Chemical industry

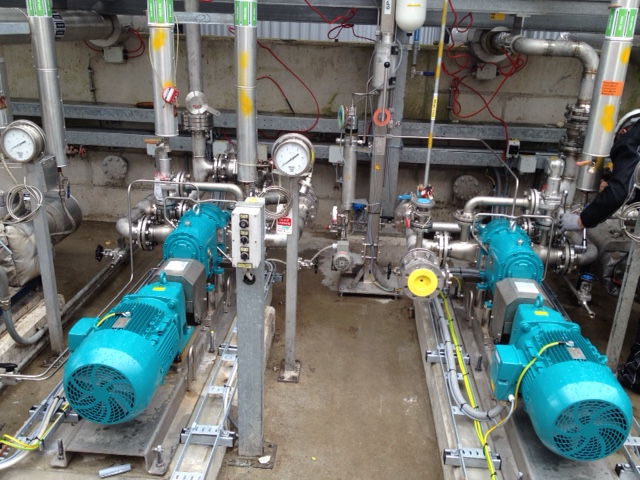

Tristyrylphenol

A chemical company uses two Börger rotary lobe pumps BLUEline Protect for conveying tristyrylphenol. The stainless steel pumps are equipped with double-acting mechanical seals. The Börger rotary lobe pumps empty the arriving tanker trucks and convey the tristyrylphenol to storage tanks. Due to temperature fluctuations of up to 40 °C (104 °F) the viscosity of the medium also varies. The rotational speed of the pumps and the flow rate as a result are adapted to the different viscosities of the medium by a frequency converter. Tristyrylphenol crystallizes when the temperature is below 80°C (176 °F) . For this reason, the pipelines and pumps are heated.

Chemical industry

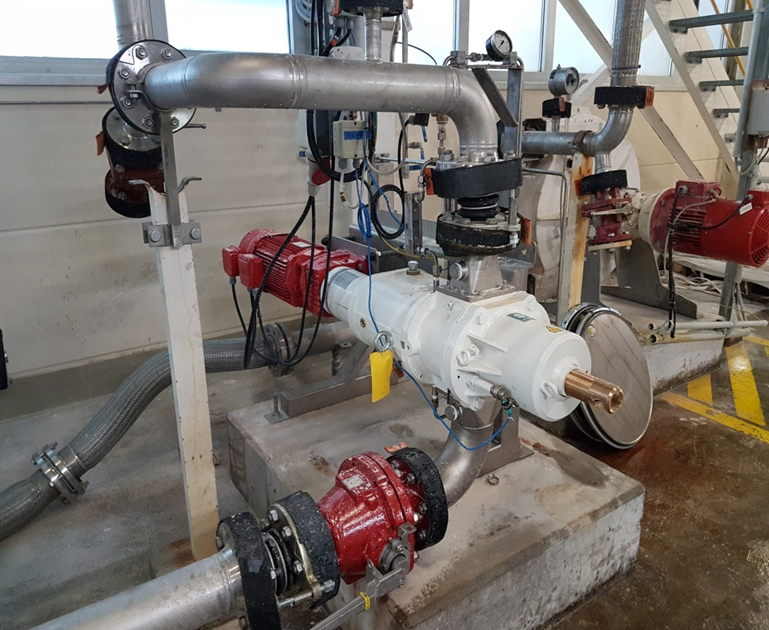

Fatty acid

A company producing lubricants uses an ONIXline rotary lobe pump for conveying fatty acid.

The stainless steel pump is equipped with stainless steel rotors with screw profile. It conveys the fatty acid from the delivery tanker trucks into the storage tanks of the production facility. Since the fatty acid hardens at temperatures below 50 °C (122 °F), the tanker trucks and all pipes are heated. To prevent the medium from hardening inside the pump, the ONIXline is equipped with a heater casing and a heater cover. This way, the pumped medium can be kept at the required temperature also during the pumping process.

The casing and cover are heated by hot water. As an alternative, thermal oil or hot steam can be used.

