Disposal and recycling

Liquid waste

A disposal company uses Multicrushers for the maceration of solids in secondary fuels.

Tanker trucks deliver the liquid waste from different industrial companies to the incineration plant. The waste is mainly used solvents, used acids and used lyes. At the receiving points, the products are sampled before being removed from the tanker trucks and then conveyed into the product-specific tanks. Multicrushers are installed upstream of the pumps. They shred the solids contained in the delivered fluids effectively and reliably. This prevents blocking and damage to the pumps and pipelines.

The Multicrushers have an ATEX-compliant design and are permanently technically tight pursuant to TA Luft for use in potentially explosive atmospheres. In order to save space, the Multicrushers are driven by vertically installed motors.

Disposal and recycling

Secondary fuels

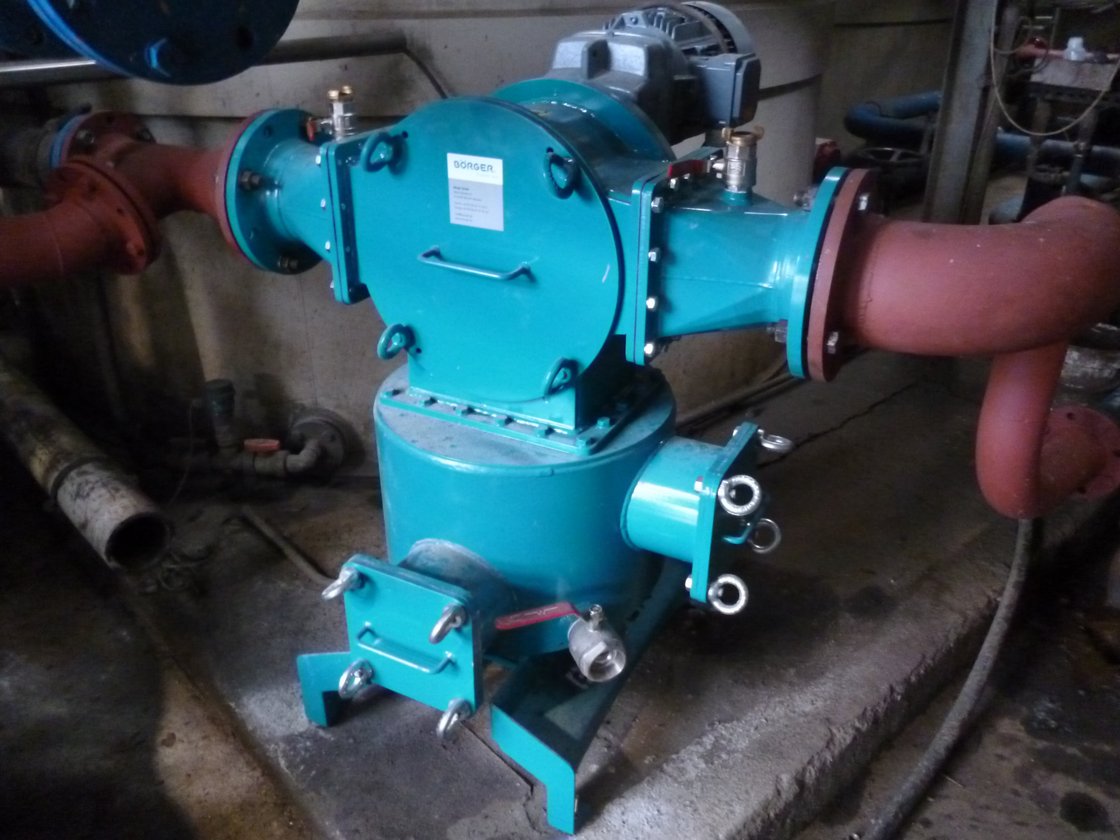

In a waste disposal company, a Börger pump feeds secondary fuels to the waste incinerator. The pump has to handle different ph values, viscosities and solids since various secondary fuels are to be used. What’s more, for firing the incinerator, precise metering and an even conveyance are the prerequisite for optimum operation of the lance burner in the waste incinerator. As the media to be conveyed are easily inflammable, the pump is built in ATEX-compliant design.

