrbitGrinder from the pipeline.

Only the quick-release cover, which is supported by a gas strut, is folded upwards. All wear parts can be accessed easily and replaced within a few minutes. The debris collector is removed and emptied. Any escape of liquid during maintenance work is prevented.

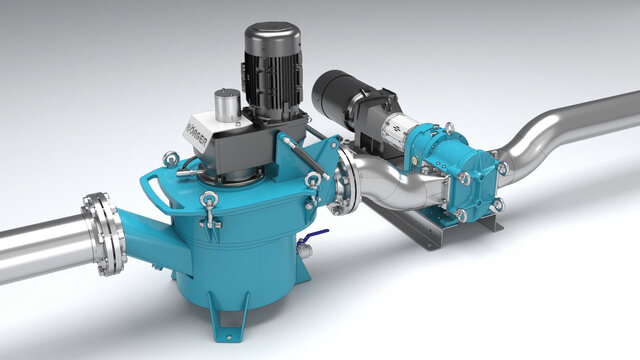

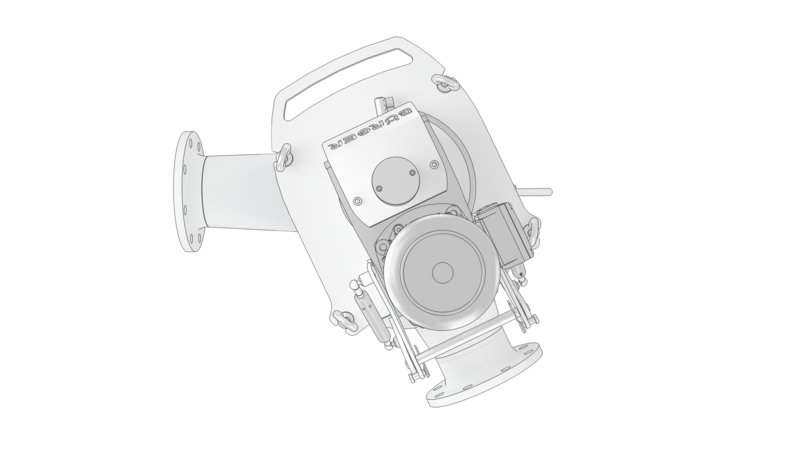

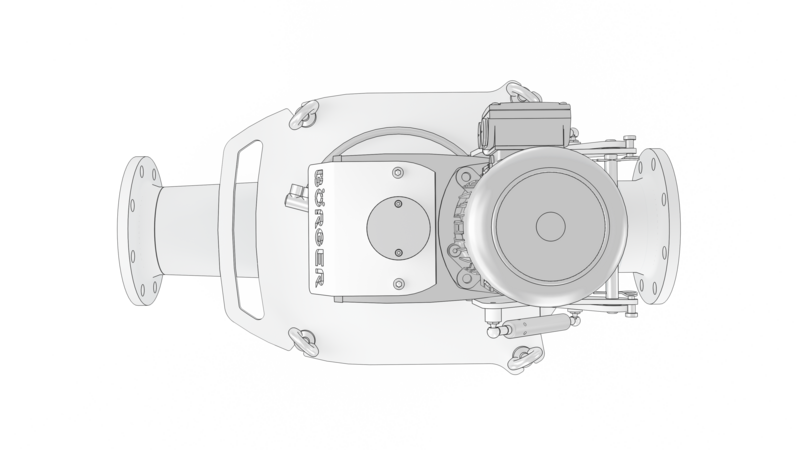

Flexible integration in your system

The OrbitGrinder can be integrated perfectly in almost any existing system.

The in- and outlet can be positioned to each other at different angles. The top and bottom parts of the OrbitGrinder are connected by screws. In order to change the angle between the inlet and outlet, the bottom part of the Orbit Grinder is disconnected from the top part and screwed on again in the desired position.

