Industrial wastewater treatment

Flotation tailings

The operator of a wastewater treatment plant was looking for a pump with dry-run capability for his flotation system. In the flotation system, substances on the surface of the flotation tank are suctioned off using a rotating suction arm.

Previously an eccentric screw pump had been used for this purpose. However, this pump had the disadvantage of needing extra water, to prevent dry running and required a lot of space and drive power.

The operator then opted for a Börger Rotary Lobe Pump. In addition to its dry-run capability, its minimum space requirements, the wide choice of material and the low drive power, the customer was also impressed with the low maintenance design of the Börger Rotary Lobe Pump.

Industrial wastewater treatment

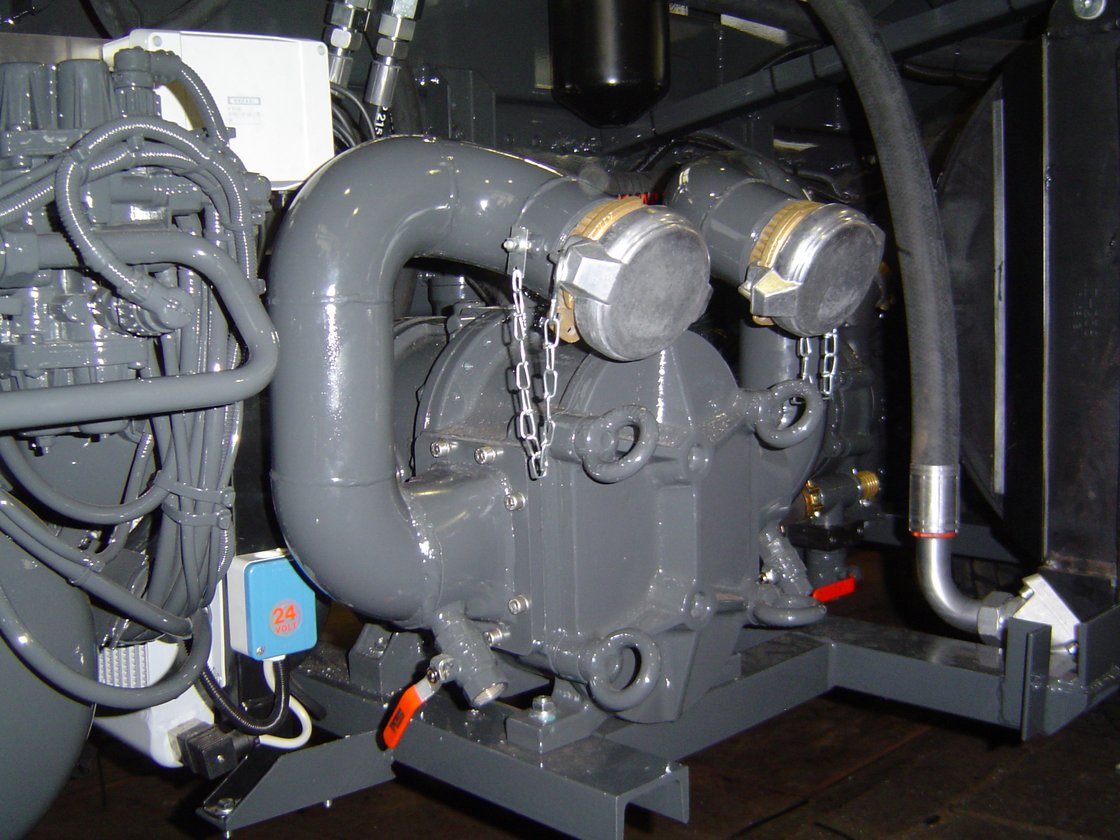

Sewer flushing

Börger Rotary Lobe Pumps are installed on many pressure tankers for municipal and private service providers. The pumps all have very different tasks. The Börger Rotary Lobe Pump is in a sewer flushing vehicle and extracts the wastewater through a coarse filter installed on the vehicle.

The initial purification takes place in the coarse filter. The still unpurified wastewater is then pumped into a centrifugal separator (cyclone). This cyclone separates other impurities (sand etc.). The clean water is then pumped to the storage tank in the vehicle and is then available for further use. The clean water is mainly used for flushing sewers.

Thanks to the reversibility of the pump, it can be used for other purposes. The pipelines to the suction and pressure side of the pump are fitted with cardan couplings. If required, these couplings can be connected to hoses or pipelines. This then also allows the storage tank to be filled or discharged with clean water. Due to the option of reversing the pump direction, the pipeline systems are easier to set up in the vehicle.