Disposal and recycling

Oil tank drainage

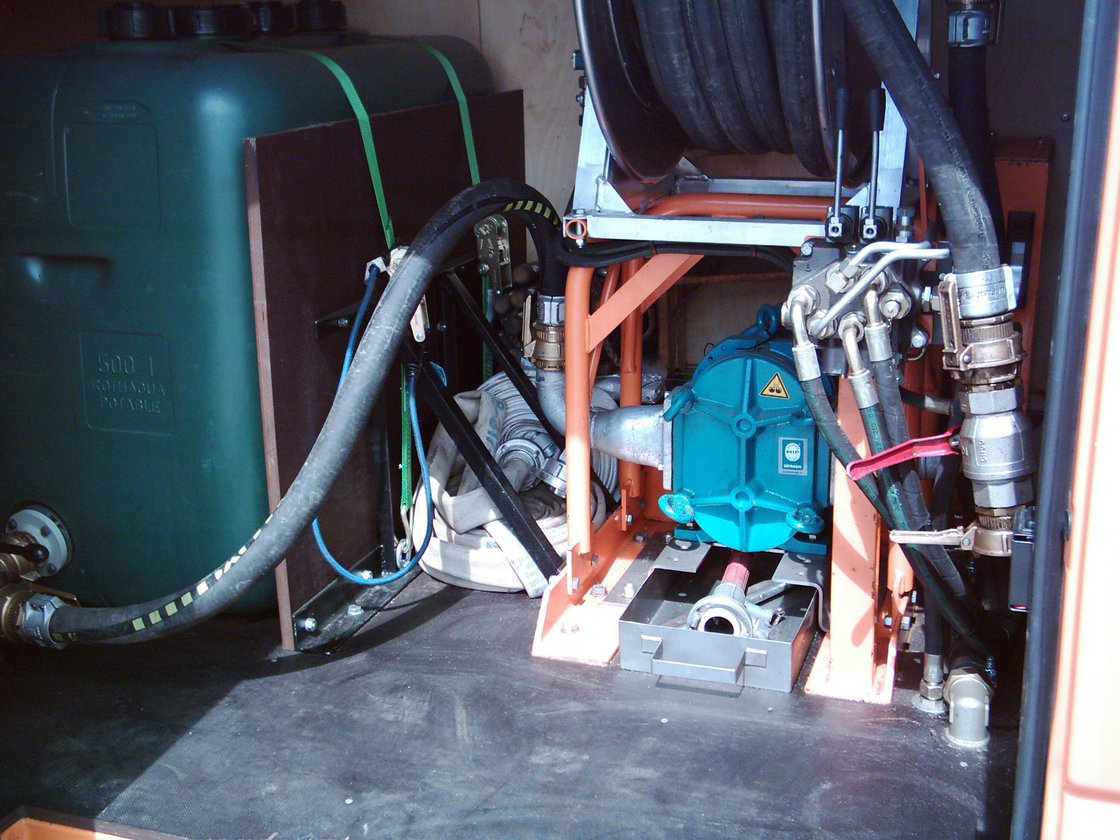

A disposal company has specialized in cleaning oil tanks. This involves removing used oil, oil sludge, fuel oil and grease separator deposits from the tanks to be cleaned into the mobile tanks of the disposal company using pumps mounted on tanker vehicles. Vacuum pumps are often used to do this which transport the medium into pressurized tanks. This solution involves high procurement and operation costs. The customer sought an easier and less expensive way to use PE tanks and avoid the high vehicle tare weight.

By using a Börger Rotary Lobe Pump, the disposal company was then able to use the PE tanks as mobile tanks. Due to its compact design, the Börger Rotary Lobe Pump can be installed on a pickup truck. The pump is powered hydraulically using the PTO from the pickup truck's engine. A three-way valve enables several tanks loaded in the pickup truck or on a trailer to be filled.

The reversible option of the pump is also able to discharge tanks on the vehicle and pump to other tankers using the Börger Rotary Lobe Pump.

