Municipal wastewater treatment

Wastewater

The wastewater management department of a municipality was looking for a powerful mobile disaster relief pump. They opted for a high-performance Börger pump installed on a hookloader frame.

The rotary lobe pump is driven by an electric motor. The power required is produced by an emergency power generator, which is also installed on the L frame. This has the advantage that the pump can operate fully independently. In addition, the emergency power generator can be used independent of the pump to supply power to the municipal buildings in case of a power failure. In this case, it is possible to remove the pump with the electric motor and the control unit from the L-frame and to use them in a different location. The hookloader frame is equipped with numerous storage compartments and hose holders in line with the requests of the local authority.

Roller shutters protect the mobile unit against vandalism. The pump can be operated via the Börger control technology. In automatic mode, the pump is controlled via a fill level sensor. The pump regulates itself via the intelligent pump control system. The control technology is equipped with a remote monitoring function. A visualized pump control system allows the operator to monitor all operating states of the pump via cell phone, tablet or PC, even from home.

Municipal wastewater treatment

Wastewater, sludge

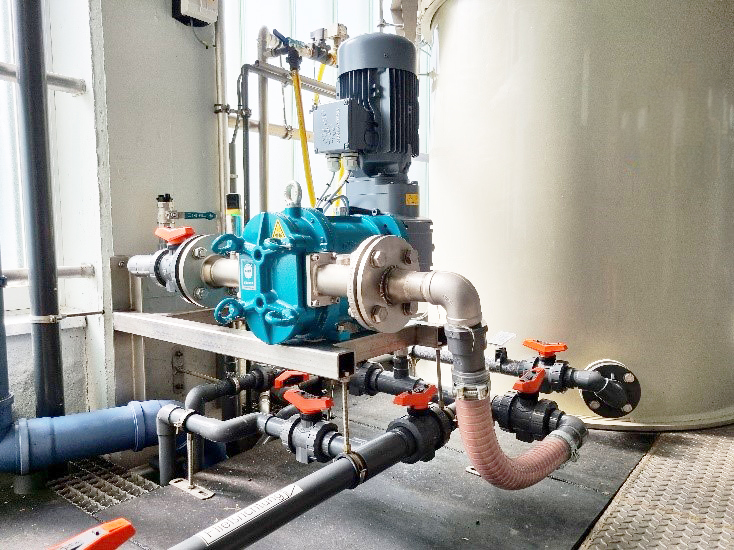

A wastewater manager was looking for a mobile pump for pumping operations at the wastewater treatment plant and for sewer network operations outdoors.

The wastewater treatment plant had acquired a new telescopic loader for loading sewage sludge a few months earlier. Therefore, the idea came up to operate the mobile pump by means of the hydraulic motor on the existing telescopic loader. The rotary lobe pump is mounted on a mobile unit that can be attached to the telescopic loader with an adapter. This way, the mobile pump can simply be transported to the respective sites of operation. The pump is driven by a hydraulic motor.

Hose storage compartments are integrated into the mobile unit. This makes it easy to take suction & pressure hoses to the job site. With the help of the Börger control technology, the pump can also be operated unattended. The level in the respective basin or channel is monitored via a level probe. The control technology switches off the pump if the level falls below the defined minimum level.

Municipal wastewater treatment

Elastomers

The operator of a wastewater treatment plant in Austria uses a BLUEline Nova clean for conveying elastomers. The “clean” version of the Nova pump has no casing protection, so that there are hardly any dead spaces. The pump is driven by a directly mounted helical bevel geared motor, which makes it even more compact.

Municipal wastewater treatment

Wastewater

A large German drainage cooperative uses a Börger mobile pump installed on an L frame for hook-lift trailers for a variety of pumping tasks.

In addition to the pump, the L frame also contains boxes in which hoses, connectors, traffic cones, etc. can be stored. In very confined spaces, the pump and the drive can be removed from the L frame. The flow rate of the rotary lobe pump is infinitely adjustable between 100 and 300 m³/h.

The pump has a suction lift of up to 7 m. This is especially important when emptying deep basins. The pump is driven by a combustion engine that is installed in a noise enclosure together with the pump and the control technology, allowing the pump to be used in residential areas as well. The pump can be controlled very easily via the control technology. Here, a level sensor is installed which allows the pump to work fully independently.