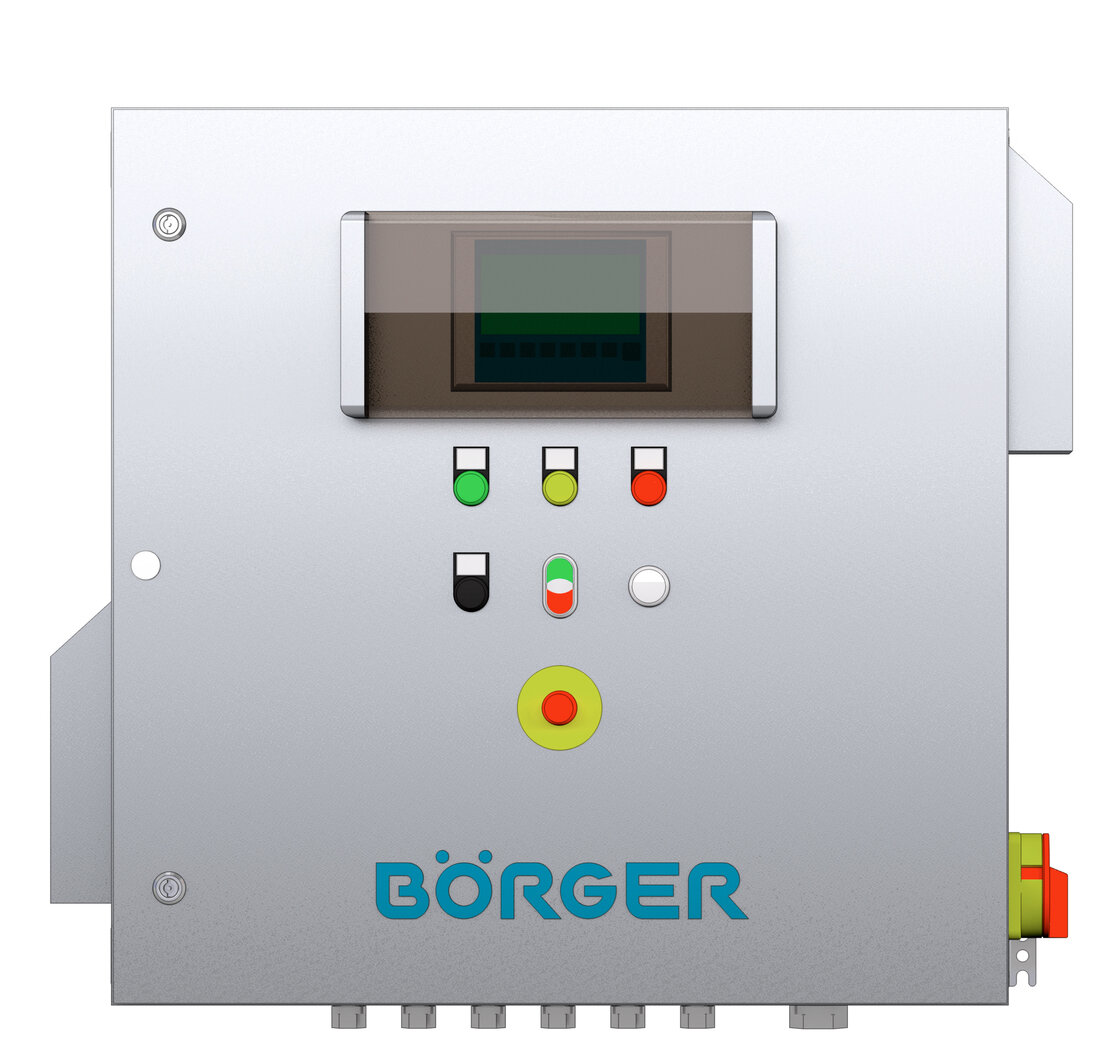

- Highest degree of operational safety due to reversing control (load- and/or time-dependent reversing)

- Easily adjustable reversing parameters

- External control by operator possible via smartphone, WLAN, DSL (remote maintenance by Börger is also possible)

- Production data acquisition

- Simple entry and user administration via touch display

- Module or control cabinet solutions

- Integration via bus system (Profinet, Profibus, etc.)

- Heavy and extremely heavy duty starting possible

- and so on