Disposal and recycling

Polyethylene granulate

Old plastics are cleaned first of all and then chopped into pieces of approx. 5 – 10 mm (0.2 - 0.39 inch). The chopped plastic is then made into a polyethylene granulate in a special procedure (at a temperature of 110 °C (230°F) to a particle size of approx. 5 mm (0.2 inch)). This is used as a raw material in the manufacture of plastic pipes, buckets, toys, household equipment etc. At this phase, the granulate is malleable and easy to form due to the high temperature. To become sufficiently hard, the particles are cooled down to 20 °C (68 °F) in a water bath.

A Börger Rotary Lobe Pump ensures that the granulate keeps circulating in the cold water for approx. 20 min. to prevent the formation of any clumps when cooling down.

Disposal and recycling

Sodium sulfate

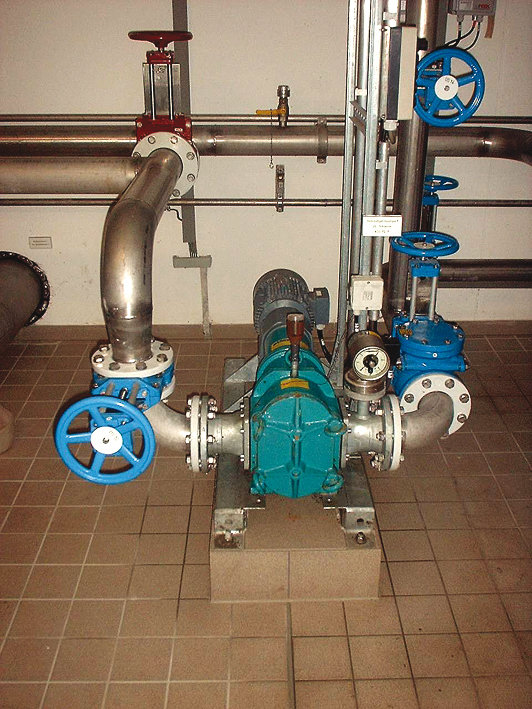

The customer runs an amine recycling plant. The amine sulfate delivered is processed in a rectification system. Caustic soda reacts with the sulfuric acid contained in the amine sulfate. The result is a sodium sulfate solution which is pumped into a storage tank. The Börger Protect Rotary Lobe Pump is used in the neutralizing process by adding sulfuric acid. The Börger pump conveys the sodium sulfate solution from the storage tank through a pipe system back to this storage tank. In the meantime, sulfuric acid is mixed in on the suction side. A pH value can be measured using a meter attached to the pressure side. This procedure is repeated until the sodium sulfate solution indicates a pH value of 7.

The eccentric screw pump previously used kept having problems with the sealing. As the air quality control requirements are applicable here, the Börger Protect Rotary Lobe Pump was selected. The barrier pressure was set to 8 bar (116 psi) in the thermosyphon tank. If the pressure drops below 5 bar (72.5 psi), a pressure switch turns off the system. The medium pressure is restricted to a maximum of 3 bar (43.5 psi) by a pressure transducer. This ensures a minimum barrier pressure of 2 bar (29 psi) above pump pressure.

Disposal and recycling

Flammable chemicals

A chemicals disposal company was looking for a pump for conveying flammable liquids. This pump had to be an ATEX model due to the composition of the media. It also needed to be used as a mobile unit. The disposal company wanted the pump for draining tanks so that pumping in slurp mode would also be possible.

They opted for a Börger Rotary Lobe Pump. A key factor in this decision was the wide variety of material, the customized design and the ease of maintenance of the Börger Rotary Lobe Pumps.

The mobile unit was equipped with an automatic control cabinet in accordance with ATEX guidelines. The control unit was fitted with a reversing control and a temperature controller.

Disposal and recycling

Separation facility

A company specializing in extracting water from sludge and processing contaminated sludge from the petrochemicals industry uses several Börger Rotary Lobe Pumps in a mobile separation system.