Municipal wastewater treatment

Permeate

A water treatment plant in Bahrain looked for four pumps for conveying permeate. The operator of the plant had only gained experience with centrifugal pumps in this area before. The operator was dissatisfied with the complicated and prone to failure pipeline construction which is necessary so that backflushing through the centrifugal pumps for cleaning the membranes can take place. The customer now uses four Börger rotary lobe pumps in membrane filtration. By changing the direction of rotation, the flow direction can be reversed. That way, the membranes can be cleaned by backflushing with filtered water without the need for a complicated pipeline system with several valves.

Municipal wastewater treatment

Grease trap

A wastewater treatment plant was having problems with impurities and fibers contained in the grease intake trap. This led to more time spent on maintenance and cleaning at a later stage in the plant.

A Börger Multicrusher was installed in the grease trap station in the plant. Using a pressure pipe, the suction unit forces the sludge through the Multicrusher into the wastewater treatment plant. To protect against very large contaminants and impurities, a small stone trap is integrated at the input flange. The Multicrusher also has an autoreversing control unit to protect against sudden jamming of the unit.

Municipal wastewater treatment

Primary sludge

The dry substance content had increased due to a certain process at a wastewater treatment plant. Since then, faults had occurred at several points in the pump due to solids accumulating and blocking the pumps. The blockages were causing frequent damage.

After successfully conducting different tests, they opted for the Börger Multicrusher for dealing with the primary sludge. The Multicrusher was installed on the suction side of the two primary sludge pumps which transfer the sludge alternately.

Operating safety, chopping performance and the reasonable wear parts were decisive in convincing the wastewater treatment operator. Since the Multicrusher was installed, the primary sludge pumps have been running smoothly.

Municipal wastewater treatment

Digested sludge

Contaminated sludge is delivered by tanker trucks to a wastewater plant which is then treated in the facility. The sludge is conveyed under pressure from the tanker into the plant. Due to the very low pressure, solids in the sludge persistently stick in the pipeline and cause it to block.

To chop these solids and prevent more blockages, the operator of the wastewater treatment plant installed a Börger Multicrusher. The Multicrusher is mounted on a hand cart and equipped with a small stone trap for extracting non-floating solids (such as metal parts) and is connected between the tanker truck and the treatment plant.

Since the operator has been using the Börger Multicrusher, there have been no more incidents due to pipe blockages when discharging from the tanker.

Municipal wastewater treatment

Pumping facility

A treatment facility was experiencing persistent problems with a rotary pump in a pumping station.

The communal wastewater is collected in a sedimentation tank. Here the heavier solids fall to the bottom and are removed. A centrifugal pump conveys the wastewater from the tank to a water treatment facility. However, the wastewater still contains solids in the medium that kept blocking the rotary pump.

A solution was needed. A Börger Multicrusher was chosen and installed between the sedimentation tank and the centrifugal pump. Since the Multicrusher has been installed, pump downtime caused by solids has not occurred.

Municipal wastewater treatment

Wastewater treatment facility

A major manufacturer of human waste facilities specialized in the intake of wastewater from areas which are not connected by a sewer system. The wastewater is delivered in tanker vehicles and often contains solids and fibers. Previously, the solids were separated from wastewater by grids. However, blockages kept occurring from the solids, causing more maintenance work. The solids also had to be disposed of separately which presented an additional cost. The operator then decided to chop the solids when wastewater entered the system. By chopping the solids, a higher gas yield could be achieved in the digestion towers as well as having an overall positive biological impact.

The customer chose a Börger Multicrusher to do this. Due to very limited space restrictions in the standardized human waste facility, the Multicrusher had to be very compact. It was decided to run the Multicrusher with a helical bevel geared motor with direct coupling. This had the benefit of being easily maintained. The Multicrusher was also fitted with a stone trap. To avoid any obstinate solids from blocking the chopper, the Multicrusher has reversing control.

The operator of the wastewater treatment facility is very satisfied with the Börger Multicrusher. The customer was particularly impressed by the trouble-free operation and the low-maintenance design of the Multicrusher.

Municipal wastewater treatment

Pumping station

A town had persistent problems with a blocked dirty water pump in a wastewater pumping station. Toilet paper, wet paper and other toiletries accumulated in the channel and were flushed into the centrifugal pump and blocked it when it started to rain. Due to positive experience with a Börger flood pump, the customer opted for a Börger Multicrusher. The dry-installed dual-shaft grinder was mounted into the pipeline of the pumping station in front of the dirty water pump very easily thanks to the very compact dimensions. Since the Multicrusher was installed, the dirty water pump does not block any more.