Chemical industry

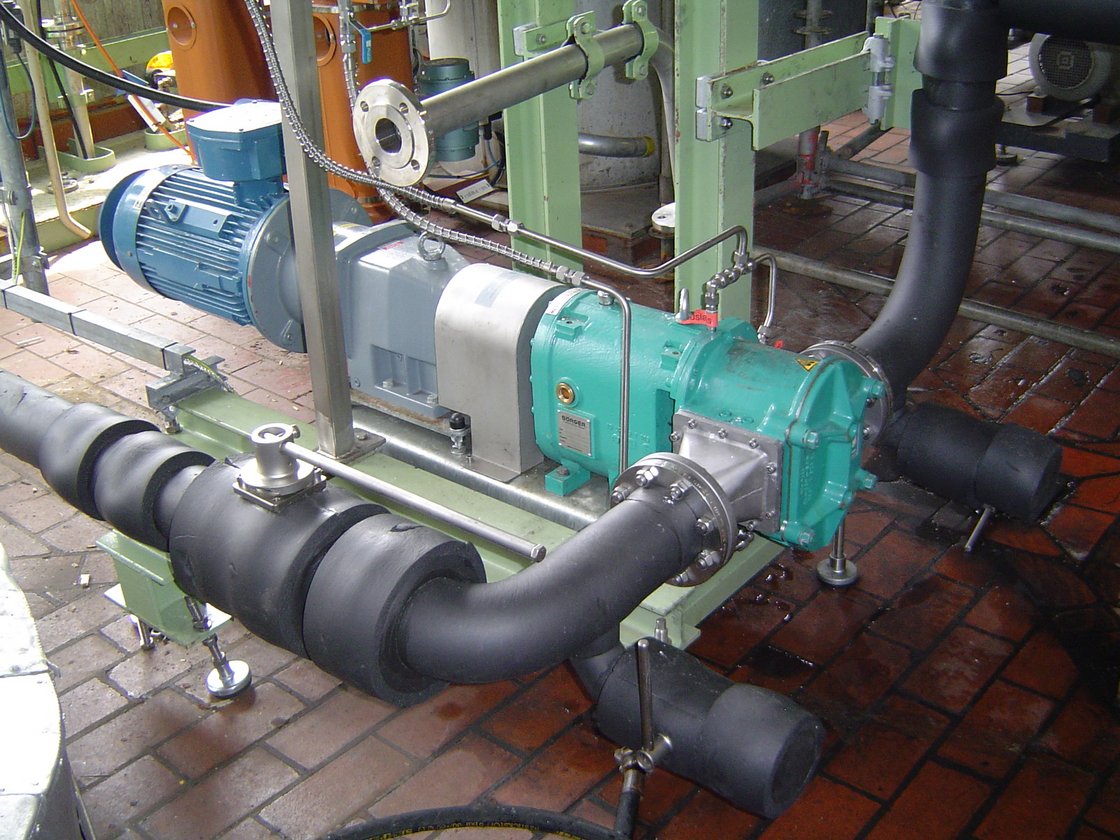

Heat-sealing lacquer

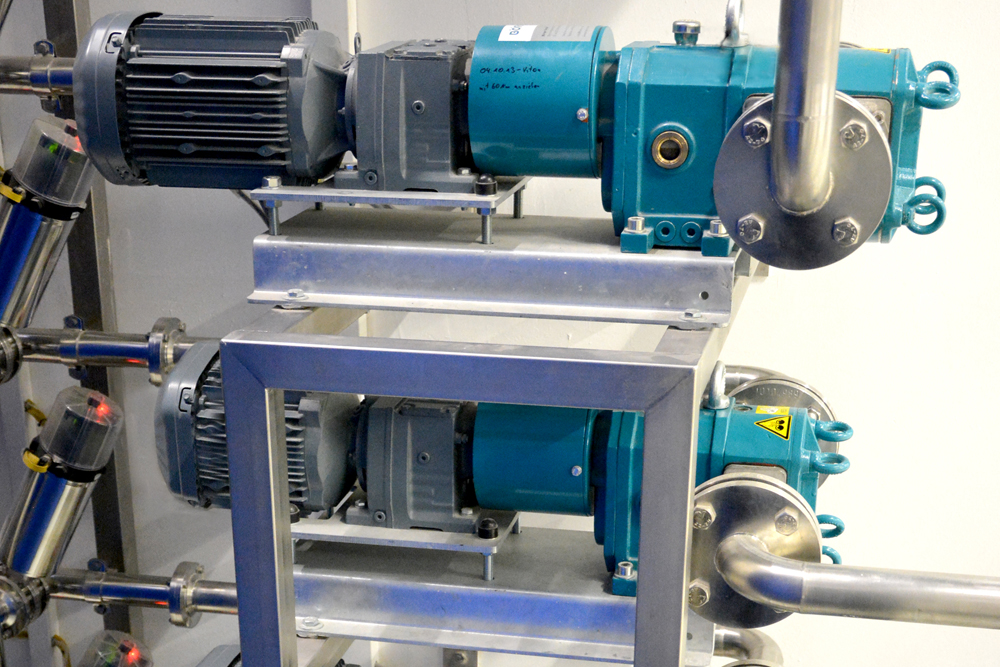

A manufacturer of specialty chemicals uses ONIXline rotary lobe pumps for conveying a polymer solution (heat-sealing lacquer).

The pumps made of stainless steel convey the viscous final product from the production plant through a filtration system and to the storage tank. The medium has a temperature of 80 °C (176 °F) and a viscosity of 6,500 to 8,000 mPas. Due to the viscosity, pressures of up to 11 bar (160 psi) are produced.

The pumps are permanently technically tight pursuant to TA Luft and have an ATEX-compliant design for installation in a potentially explosive atmosphere. The mechanical seals in cartridge design are pressurized via a pressure vessel. The stainless steel rotors with screw profile convey the heat-sealing lacquer nearly without pulsation and very reliably.