The entire separation is gas proof. The nitrogen used is for increasing the safety. The oil sludge to be purified is pumped to a centrifuge with a Börger Rotary Lobe Pump. Using the centrifuge, oil and water are separated from the sludge. Two additional Börger Rotary Lobe Pumps convey both the separated oil and the water to the intended containers. The customer wanted to have compact pumps in the mobile separation facility. The customer was impressed with the Börger Rotary Lobe Pumps due to the high processing quality and in particular, the low maintenance design. In a few steps, the pumps can be repaired by the customer's in-house personnel. Removing the pumps is not required. The pumps are built as ATEX models due to the explosive protection zone in the separation facility.

Disposal and recycling

Waste solvents, paints

Waste solvents and lacquers are collected in a basin. These media contain solids. The solids have to be macerated to be able to resell these highly flammable substances for energy production. To this end, the company uses a combination of a Börger pump and Multicrusher. This Börger duo pack is lowered to the ground of the basin filled with waste solvents and lacquers. The Börger rotary lobe pump constantly conveys the medium through the Multicrusher in circulating operation. The solids are macerated in this process. As the basin is declared an explosion-proof area, the rotary lobe pump and the Multicrusher were built in ATEX-compliant design.

Disposal and recycling

Waste oil

A disposal company was looking for a high-performance pump for a tanker truck. A number of different media is to be transported with the tanker truck and the customer wanted a pump which would cope well with solvents, waste oil, sludge and various chemicals. The pump also had to have a compact design.

The customer opted for a Börger Rotary Lobe Pump. The very compact, space-saving pump is powered by a hydraulic motor. The tanker truck can be filled and drained using the same pipe system since the rotary lobe pump is reversible. The Börger Rotary Lobe Pump is extremely easy to maintain (MIP=Maintenance in Place). The quick-release cover means that the rotors can be replaced in a matter of minutes. This proves great benefit for the disposal company as they have different rotors which could be installed in the rotary lobe pump depending on the medium in use at the time. This gave them the perfect rotor for each medium and avoided any unnecessary wear. The customer is very satisfied with the Börger pump.

Disposal and recycling

Sludge

An environmental service provider uses a Börger Rotorrake for macerating solids in front of a chamber filter press. Sludge from grit chambers, pump chambers and rain overflow basins are supplied in the coarse sludge receiving station of the environmental service provider. In the process, the solids-laden sludge passes a screen with a grid size of 100 mm (3.94 inch) and is collected in a receiving basin. The connected Rotorrake macerates the solids still left so that they cannot damage the chamber filter press. The Rotorrake is equipped with an automatic reversing control unit which prevents the solids from stucking.

Disposal and recycling

Photo chemicals

In a company situated in the Ruhr region, Germany, a Börger Rotary Lobe Pump is used for transferring photo chemicals in a recycling plant. The pump has a casing and flanged connections made of stainless steel and has been running for ten years to the full satisfaction of the customer.

Disposal and recycling

Plastic parts

In a recycling plant coarsely shredded plastic is washed and finely chopped simultaneously in one procedure. The mixture of plastic and water can then be pumped to the Börger Multicrusher. This chops the plastic parts reliably into the required product particle size.

Disposal and recycling

Separation of PET parts from washing water

A plastic recycling company producing polypropylene granulates from post-consumer plastics uses two Börger Bioselect RC 75 in its plant. The two Bioselect units separate plastic residues from the washing water. Reducing the residual water content helps to save a lot of energy in the recovery process.

Before purchasing the Börger separators, the plant had already tested several devices. The Bioselect reduced the residual water content to less than 20 %, whereas a residual water content of almost 50 % was measured in the plastic residues following separation by the other devices.

The two Bioselect RC 75 are integrated in the process. Due to process-related circumstances, the process flow feeding the Bioselect cannot be regulated. A control unit automatically adjusts the speed of the separators to the volume of the feed flow and the solids content contained therein. This ensures that the two separators always operate at their optimal capacity.

The operator of the recycling plant is very satisfied with the two Börger separators as they are very energy efficient. The customer was impressed by the high dewatering degree and the long service life of the separators.