Agriculture

Separation of cattle manure

Due to lack of straw, a farmer was looking for an alternative bedding material for the cubicles of his 240 dairy cows. He opted against expensive sawdust and installed a Bioselect.

The control unit coordinates the operation of the components perfectly. The farmer selects a high DS content (>30 %) for use as bedding material and a low DS content (approx. 22 %) when the solid phase is to be delivered to a biogas plant. Using the separated solid phase as bedding material works very well. The cows like to lie on the soft material and the bacteria count in the milk continues to be at a very low level.

Agriculture

Mobile high-performance separation

The mobile Bioselect RC 150 is fed by a Börger Rotary Lobe Pump The control technology continuously measures the capacity utilization of the separator and automatically varies the feeding quantity. This ensures optimal utilization of the separator.

In order to protect the pumps and the separator from impurities, the medium is conveyed through a Börger Rotorrake first. The macerator shreds the fiber bundles while the impurities are collected in the stone trap. The power required by the machines is produced by an 88 kW power generator.

A 10 m (32.8 ft) pivotable conveyor belt transports the separated solids to the required location.

Agriculture

Mobile vat filling station

A liquid manure organization was searching for a mobile vat filling station. Their priority was to have a mobile pump with chopper unit, as the medium often contained solids which could lead to blockages in the spreading device at a later stage when spraying the liquid manure. They also wanted to have a compact model.

The organization decided on a vat filling station from Börger. Besides the high-performance rotary lobe pump and the efficient Börger Rotorrake, the customer was also extremely impressed with the service Börger offered. The customized unit was completely supplied by Börger GmbH according to all the requirements of the customer.

The pump is operated via the PTO of a tractor. A low maintenance chain drive operates the Rotorrake via the second shaft of the rotary lobe pump. A slip clutch ensures maximum safety. The boom system installed above for filling the vats can be adjusted using the tractor hydraulics. This boom can be rotated manually up to 360°. The liquid manure organization is now highly satisfied with their customized filling station.

Agriculture

Mobile liquid manure pump

A contractor was looking for a mobile pump to transfer liquid manure and fermentation substrate. The pumps needed to be used in tanker vehicles in various agricultural operations. It was important for the contractor to have a compact pump which could deal with high pumping volumes and which was resistant to solids. The customer opted for a Börger Rotary Lobe Pump. Besides fulfilling the above-mentioned criteria, the key to the decision was that Börger GmbH carried out all the work from the planning of the mobile unit, the design and the construction of the trailer and the controls. This ensured that all the customer requirements could be taken into account and a custom-made mobile unit which fulfilled the contractor's demands was made.

To operate the unit from all sides, it was fitted with an electronic remote control. The unit can be started and stopped with the remote control. Furthermore, the speed and direction of transfer can be easily changed.

The built in transfluid power shift transmission ensures a long service life for the gears and drive in reversing mode. The customer is extremely pleased with the Börger mobile unit. The high pump output, reversing control and remote control operation have already significantly increased the unit's productivity compared to the unit used before by the customer.

Agriculture

Separation

An agricultural contractor uses a powerful mobile Bioselect. Easy operation and a flexible installation were especially important to the contractor. Since on the farms of many customers the maneuvering area is quite small, the separator had to be rotatable. A Börger rotary lobe pump conveys the substrate to be separated into the Bioselect. The control unit regulates the pump speed and the feeding quantity depending on the utilization of the Bioselect.

Agriculture

Liquid manure storage

For the storage of liquid manure, a farmer opted for two Börger stainless steel tanks with a capacity of 2,528 m³ (667,827 gal) each. By using two storage tanks the farmer is able to reduce the content of phosphorus in the liquid manure by means of a special sedimentation process.

In addition to the high quality of the Börger tanks the customer was convinced in particular by the lasting value as well as the option to increase the capacity of the tanks later on.

Due to current legislation the tanks were equipped with a roof for emission protection. For tanks without a roof retrofitting is possible anytime with ease.

