Photos

High-quality and reliable

There are hardly any limits when installing a mobile pump. Whether as a flood pump on a trailer, a mobile PTO shaft pump or as a hand cart pump offering flexible use. The mobile units are supplied from a single source. Börger produces the chassis, pump technology and control technology themselves.

Options

Versatile

Everything is possible. Börger rotary lobe pumps are suitable for a large variety of mobile applications.

Whether as a high-performance flood pump on a trailer, a flexible emergency pump with three-point mounting or a portable hazardous material transfer pump, every Börger pump is manufactured individually for its specific application.

High-performance pumps

Powerful and fully independent

Börger high-performance mobile pumps can be mounted on a car or truck trailer. Driven by a combustion engine, they work fully independently.

Whether a tarp / roof bow construction with a convertible roof or an additional power generator − nearly every request can be realized. The motor can be equipped with a sound enclosure for use in residential areas.

Emergency pumps

For terrain which is difficult to access

Emergency pumps are manufactured for terrain which is difficult to access. By means of the three-point mounting, the pump (at the front or rear) can be attached to a Unimog or a tractor, lifted and transported to the installation site.

Sufficient ground and off-road clearance is also provided to be able to drive through flooded or difficult terrain. The pump is driven by means of the PTO shaft of the vehicle at the operation site.

Hand cart pumps

Flexible use

The compact hand cart pump is designed and manufactured individually to suit your application. In addition to various drive options, different material and sealing variations are available.

This way, the Börger hand cart pump can be used as a hazardous material pump for conveying chemically aggressive substances for example. It can also be used in potentially explosive atmospheres.

Portable pumps

Light and compact

The portable rotary lobe pump can be built in such a compact way that the pump including the drive can be transported in a car trunk or storage compartment of an emergency vehicle without problems.

As an aluminum lightweight version, the pump and drive can be carried to places which are difficult to access or into a cellar.

Hazardous material transfer pumps

ATEX-compliant and easy to handle:

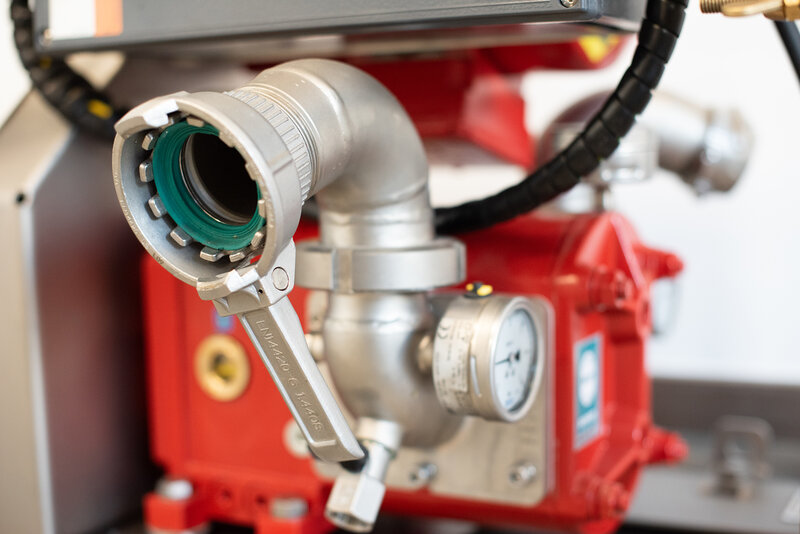

We have developed a portable hazardous material transfer pump (HMTP), especially for use in areas which are difficult to access. The solids-resistant pump is manufactured according to DIN 14427 and defined in DIN 14555 (table 1) as firefighting equipment.