Municipal wastewater treatment

raw sludge

In a municipal wastewater treatment plant in Sweden a pump conveys the raw sludge from the thickener to a digestion tank.

Inside the pipes, valves and the pump, repeated blockages occurred caused by rags, toiletries and entanglements. A Multicrusher was installed in the pipeline upstream of the pump to macerate the solids. There have been no blockages ever since. The customer is surprised about the low noise level. In addition, the Multicrusher does not have to be removed from the pipeline during maintenance.

If any damage on one of the blades is noted during the maintenance work performed at regular intervals, it is not necessary to replace the entire blade block. The operator can replace the damaged blade only. Despite the demanding application, the Multicrusher has been operating since 2014 with just one blade change.

Municipal wastewater treatment

Thin sludge

This Multicrusher is installed upstream of a decanter. It shreds the solids in the thin sludge and separates impurities.

Before the thin sludge containing solids is sucked through the Multicrusher, it has to pass through the debris collector. Here, solids that cannot be macerated, such as large stones, glass, or metal objects, are separated. Inside the Multicrusher, the rotating blades shred the solids and homogenize the thin sludge before it enters the decanter.

Municipal wastewater treatment

Sludge suction

PTO-operated Rotary Lobe Pumps are mounted on a three-point hitch at a soil and water association to discharge sludge from dredgers and transfer it to fields and pools for draining. The pressure from the vessel's centrifugal pump is sufficient to reach the Börger Rotary Lobe Pump, which then has to convey the sludge up to another 1,000 meters. Since the Börger Rotary Lobe Pumps have been in use, the pumping destinations can be further away and the dredger is able to operate at optimum efficiency.

Municipal wastewater treatment

Power-take-off pump

Mobile, self-priming Rotary Lobe Pump on a three-point hitch with PTO connection for quick use in the event of a flood, canal work, pumping station support, wastewater treatment and for disaster relief. Suction and pressure hoses are installed in just a few minutes. The pumping station which is self-sufficient when connected to a vehicle (such as a Unimog or tractor) is perfectly suited for use in open fields.

Municipal wastewater treatment

Thickened sludge

An eccentric screw pump was installed on the thickened sludge side of a water extraction centrifuge. The maintenance costs were proving far too high for the customer. The pump also had to be completely dismantled for any repair work to be done.

Once the new rotary lobe pump was installed, the pump drive with a frequency converter was controlled by a signal from the sensor (hopper). The auger feed drive is run by a manually adjustable gear motor. This auger feed ensures that the pump always receives the optimum inlet pressure and amount. The steep walls of the hopper also prevent the build-up of sludge.

Municipal wastewater treatment

Digestion tower feeding

The operator of a wastewater treatment plant wanted to store the grease collected in the sand trap in the digestion tower to achieve higher levels of gas production. The grease has different degrees of viscosity and is full of very different types of solids. The customer was looking for a robust and low-maintenance design and technology. Here Börger built a stone trap coupled to a chopper.

The grease/water mixture then flows into a grease container where the mass is kept homogenized by an agitator controlled by a probe. The grease and water mixture is primed from the sand trap by a tanker and taken for removal. Once there, the mixture is pumped through the pipe via the stone trap using the Börger Rotary Lobe Pump in the tanker. The remaining solids are then chopped in the Börger Multicrusher. An additional Börger Rotary Lobe Pump conveys the mixture from the grease container straight to the digestion tower.

Municipal wastewater treatment

Primary clarifier discharging

The dry-installed, self-priming Börger Rotary Lobe Pump extracts the partially thickened sludge from the primary clarifier. The rotary lobe pump has a built-in frequency converter which can adjust the required rated capacity perfectly. The vehicle trailer floor is equipped with grating to ensure the pump is always kept dry. The trailer can be supplied with a tarpaulin and straps and is also part of the Börger product range.

Municipal wastewater treatment

Wastewater pumping

A water treatment facility was having huge problems with an overflowing sewage collection tank in the event of flooding. The water works operator decided to buy a mobile Börger FLA 2072 Rotary Lobe Pump to deal with the problem.

The pump had to be self-priming and dry-run compatible as well as able to achieve a high pump output. It also needed to be resistant to any solids contained in the wastewater. The customer is very satisfied with the Börger pump.

The Rotary Lobe Pump is mounted on a trailer with tandem axle and run with a 45 kW electric motor. The unit is equipped with a frequency converter which controls the speed of the pump and is operated by a potentiometer installed in the control cabinet. This allows the rated capacity to be adjusted.

