The production of paper often requires a special design of the pumps used. Media such as coatings or fluids containing latex place high demands on the sealing technology. The big sealing chambers of our pumps offer space for a large selection of seals. This way, we always find the right sealing technology for every application.

Paper, cardboard & tissue

Calcium stearate

An international manufacturer of olechemicals and additives was looking for a pump for conveying liquid calcium stearate. The calcium stearate is used in building materials and paper industries. Previously, the company had been using an eccentric screw pump. However, breakdowns in the stator repeatedly led to considerable downtime and costly repairs. The eccentric screw pump invariably had to be dismantled for repairs and maintenance. The chemicals company was looking for a robust pump that didn't need to be dismantled for maintenance.

They opted for a Börger Rotary Lobe Pump with pressurized intermediate chamber. Besides the wide choice of material and the proven long service life, the key to this decision was the Börger Rotary Lobe Pump's ease of maintenance.

Paper, cardboard & tissue

Paper sludge

In the paper manufacturing process, the filter and press water is extracted from the fibrous water suspension in the paper machine. There are various levels of retention which depend on the type of paper being manufactured and the composition of the fibrous water suspension. The retention indicates the proportion of the fibers, fillers and fines left in the filter compared to the complete retention of the substances in the wastewater.

In the manufacture of hygienic tissues, such as toilet paper, tissues or facial tissues, a lot of fibrous substances remain in the water from filtering and pressing the fibrous water suspension.

This water is treated in the in-house wastewater facility. The solids are thickened before liquid is being removed from the solids in a filter belt press. To transfer the water with all the solids into the filter press, a Börger Rotary Lobe Pump is used at the paper factory in West Germany.

Paper, cardboard & tissue

Coatings

A paper manufacturer was looking for a pump to convey a special coating for finishing paper. The paper becomes stronger and more resistant to water with the application of this coating. The paper manufacturer had previously been using an eccentric screw pump. However, due to the eccentric screw pump's frequent downtime and the high cost of spare parts, the customer sought an alternative. The paper manufacturer opted for a Börger rotary lobe pump.

The coating color hardened if it was not kept flowing or if it dropped below a temperature of 20 °C (68 °F). To protect the seals of the Börger rotary lobe pump and to keep it clean, a rinsing unit was fitted to the pump which rinsed the seals after every charge. The intermediate chamber is constantly rinsed from the bottom to the top.

The customer is extremely satisfied. Now, through lack of downtime, the customer has already regained the cost of the pump after 8 months. The quality of the end product could also be optimized as the Börger pump with frequency control is a better design than the previous eccentric screw pump.

Paper, cardboard & tissue

Wood powder slurry

A paper and cardboard manufacturer uses recycled paper and wood powder in his plant to make cardboard. The wood powder (a fine sawdust) has the advantage of providing a lot of bulk to the cardboard yet still being very lightweight.

The wood powder is delivered and stored in a dry state. Before entering the production process, it is fluidized with water. To pump this wood powder slurry to a storage tank, the manufacturer uses a Börger Rotary Lobe Pump.

From the storage container, the frequency-regulated Börger rotary lobe pump dispenses the wood powder slurry into the production process in doses.

Paper, cardboard & tissue

Process water from second cleaner stage

In a company producing corrugated board base paper the separated process water, which is produced in the so-called “second cleaner stage“, flows from five cyclones into a small tank with a screen insert. A Börger rotary lobe pump in a stainless steel-version conveys the process water into a vibrating screen for further processing. Here the solids still contained in the water are separated. Afterwards, the water is conveyed to a solid/liquid separator. The solids are burnt. The filtrate is reused as gray water for paper production.

