Food industry

Fruit

A canning factory was looking for a pump system which was able to pump fruit segments (apples, pears and peaches). The eccentric screw pump used previously was having problems coping with the large, hard peach stones in particular. The customer opted for a Börger rotary lobe pump. The Börger Rotary Lobe Pump transfers the by-products, which are sorted manually and transported via conveyor belt to the infeed hopper of the pump. The pump transfers the fruit and the resulting pulp several hundred meters to another part of the plant where fruit juice is produced. The pump and auger are made of stainless steel.

After the success of the Börger Rotary Lobe Pump, the customer then placed another order for two smaller pumps with auger feed.

Food industry

Liquid sugar

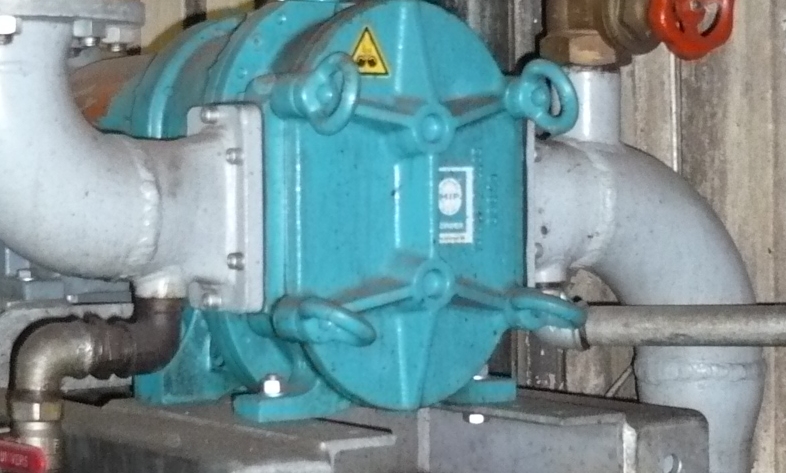

A food manufacturer produces syrups, concentrate, vitamin combinations and emulsions. These raw materials are used in the production of alcohol-free beverages. Liquid sugar is also added to the production process. Different doses of the liquid sugar are fed into a mixing tank depending on the type of drink.

To do this, the beverage manufacturer has been using a Börger Rotary Lobe Pump since 2003. The customer adds the required amounts of liquid sugar using a control panel. A control unit combined with a frequency converter regulates the speed of the Börger Rotary Lobe Pump so that the liquid sugar is pumped out of the storage tank into the mixing tank in doses. The customer is very pleased with the long service life, the low wear and the reliability of the Börger Rotary Lobe Pump.

Food industry

Glucose syrup

Glucose syrup is used as an ingredient in countless food products and beverages and is one of the most important products in saccharification. One of Europe's leading fruit and vegetable producers uses a Börger Rotary Lobe Pump for conveying glucose syrups. The glucose syrup is mixed with other ingredients and then used as a conserving medium for fruit and vegetable preservatives.

The Börger Rotary Lobe Pump transfers the glucose syrup from a storage tank into the mixing unit of the production process.

When selecting a suitable pump, it was essential for the food manufacturer to have one which could handle highly viscous media, guarantee a long service life and be easy to maintain. The preservative manufacturer opted for a Börger Rotary Lobe Pump.

Food industry

Animal blood

At a slaughterhouse, pigs and cattle are killed for food production. The slaughterhouse uses a Börger Rotary Lobe Pump to transfer animal blood.

Once the animals have been slaughtered, the blood drains off in the bleeding zone. A large stainless steel basin is there to collect all the blood flowing from the incision. The Börger Rotary Lobe Pump conveys the blood from a recess in the basin to a storage tank.

The slaughterhouse was previously using a membrane pump to do this. However, the ear tags from the animals kept getting stuck between the membranes and causing damage. The operators at the slaughterhouse sometimes had to open up the membrane several times a day, which cost time and money. The customer is now highly satisfied with the Börger Rotary Lobe Pump. Alongside the pump's resistance to solids and the operation stability, the customer was particularly impressed with the low maintenance.