Municipal wastewater treatment

Membrane filtration

Membrane filtration is a process that uses physical barriers such as water-permeable membranes to separate particles from the water to be purified. A water treatment plant in Beijing uses 14 Börger Rotary Lobe Pumps in its membrane filtration system. The pumps achieve an overall capacity of up to 10,000 m³/h (44,029 usgpm/h). The pumps suck the water to be purified through the membranes. The membranes have ultra-fine pores, through which the water (called “permeate”) can pass. Solids, bacteria, etc. are retained by the membranes and thus separated from the water to be purified.

The membranes are cleaned e.g. by periodic back-flushing with filtered water. For this reason, it was important for the operator of the water treatment plant to use pumps which can be reversed. In addition, the pumps should have high suction capacity. As different quantities are pumped when operated in filtration mode compared to back-flushing mode Börger rotary lobe pumps are operated by means of a frequency converter controlling the pump speed.

The Börger Rotary Lobe Pumps are extremely stable and practically wear-resistant. However, in the event of wear, the low maintenance design of the pump (MIP = Maintenance in Place) enables pump maintenance to be performed by the customer's in-house personnel in a very short time. This keeps downtime and maintenance costs to a minimum.

Municipal wastewater treatment

Grease sludge

A major waterworks company operates a community sewage treatment plant in conjunction with private companies. The grease sludge extracted from the grease trap is drained and transported to the digestion towers at a biological treatment plant.

Here the grease sludge is stored in a heated tank. The grease sludge is heated up to 60-65 °C (140-149 °F) in the tank to keep it sufficiently fluid and thus pumpable. A Börger Rotary Lobe Pump circulates the grease in the digestion tower when required. The tank with the pump is designed as a mobile unit to be used for feeding digestion towers in different operations. The Börger rotary lobe pumps proved extremely beneficial here with its compact, low-on-space design.

The water association is very satisfied with the Börger pump. The reliability of the Börger pump and its long service life made the decision easy for the customer. The water association now uses Börger rotary lobe pumps in several of its treatment plants.

Municipal wastewater treatment

Flood pump on three-point hitch

To respond to a flood quickly and to react independently, a municipal construction yard responsible for flood protection was looking for several mobile pumps. It was important for them to have powerful, mains-free, solids-resistant pumps which could be easily used anywhere. The customer chose three Börger Rotary Lobe Pumps with PTO drive. Besides the proven quality of the Börger Rotary Lobe Pumps and their high performance, it was the easy handling which was the decisive factor for the customer.

Each compact rotary lobe pump is mounted on a three-point hitch. This standard three-point hitch can be mounted on an Unimog truck or a tractor at the front or rear of the vehicle and driven straight to the application site. Sufficient ground and off-road clearance is also provided to be able to drive through flooded or difficult terrain.

As this type of design does not have its own drive or need a chassis, it is a very cost-effective version. The pump is run using the vehicle's PTO. The customer is extremely satisfied with the three Börger mobile pumps and well-equipped in the event of a disaster.

Municipal wastewater treatment

Vacuum dewatering

A manufacturer of vacuum systems was looking for high-performance pumps for vacuum wastewater collection systems. The manufacturer emphasized the need for pumps that are suitable for vacuum applications, have a high suction capacity and are resistant to solids. The customer opted for Börger rotary lobe pumps type PL 200. The customer is very satisfied with the Börger rotary lobe pump. In addition to the high reliability and suction capacity, the customer is particularly impressed by the low energy consumption of the Börger pump.

Municipal wastewater treatment

Tank combination with digestion tower function

A wastewater treatment plant was looking for a stainless steel tank combination for a new technique of gas extraction from digested sludge. Here, a high-level tank should surround an inner cylindrical pipe.

The operator of the wastewater treatment plant decided in favor of a Börger stainless steel tank type 07.8. The customer was not only convinced by the high quality, but also by the possibility to choose the size as well as the material of the tank individually for each application.

The selected tank is 12 m high and consists of 8 stainless steel liner rings. The liner rings 1 – 6 are made from stainless steel 1.4301, because of the anaerobic fermentation of the area, which is covered with medium. Stainless steel 1.4571 has been selected for the two upper liner rings and the roof, as it is more resistant to chemical gases.

The Börger stainless steel high-level tank has been mounted next to the cylindrical pipe, which has already been installed, and has then been lifted over it by crane. With this technique, much time and installation costs could have been saved, because of the better installation conditions.