Paper, cardboard & tissue

Pellet sludge

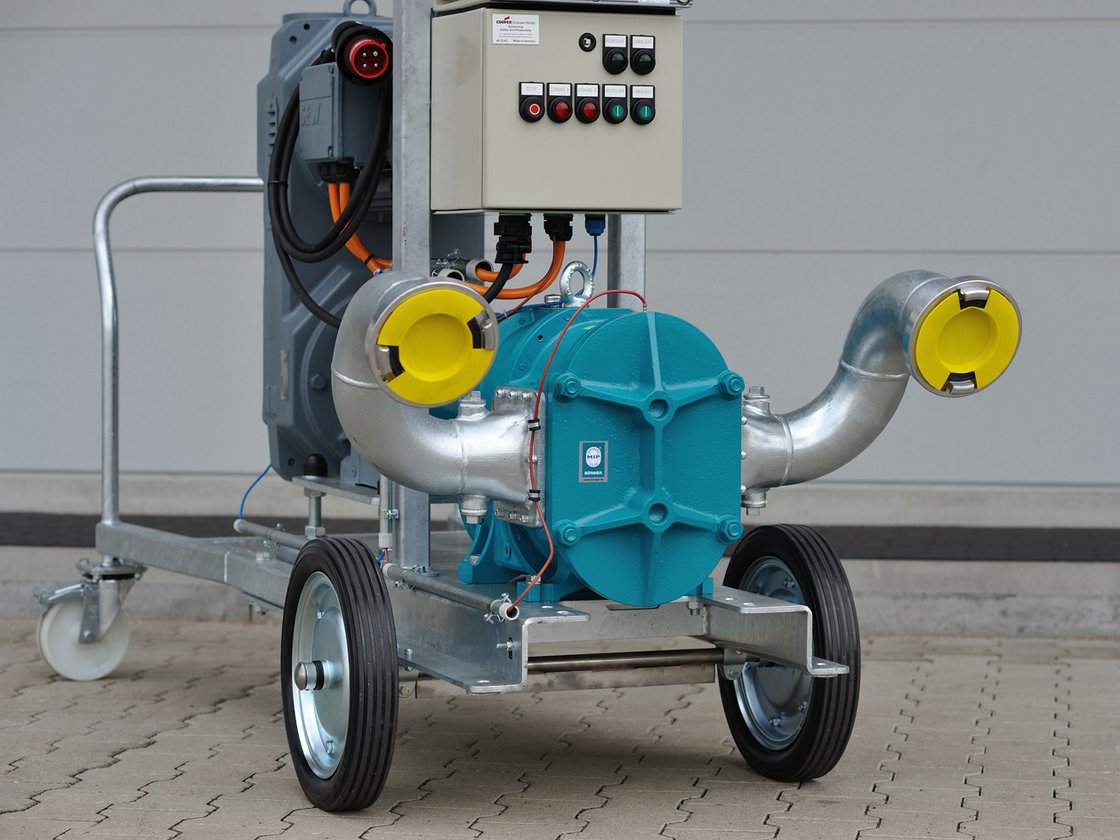

A Scandinavian manufacturer of tissue products uses a mobile Börger rotary lobe pump with ATEX-compliant design for conveying pellet sludge. The customer was particularly impressed by the gentle pumping of the medium and the ease of maintenance of the Börger rotary lobe pump.