Food industry

Diatomite

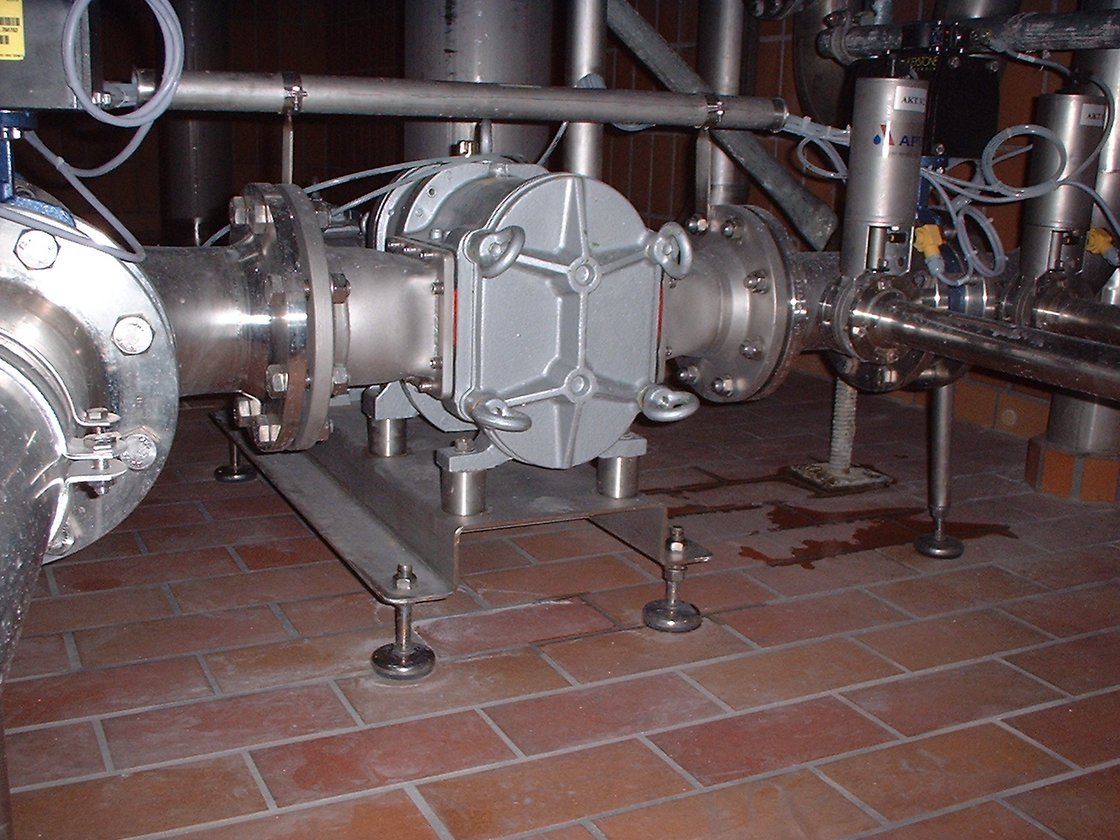

A major German brewery was looking for a pump to transfer liquid containing diatomite. The brewery uses diatomite as a filtering aid. The yeast and turbidity are filtered out of the beer in three phases. In the separation process of the centrifuge, the diatomite filtration is performed followed by filtration through cellulose layers.

To pump the diatomite filtered liquid mixture to a collection tank, the brewery needed a pump. It was important for the brewery to have a robust, high-performance pump. A Börger Rotary Lobe Pump was chosen.

The casing of the Börger pump is made of duplex stainless steel. Due to the extremely abrasive medium, the pump is fitted with replaceable casing protection plates and liners. The Börger Rotary Lobe Pump has been operating at the customer for almost 10 years now. Maintenance work can be performed in a matter of minutes by the brewery's own staff thanks to the low maintenance Börger pumps.

Food industry

Sugar beet

A sugar beet manufacturer was looking for a high-performance pump to transfer cooked sugar beet. The pump needed to be resistant to solids and able to convey high-temperature media. It was essential for the manufacturer to have a pump with high reliability. The customer opted for a Börger Rotary Lobe Pump in stainless steel.

Before the sugar beet is transferred to two stainless steel tanks by an auger unit, soil and other impurities are removed. The beet is heated to 105 °C (221 °F) for approx. 7-8 hours in the stainless steel tanks (excess pressure 0.5 bar (7.25 psi) – so that it cannot start to boil). After the cooking process, the beet slurry containing large pieces of beet is fed to the Börger Rotary Lobe Pump through a special auger.

The Börger pump conveys the unpurified beet slurry into a tank. Then a two-phase decanter is fed by another pump and pure beet substrate is formed.

Food industry

Process water tanks

A major German brewery sought a stainless steel tank for storing the process water needed in the beer production. The brewery had received several offers from various providers. They decided to buy a Börger stainless steel tank with a volume of 856 m³ (226,131 gal).

The Börger stainless steel tank consists of individual segments (1.5 x 3.0 m; 4.9 x 9.8 ft) which are bolted to one another. This system offers distinct advantages over a welded stainless steel tank. Besides the intrinsic value based on it being easy to disassemble and relocate somewhere else, the bolted Börger stainless steel tank is far more reasonable than a welded tank from one of the competitors.

The tank also has a stainless steel roof and floor. As the brewery wanted to clean the tank interior once a year, the Börger stainless steel tank was also fitted with an entrance flap which can be bolted back on firmly after use. The tank takes less than a week to assemble.

Food industry

Intestines

A system supplier for preparation and further processing of organic residues was looking for a compact and robust pump for conveying macerated intestines. Due to the consistency of the intestines, it was important that the pump could convey media with high portions of solids. The customer opted for a Börger Classic PL 300 rotary lobe pump. The customer is very satisfied with the reliability and the efficiency of the Börger rotary lope pump.