Industrial wastewater treatment

Wastewater containing fiber portions

In a textile company the wastewater from the bleaching process is conveyed into a tank. In addition to fiber material the wastewater also contains small portions of hydrogen peroxide and caustic soda. The fill level of the wastewater collecting tank is determined by means of a fill level gauge. When the defined fill level has been reached, a Börger rotary lobe pump is taken into operation via a control unit and conveys the wastewater from the collecting tank into the sewage system. In this process, the quantity of wastewater supplied to the sewage system is measured by a counter. The Börger rotary lobe pump is made of Duplex stainless steel and equipped with a maintenance-free mechanical seal.

Industrial wastewater treatment

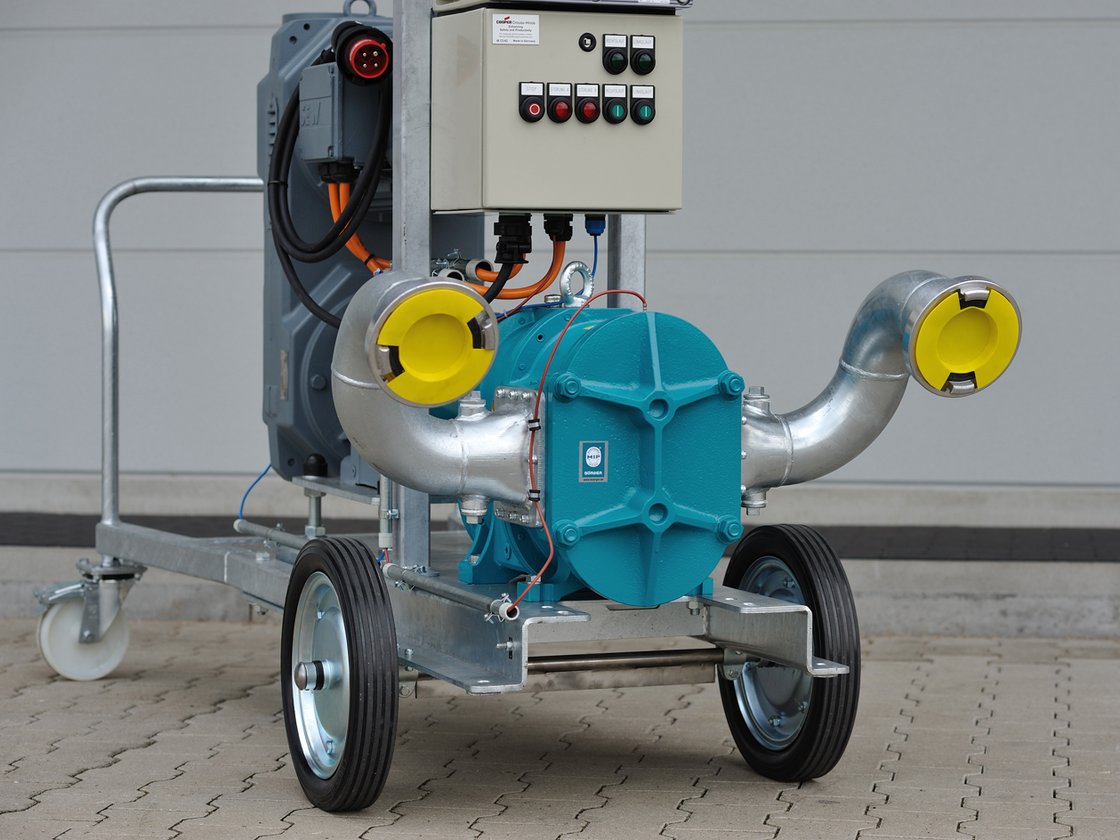

Pellet sludge

A Scandinavian manufacturer of tissue products uses a mobile Börger rotary lobe pump with ATEX-compliant design for conveying pellet sludge. The customer was particularly impressed by the gentle pumping of the medium and the ease of maintenance of the Börger rotary lobe pump.

Industrial wastewater treatment

Flotation sludge

In the wastewater treatment system of a manufacturer of soft foam rubber a Börger rotary lobe pump sucks the flotation sludge from the surface of the flotation tank. In the process, the viscous, foam-like sludge is sucked through a long suction line. Pumping in slurp operation is possible without problems and the pump is capable of running dry for a short time. The pump even conveys the more solid flotation layers without any cavitation and is resistant to changing proportions of gas in the pumped medium.

Industrial wastewater treatment

Wastewater tanks

An international corrugated cardboard manufacturer required two wastewater storage tanks for its own water treatment facility.

They opted for a Börger elevated tank, type 13.6 with a total volume of 1,025 m³ (270,776 gal) and a Börger elevated tank, type 04.3 with a volume of 49 m³ (12,944 gal).