Sugar & starch industry

Raw sugar process

A major German sugar producer required a pump to convey the raw sugar syrup at its plant. In the crystallization production sequence, the water is extracted from the sugar beet syrup in a vaporization crystallizer. Sugar crystals are formed in the process with the help of seed crystals. The resulting mass is a mixture of 50% sugar crystals and viscous syrup. Once cooled down, the sugar crystals separate from the viscous white sugar syrup in a centrifuge. After spinning, the white sugar syrup goes to a boiling station again for crystallization. The resulting syrup separated from the sugar crystals is called raw sugar syrup and is pumped to the post-product station.

The customer opted for a Börger rotary lobe pump. The pump's ease of maintenance and the sophisticated seal construction particularly impressed the customer.

Sugar & starch industry

Sugar beet syrup

Bioethanol refers to ethanol made exclusively from biomass or biodegradable portions of waste, for use as biofuel. Bioethanol can be made from any raw material that contains sugar or starch. It is often obtained from sugar beet syrup. The sugar beet syrup is made in a sugar factory.

A major ethanol manufacturer required a pump for unloading the tanker trucks which delivered sugar beet syrup. The pump had to be able to convey the highly viscous syrup, be self-priming and pressure resistant up to 8 bar (116 psi).

The ethanol manufacturer chose a Börger Rotary Lobe Pump.

Sugar & starch industry

Binder

A sugar producer was looking for a pump for conveying binder.The customer decided on a Börger Rotary Lobe Pump. Besides the low price and the resistance to sugar crystals, the key to this decision was the Börger Rotary Lobe Pump's ease of maintenance.

The Rotary Lobe Pump is operated at speeds of up to 100 rpm due to the high viscosity of the binder. Due to the abrasive ingredients of the medium, the pump was equipped with replaceable casing liners and Premium stainless steel rotors. Maintenance of the pumps can be performed by in-house personnel on site at the sugar producer's by simply undoing a few screws. (MIP = Maintenance in Place)

Sugar & starch industry

Sugar solution

A sugar producer needed a pump for conveying sugar solution. After the thin juice extracted from the sugar beet has been cleaned and run through the vaporization station it is called syrup.

Remaining water is extracted from the syrup in the boiling station at reduced pressure. Once a certain sugar concentration has been achieved, fine sugar crystals are added to the viscous juice using seed crystals. The seed crystals grow to the required size with further water extraction. The crystallization process is then complete and the crystals are left to cool down. They are then separated from the viscous syrup by spinning in centrifuges. The crystals are caught in a filter while the syrup flows through. To produce refined sugar (especially pure high-quality sugar), the crystallized sugar is dissolved. This is then called sugar solution. Refined table sugar is made by crystallizing this solution once again. It was important for the sugar producer that the pump be sufficiently robust for this process and that maintenance could be performed on site by in-house personnel without time consuming dismantling. The customer opted for a Börger Rotary Lobe Pump.