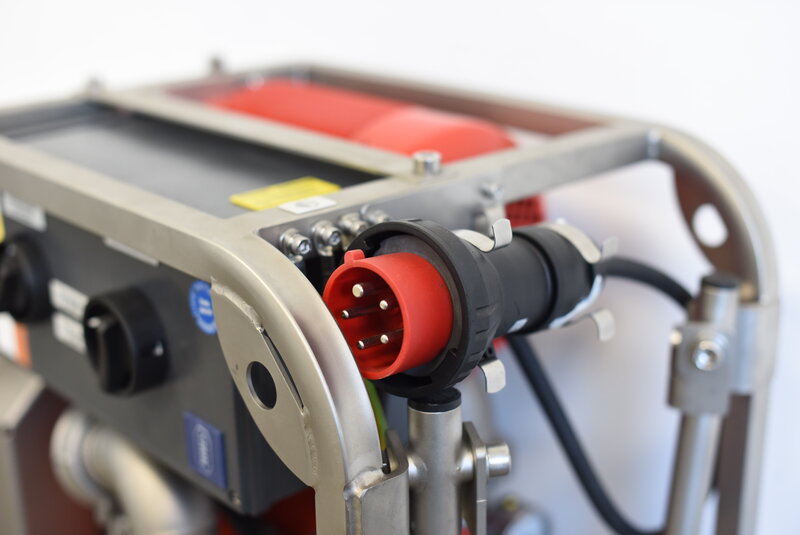

The ATEX-compliant rotary lobe pump is equipped with an explosion-proof electric motor and can be operated, for example, by the power generator of an emergency vehicle. The pump is self-priming. Additional priming aids are not necessary.

Benefits

Reliable, durable and ready for use right away

The compact, low-on-space design, unproblematic pumping in slurp operation and the possibility to drive a Börger rotary lobe pump by means of different motors or a PTO shaft are reasons why the Börger pump is the ideal mobile pump. The rotary lobe pump is also used on many roll-off containers.

A selection

- Ready for use right away: The rotary lobe pumps are ready for use straight away − connect the hoses and start the drive.

- Reliable and durable: The high quality down to the last detail is the reason why the Börger fire department pump is durable and reliable.

- Self-priming: The pumps are self-priming. A suction aid is not required.

- Pumping in slurp operation: Pumping in slurp operation is necessary in many cases.

- Resistant to solids: The pump is resistant to solids. Even the pumping of sludges containing solids is no problem.

- Short-term dry-run capability: A short-term dry run is possible without problems.

- Constant flow rate with high pressures: In contrast to the flow rate of centrifugal pumps, the flow rate of the rotary lobe pumps remains virtually constant even with high pressures (e.g. due to long pumping distances).

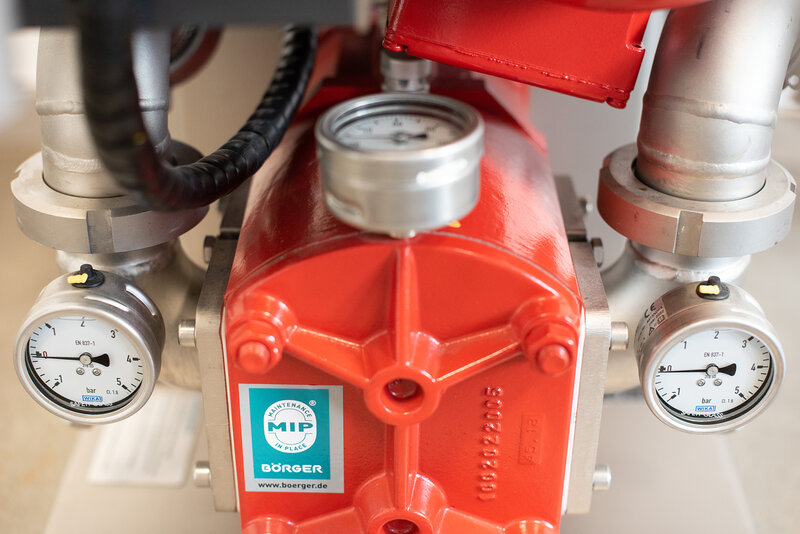

- Low life-cycle costs: Low wear, short maintenance times and low wear part costs.

- User friendly: The pumps are very easy to operate.

- Very easy to maintain due to MIP (Maintenance in Place): The pump can be maintained within a few minutes at any given location.

- ATEX-compliant: An ATEX-compliant pump design is available for use in potentially explosive atmospheres.