Agriculture

Mobile vat filling station for tractor hoist

A customer required a powerful mobile vat filling station for top and bottom filling of transport and spreader vehicles. The station was supposed to be driven by the tractor PTO and to be attached to the tractor hoist.

The Börger mobile vat filling station for the tractor hoist impresses customers with its compact dimensions and

flexible installation options. After the PTO shaft has been connected, the boom can be extended to a height of 4.20 m (13.7 ft) by tractor hydraulics. The loading reach is more than 2.00 m (6.56 ft) so that even large transport and spreader vehicles can be filled without any problems. The pipes have a DN 200 design. The boom has an own storage place when it is not used. The horizontal alignment can be adjusted manually. The vat filling station has the mounting category 2.

Agriculture

Circulation system

In a circulation system a cattle farmer used 3 PTO mixers which were driven externally by the PTO shaft of his tractor. As part of a barn enlargement the cattle farmer now uses three Börger submersible mixers B-MX. The submersible mixers completely made of stainless steel could be attached to the existing guide rails of the replaced PTO mixers. Propellers with a diameter of 400 mm (15.7 inch) were selected due to the low space. The submersible mixers are driven by a 9 kW electric motor.

Agriculture

Liquid feeding

When the animals of a farmer were fed with by-product food components such as potato steam peels, fruit, vegetable or pastries and confectionery, blockages occurred frequently in the feeding pipes and valves of the feeding plant. In particular, hard Christmas decoration in old bread that does not dissolve in the mixing process poses problems. A Börger Multicrusher was installed into the pipeline system upstream of the feeding pump. Due to the high degree of maceration, the liquid feed even flows through slim pipeline systems and feeding valves in the barn without any problems.

Agriculture

High-performance vat filling

A large agricultural contractor from Luxembourg uses a mobile vat filling station from Börger for filling their vats.

The pump sucks the liquid manure through a Börger Rotorrake. The single-shaft macerator shreds the solids. There are three hydraulic circuits from the on-board hydraulics. One hydraulic circuit drives the pump, the second is used for the Rotorrake and the third hydraulic circuit can move the extendable docking arm. There is a 200 l (52.8 gal) tank for Piadin on board of the vat filling station. The Piadin can be fed into the liquid flow by means of a dosing pump. An integrated flow meter ensures exact dosing. An auto stop function automatically stops the pump as soon as the vat to be filled is full.

Agriculture

Separation of cattle manure

Due to lack of straw, a dairy farmer was looking for an alternative bedding material for the cubicles of his 240 dairy cows. For economic reasons he opted against expensive sawdust and for a separator.

He installed a Bioselect RC 40 separator with Börger control technology and a BLUEline rotary lobe pump. The control unit coordinates the operation of the feed pump, the liquid phase pump and the separator perfectly. Automatic separation at required times can also be selected.

The DS content in the solid phase can be continuously adjusted with ease. Thus, the farmer selects a high DS content (>30 %) for use as bedding material and a low DS content (approx. 22 %) when the solid phase is to be delivered to an associated biogas plant, saving storage capacity of up to 25 %.

Using the separated solid phase as bedding material works very well. The cows like to lie on the soft material and the bacteria count in the milk continues to be at a very low level. The customer is very satisfied with his Bioselect.