Sugar & starch industry

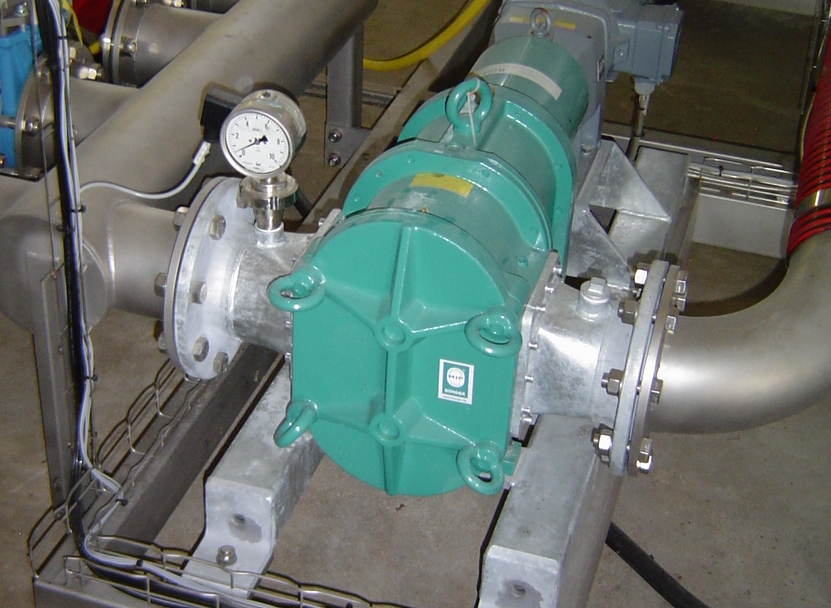

Lime milk

In the sugar manufacturing process, raw juice is extracted from sugar beet or cane. After extraction, the raw juice still contains various organic and non-organic substances which would interfere with the following production steps. These non-sugar substances must then be removed.

Lime and carbon dioxide are obtained by burning limestone in lime kilns. The lime is then added to the raw juice in the form of lime milk so that suspended matter flocculates and the unwanted non-sugar substances coagulate.

A French sugar manufacturer has been using a Börger Rotary Lobe Pump for conveying lime milk now for the past 9 years. They are particularly impressed with the reliability and the long service life of Börger pumps.

Sugar & starch industry

Molasses

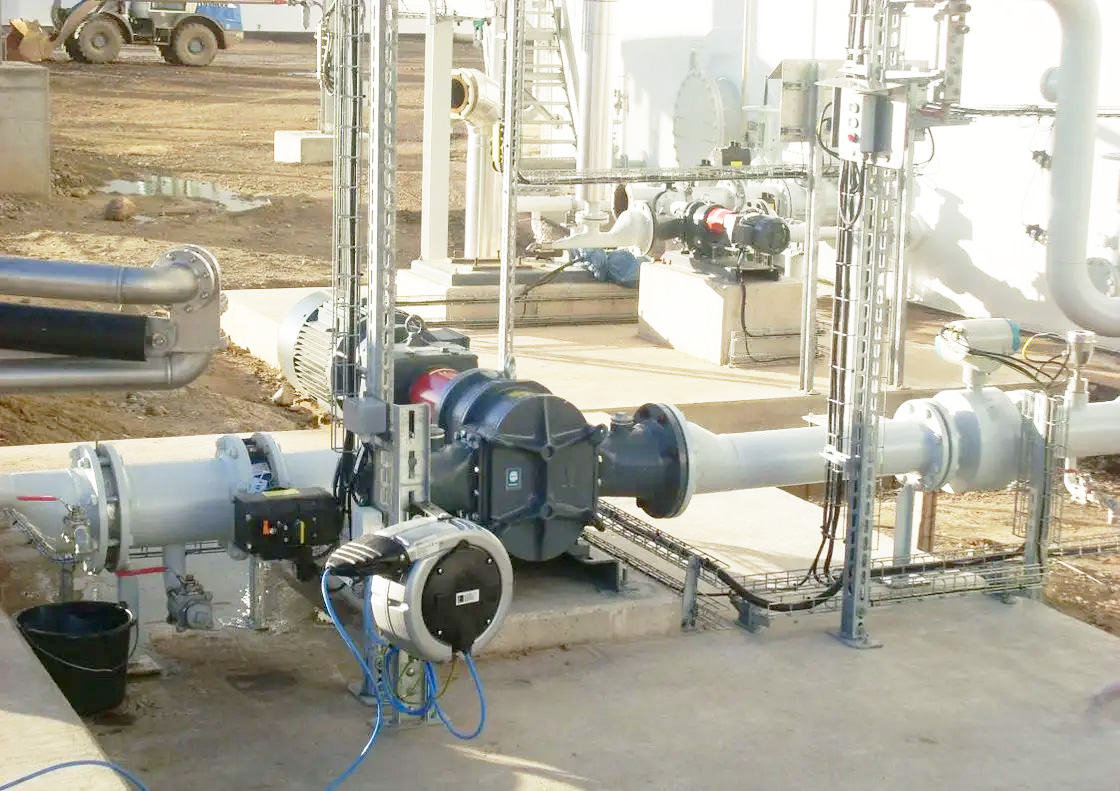

A customer produces alcohol made by extracting ethanol and methanol from molasses (a by-product from sugar production). The molasses is stored in tanks. A new pump was needed to transfer the daily quantity required for production into a day tank from the storage tank.