Food industry

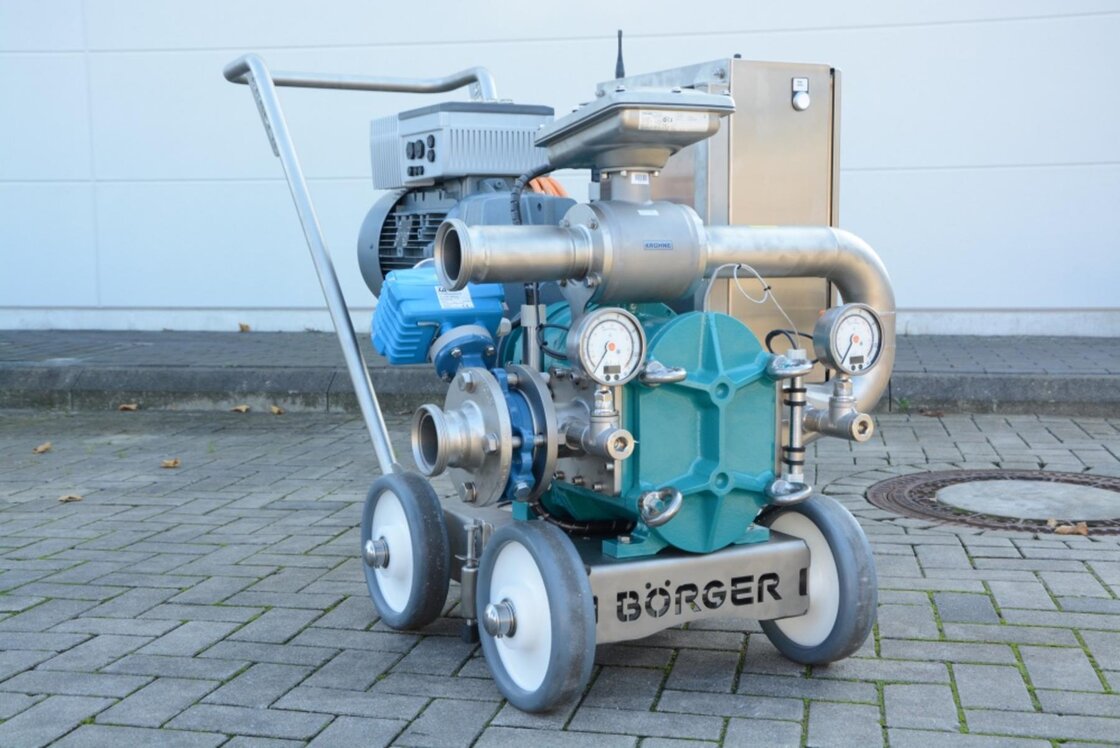

Emptying tanker trucks

A leading provider of gelling and thickening agent for the food and beverage industry processes large quantities of lecithin which is supplied to the company in tanker trucks. Previously a gear pump was used to empty the tanker trucks. As the gear pump had a very high energy consumption but only a moderate flow rate, the customer looked for an alternative pump. In order to be able to use the pump at another location in case of emergency, the Börger rotary lobe pump was built as a hand cart pump. Due to its compact design, the pump can be pushed to the required location like a wheelbarrow. The pump is driven by an electric motor.

Food industry

Lecithin

Lecithin is extracted from the raw vegetable oil in the degumming process of an oil mill by means of a separator. The up to 90 °C (194 °F) hot lecithin mixture is transported to a storage tank. The Börger ONIXline pump conveys the mixture with a viscosity of up to 5,000 mPas in a 35 m (114.8 ft) high tank where it is inserted by means of nozzles. In the process, a pump pressure of approx. 10 bar (145 psi) is created. More or less of the lecithin mixture has to be added depending on the liquid content of the press cake. The pump is operated by a frequency converter. This way, the speed and flow rate can be varied and adapted to the liquid content of the animal feed. The bleaching earth contained in the lecithin mixture is the reason why the medium is abrasive.

Food industry

Process water

One of the most advanced milk powder plants in Europe uses Börger stainless steel tanks for their in-house process and wastewater treatment. The tanks in segmental design are installed within one week after the base plate has been finished. The tanks have been built in stainless steel 1.4301 and 1.4571 on customer request. The three stainless steel tanks are equipped with a GRP roof. The self-supporting cupola is accessible and offers the highest emission protection.

Food industry

Yeast products

A company specializing in the manufacture of yeast products was looking for a reliable and robust pump to convey slurry. The slurry contains potassium sulphate. As a result of extensive tests with pumps from various providers, the customer chose a Börger Select Rotary Lobe Pump with individually pressurized mechanical seals. The customer is extremely pleased with the Börger Select Rotary Lobe Pump.

Food industry

Wine

This mobile hand cart pump is used in a French vineyard for transfer operations.

Thanks to its compact dimension, the pump can also be moved through narrow aisles. The winemaker can set the required flow rate very easily via the control unit. A frequency converter adjusts the pump speed and thus the output. The flow meter measures the exact flow rate. As soon as the required flow rate has been reached, the pump stops and the butterfly valve closes.

The pump is completely made of stainless steel. The screw rotors convey the wine with low pulsation and thanks to the low shear rate especially gentle to the medium so that it does not foam up. Temperature sensors in the pump cover and pressure sensors in the suction and pressure lines ensure the highest level of safety. The pump can be operated via the Börger control unit or the supplied remote control.