Agriculture

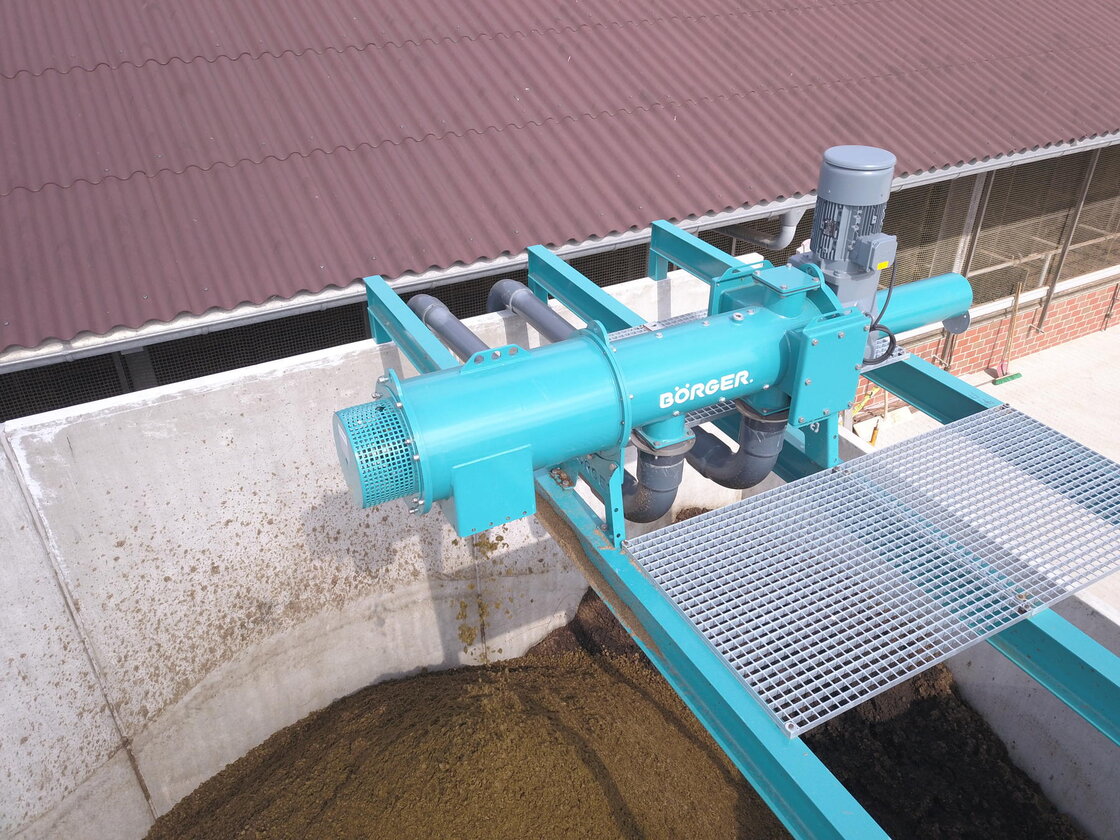

Mobile Bioselect RC 150

For the separation of liquid manure and digestate an agricultural contractor uses a Bioselect RC 150 installed on a trailer. The press auger separator achieves a maximum capacity of up to 150 m³/h (660usgpm), with a Börger rotary lobe pump feeding the Bioselect directly and without intermediate container. The Börger control technology continuously measures the capacity utilization of the separator and automatically varies the feeding quantity. This ensures that the separator always operates at its optimal capacity.

In order to protect the pumps and separators from impurities, the feed pump sucks the medium to be separated through a Börger Rotorrake The macerator shreds the fiber bundles while the impurities are collected in the stone trap. This guarantees long service lives of the pump and the separator.

The power required by the machines is produced by an 88 kW power generator. A 10 m (32.8 ft) pivotable conveyor belt transports the separated solids to the required location. The DS content in the solid phase can be continuously adjusted between 18 and 38 % by the control technology. The liquid phase is conveyed directly to the required storage location by a Börger rotary lobe pump in the closed system.

Agriculture

Nutrient management on a pig farm

A pig farm uses a Bioselect RC40 to adjust the solid content of pig manure. When the manure enters the separator, it has a dry solids content of approx. 5 %. The Bioselect separates the solid from the liquid phase. The DS content in the solid phase is infinitely variable up to 38 %. The customer separates with a DS content of 22 %. This way, the stackable solid phase that is passed on to a biogas plant contains large quantities of liquid.

Since the solid phase has a high nutrient concentration, the farm provides many nutrients. In addition, the farmer saves storage space. The separated liquid phase can be spread very well. It runs easily down the leaves and quickly penetrates the soil