The pump had to be able to convey viscous media as well as be robust in design and easy to maintain. The customer was also looking for a solution for regulating excess pressure as they experienced problems with the previous pressure relief valve installed. The sugar medium accumulated and hardened in the opening of the valve.

The producer of potable alcohol decided on a Börger Rotary Lobe Pump with a Börger Variocap as overpressure protection. The force resulting from the pump pressure acts on the Variocap. As long as the spring force is greater than the pressure, the plate stays in the sealed position flush to the pump chamber. If the pressure rises above the set spring force, the plate moves axially and allows the pumped medium to flow back. When the pump pressure decreases, the gap closes again.

Sugar & starch industry

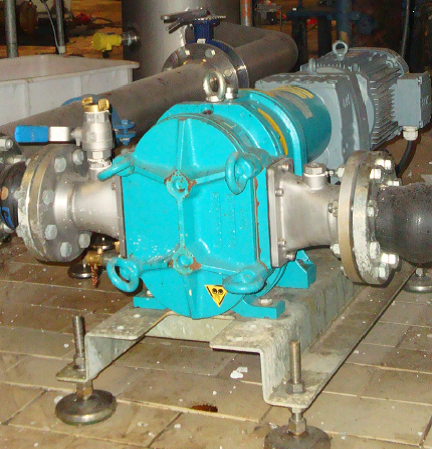

Magma

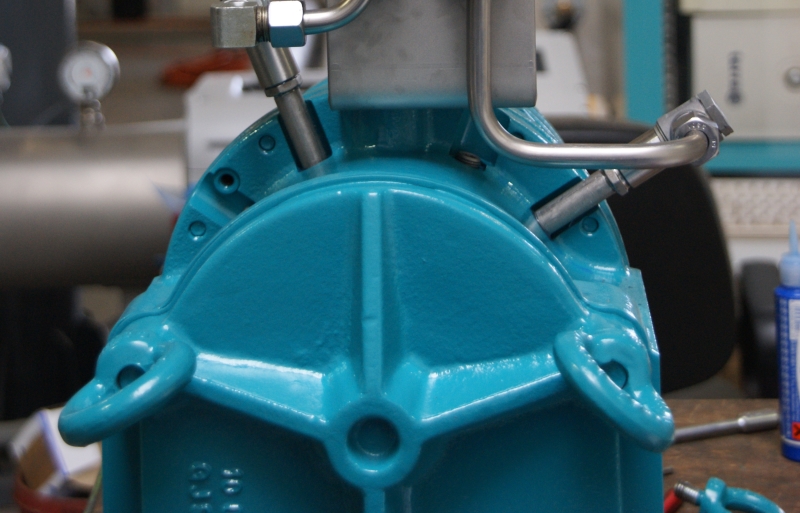

A sugar producer was looking for a reliable pump which could cope with the high viscosity and abrasiveness of magma. The producer decided on a Börger Rotary Lobe Pump.

The magma hardens if it does not keep flowing. To protect and keep the seals clean in the Börger Rotary Lobe Pump, a rinsing unit was integrated in the pump which rinsed the seals when in standstill to prevent the build-up of magma on the sliding surface. The Börger Rotary Lobe Pump is fitted with linear stainless steel rotors. These are resistant to the sugar crystals which occur in the magma and ensure a long service of the rotary lobe pump.

The customer is highly satisfied with the Börger Rotary Lobe Pump and has since ordered more pumps from Börger.