Municipal wastewater treatment

Anaerobic digestion circulation

In 1999, in a Bavarian wastewater treatment plant, the operator decided to use a Börger rotary lobe pump for digestion tower convection. After the Börger rotary lobe pump had operated 24 hours a day for two years without problems, the treatment plant operator was so impressed that he ordered and used more Börger pumps. The pump from 1999 has operated without problems since then. The other Börger rotary lobe pumps have not failed so far either. The rotors of the pump are equipped with replaceable lobe tips. Only the lobe tips have been replaced since 1999.

Municipal wastewater treatment

Submerged pump for grease sludge

A wastewater treatment plant had persistent problems with a centrifugal pump which was used for pumping grease sludge. The submerged centrifugal pump pumped the sludge from the grease sludge basin into a storage shaft from which a second pump fed a digestion tower with the grease sludge. Higher TS contents caused problems to the centrifugal pump. The recurring blockages of the pump and the complex maintenance work resulting from them were the reason why the operator of the wastewater treatment plant looked for an alternative pump technology.

Following intensive research, the customer decided to purchase a submerged Börger rotary lobe pump. Due to its ability to pump with stable pressure, the Börger rotary lobe pump can convey the viscous grease sludge from the grease sludge basin into the digestion tower directly. A storage shaft and a second pump are not necessary any more.

The customer is very satisfied with the new grease sludge pump. Since the customer has been using the Börger rotary lobe pump there have not been any failures caused by the pump even with high DS contents of the pumped medium.

Municipal wastewater treatment

Tanks in process water and wastewater treatment

One of the most advanced milk powder plants in Europe was looking for three tanks for their in-house process and wastewater treatment. 600 million kg milk is processed in the plant every year.

The manufacturer opted for Börger stainless steel tanks due to the lasting value and long service life. The tanks in segmental design are installed within one week after the base plate has been finished. The tanks have been built in stainless steel 1.4301 and 1.4571 on customer request. The three stainless steel tanks are equipped with a GRP roof. The self-supporting cupola is accessible and offers the highest emission protection. The GRP roof can be installed gas-proof on request.

Municipal wastewater treatment

Leachate

The operators of a landfill were looking for suitable tanks to store the leachate occurring in the plant. The PE tanks used so far had become too small.

The customer opted for three Börger stainless steel tanks. Depending on the rainfall, different amounts of leachate with varying pollutant concentrations occur at the landfill. The stainless steel tanks are lined on the inside with HDPE sheets to protect the stainless steel from the often highly concentrated pollutants. The plastic sheets could be fastened without any problems to the horizontal screw connections.

Thanks to the self-supporting roofs, a roof support was not required, which made laying of the flooring material so much easier. The semi-annual inspections can be carried out quickly and easily through the manholes in the tanks.

Municipal wastewater treatment

Wastewater for MAP precipitation

A wastewater treatment plant was looking for suitable tanks for the precipitation of magnesium ammonium phosphate (MAP) from municipal digested sludge.

Phosphorus is recovered during this chemical process. The customer opted for two Börger stainless steel tanks. They were convinced by the variety of possible stainless steel qualities and the consulting offered by Börger. Following a thorough analysis of the digested sludge composition, the suitable stainless steel and sealant were selected. Thanks to the segmental design, the tanks could be set up very quickly.

They are equipped with an insulation and a multi-colored trapezoidal sheet cladding. The gas-tight stainless steel roof protects the environment from emissions. The 1 m x 2 m (3.3 ft x 6.6 ft) pressure doors allow the customer easy access to the emptied tanks.

Municipal wastewater treatment

Wastewater and activated sludge

During the construction of a new wastewater treatment plant, the requirement was to install different tank variants made of different materials side by side: concrete tanks as in-situ concrete, concrete tanks with prefabricated parts, enamel tanks, wooden tanks and stainless steel tanks. The planning office was looking for a high-quality stainless steel tank to be used as an aeration basin. In addition to recommendations by various wastewater treatment plants, it was Börger’s high flexibility and the willingness to consider special requests that convinced the planning office. Börger stainless steel tanks are perfectly suitable as aeration basins, because the required aeration and agitating systems can be attached to the tank and integrated very well.

The complex staircase system, the pipe bridges and the aeration systems can also be easily attached to the stainless steel tank. Upon the customer’s request, the tank segments were powder-coated in olive green. The requested special height could be implemented without any problems as well.