Paper, cardboard & tissue

Latex

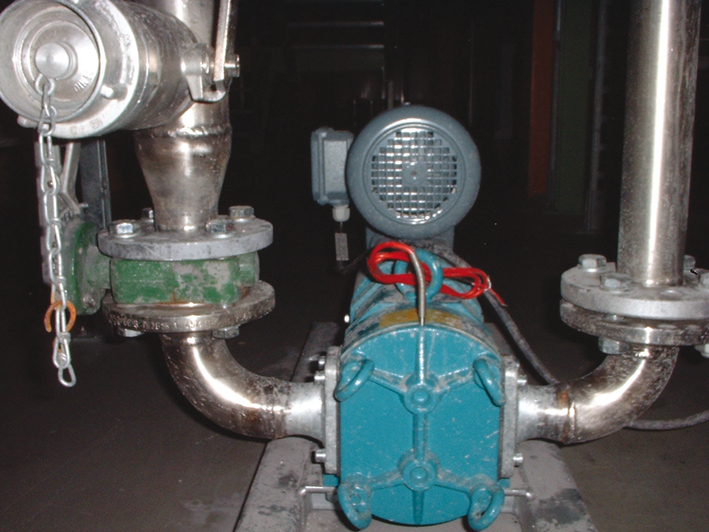

At the chemicals collection point of a printing paper manufacturer, the Börger pump empties the tanker trucks and conveys the latex into the storage tanks of the coating kitchen for further use. The stainless steel pump is equipped with double-acting mechanical seals. The mechanical seals are pressurized by means of a thermosyphon system. The pump was installed vertically next to the two other Börger pumps due to the limited space available.

Paper, cardboard & tissue

Pump in coating kitchen

A paper manufacturer specializing in the production of special papers and wet-strength label papers uses a Börger rotary lobe pump for conveying coating color from the coating kitchen into the paper machine. The pump has individually pressurized shaft seals. This prevents any pumped medium from penetrating between the sliding surfaces of the seals. The tri-lobe screw rotors convey the medium with low pulsation.

Paper, cardboard & tissue

Process water containing solids

A Norwegian chemical company specializing in the production of raw materials for paper manufacturing uses an ONIXline rotary lobe pump for conveying process water containing solids. The pump conveys the medium with chemically aggressive components into a preheater. The fluid has changing viscosities from water-like consistency up to 6,000 mPas. The pump is operated by a frequency converter. The pump speed is adapted to the viscosity of the pumped medium. The efficiency of the ONIXline rotary lobe pump remains consistently positive even with changing viscosities and pressures of up to 14 bar (203 psi). Productivity was improved and energy consumption reduced.

Paper, cardboard & tissue

Wastewater tanks

An international corrugated cardboard manufacturer required two wastewater storage tanks for its own water treatment facility.

They opted for a Börger elevated tank, type 13.6 with a total volume of 1,025 m³ (4510 usgpm) and a Börger elevated tank, type 04.3 with a volume of 49 m³ (215.6 usgpm).

Paper, cardboard & tissue

Bulking agent

A customer from the paper industry was looking for a pump with dry-run capability to transfer liquid bulking agent. The system also had to be very easy to maintain – that's why a Börger Rotary Lobe Pump with radial casing liners quickly came up as the ideal solution. Result: The result: high reliability and lower operating costs.

Paper, cardboard & tissue

Lime milk

An industrial company decided on a Börger Rotary Lobe Pump for conveying lime milk. Fully elastomer-coated rotors and silicon carbide mechanical seals meet the requirements of the highly abrasive pumped medium in an ideal manner. The low speed ensures gentle pumping and a long service life of the medium-wetted parts.

Paper, cardboard & tissue

Glue mixture

A Börger Rotary Lobe Pump was installed at a packaging manufacturer for conveying a thick glue mixture in the production of corrugated cardboard. It is suitable for intermittent operation and also runs reliably and practically trouble-free even with this highly adhesive pumped medium thanks to the multi seal K shaft seal system.

Paper, cardboard & tissue

Boiled starch

A manufacturer of corrugated base paper has been using a Börger rotary lobe pump for conveying boiled starch.

Following a procedure conversion, the starch can reach temperatures of up to 120 °C (248 °F) and has a solids content of 17 %. In the eccentric screw pump used before, the starch was not allowed to exceed a maximum temperature of 80 °C (176 °F) and the pump suffered from excessive wear. The rotary lobe pump used now is completely made of stainless steel. Casing protection plates and liners made of stainless steel protect the pump casing from wear and the pump is equipped with tri-lobe screw rotors made of stainless steel. These rotors convey the boiled starch with very low pulsation.

Paper, cardboard & tissue

Starch

A manufacturer of magazine paper uses a Börger ONIXline rotary lobe pump for conveying starch.

The pump conveys the starch from the coating kitchen into the coater. The starch increases the paper’s strength. The ONIXline pump is equipped with pressurized, double-acting mechanical seals. Stainless steel rotors with screw profile convey the very abrasive starch with low pulsation.