Sugar & starch industry

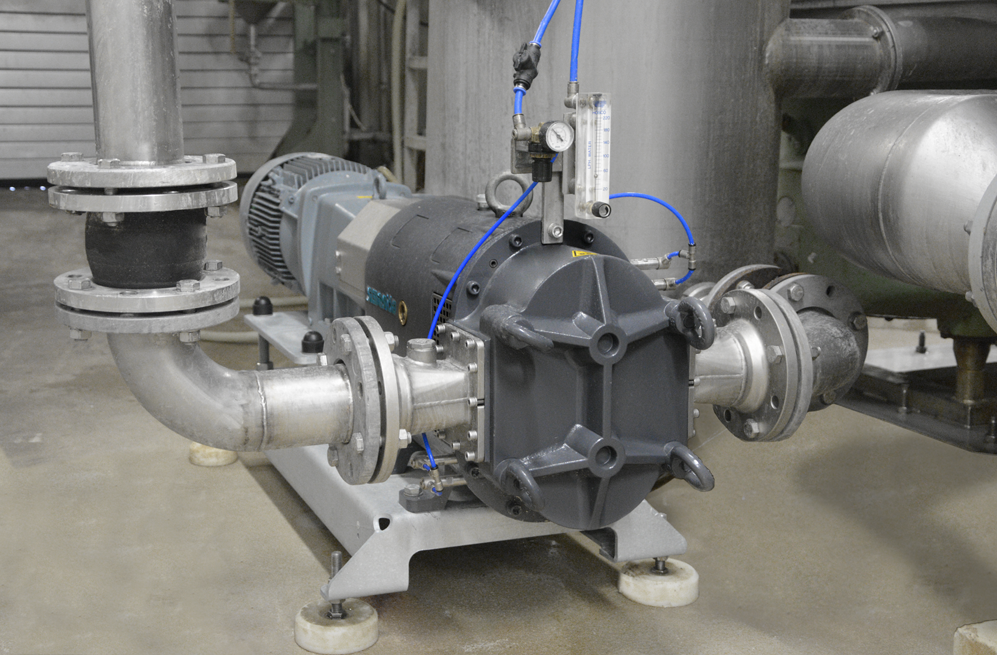

Crystal slurry

An international manufacturer of starch and starch derivatives was searching for a reliable pump to transfer crystal slurry. The food manufacturer's main priority was to have a smooth production process as any disruptions would lead to huge expense.

The manufacturer had several different pumps installed for transferring the crystal slurry. All of the pumps installed had suffered serious problems dealing with the pumped medium. The crystal slurry hardens quickly and is highly viscous with a solids content of up to 75% DS. The previous pumps had sealing faults, as the medium coagulated on the sealing surfaces of the mechanical seal and dried there.

Now the customer is using a Börger Protect Rotary Lobe Pump. The Börger Protect is equipped with double-acting mechanical seals. A Börger thermosyphon system ensures the pressure for the mechanical seal. This prevents the medium from accumulating on the sliding surfaces of the mechanical seal. The Protect model is fitted with a heated cover to ensure the medium does not cool down inside the pump.

The customer is extremely satisfied with the Börger Protect Rotary Lobe Pump. Production downtime due to faulty mechanical seals is now a thing of the past. Any maintenance work can also be performed very quickly due to the Börger pump ease of maintenance design (MIP = Maintenance in Place). Plant productivity also improved.

Sugar & starch industry

Wheat starch

A global company producing wheat flour, wheat starch and wheat gluten for food, pet food and non-food industries uses a Börger BLUEline Protect rotary lobe pump for conveying C solution.

The pump made of stainless steel is equipped with a double-acting mechanical seal which is pressurized with 5 bar. This way, the pumped medium cannot come into contact with the sealing surfaces of the mechanical seal.

The pump is cleaned by means of a CIP process before each standstill. In this process, the pump conveys the cleaning liquid which has a temperature of 85 °C (185 °F).

Sugar & starch industry

C starch

A large wheat mill uses a Börger ONIXline rotary lobe pump for conveying very abrasive C starch. C starch is produced when wheat starch is separated from the wheat gluten. When a specified fill level has been reached, the C starch is conveyed from an underflow tank into the product tank. The rotary lobe pump operates 24 hours on 7 days a week for 365 days a year. The speed and, thus, the flow rate is regulated by means of control technology. The pump is equipped with Börger double-acting mechanical seals as cartridge versions. The seals are pressurized by a barrier pressure system. This prevents any pumped medium from penetrating between the sliding surfaces of the seals. The pump has operated without interruptions since its installation.