Chemical industry

Technical center pump

The technical center of a chemical company uses a Börger mobile pump for conveying aqueous solutions, solvents and fatty acid methyl esters. The Börger control technology controls and monitors the entire mobile unit. The unit is operated by means of an operating device at the ATEX-compliant control cabinet. In order to use the mobile pump in the hazardous area of the technical center in accordance with ATEX regulations, various measuring instruments monitor various parameters of the pump and the drive.

Chemical industry

Suspensions

A chemical company has specialized in the production of additives for the food industry, cleaning agents and paints and lacquers. The company uses a BLUEline Nova handcart pump for conveying different suspensions with viscosities between 100 and 80,000 mPas.

The fluids to be pumped have temperatures between 20 and 95 °C (68 - 203 °F). In order to adjust the speed and, as a result, the flow rate to the properties of the different fluids, the pump is operated via a frequency converter.

Due to the abrasive components in the pumped media, the “tough” version of the stainless steel pump is equipped with stainless steel casing protection plates and liners. In case of wear, the casing protection can simply be replaced. A Variocap protects the pump from uncontrolled pressure surges.

Chemical industry

FCC catalysts

A catalyst producer uses a Börger rotary lobe pump for conveying FCC catalysts.

The pumped medium is very abrasive and quickly forms deposits. To prevent the formation of deposits, the pump is installed turned 90°. The pump is equipped with a pressure switch and a Variocap. The double-acting mechanical seals installed are pressurized by a barrier pressure system provided by the customer. The service life of the pump is significantly longer than that of the peristaltic pump used before.

Chemical industry

Pesticides

A customer manufactures active ingredients for pesticides in batch production: herbicides, fungicides and insecticides. The active ingredient is spun into crystals or liquid in centrifuges. This is where the Börger Protect Rotary Lobe Pump is used.

In the start-up phase of the centrifuge, the ATEX compatible Börger Protect has to achieve a high pump output. After filling, the pump is run via a bypass to prevent crystallization in the pipeline. Here, the pump operates with less power. Other pumps showed poor results with regard to the high temperatures and the crystals. This active ingredient is processed into the finished product in a downstream operation using Börger Rotary Lobe Pumps again (4 x Börger Protect) as well as a dispersing machine.

Chemical industry

Slime

Slime always occurs in the production of biodiesel and is removed, stored and pumped into tankers by decanters. The self-priming feature of the Börger Rotary Lobe Pump supports and assures the smooth flow of slime. It will not be affected by any change in the viscosity. The wetted parts of the Börger Rotary Lobe Pump is able to withstand temperatures of up to 125 °C (257 °F). Due to the use of solvents here, the Börger Rotary Lobe Pump is compatible with ATEX standards.

Chemical industry

Sodium sulfate

The customer runs an amine recycling plant. The amine sulfate delivered is processed in a rectification system. Caustic soda reacts with the sulfuric acid contained in the amine sulfate. The result is a sodium sulfate solution which is pumped into a storage tank. The Börger Protect Rotary Lobe Pump is used in the neutralizing process by adding sulfuric acid. The Börger pump conveys the sodium sulfate solution from the storage tank through a pipe system back to this storage tank. In the meantime, sulfuric acid is mixed in on the suction side. A pH value can be measured using a meter attached to the pressure side. This procedure is repeated until the sodium sulfate solution indicates a pH value of 7.

The eccentric screw pump previously used kept having problems with the sealing. As the air quality control requirements are applicable here, the Börger Protect Rotary Lobe Pump was selected. The barrier pressure was set to 8 bar (116 psi) in the thermosyphon tank. If the pressure drops below 5 bar (72.5 psi), a pressure switch turns off the system. The medium pressure is restricted to a maximum of 3 bar (3.5 psi) by a pressure transducer. This ensures a minimum barrier pressure of 2 bar (29 psi) above pump pressure.

Chemical industry

Natural latex

A positive displacement pump was needed that could handle natural latex with care. The temperature of the medium is not permitted to exceed 25 °C (77 °F) while pumping due to the risk of coagulation. The previous membrane pump frequently clogged and suffered from wear on the inlet and outlet valves.

A Börger Rotary Lobe Pump was equipped with a cooling system and installed. The Börger Rotary Lobe Pump with its gentle pumping and the cooling system ensures that the medium has an optimum temperature and that the system runs smoothly.

Chemical industry

Hydrogen peroxide

A chemicals provider needed a pump for installation on a tanker vehicle. The pump needed to convey hydrogen peroxide from a 1000 liter IBC tank (Intermediate Bulk Container) to the storage tank of the tanker vehicle. The same pump should also be able to discharge the storage tank again.

The pumped medium places heavy demands on the pump and the materials used in the pump. In addition, hydrogen peroxide is very sensitive to contaminants (particularly metal).

The customer opted for a Börger Rotary Lobe Pump. Due to the wide range of material options, Börger built the ideal reversible rotary lobe pump for this particular application.

Chemical industry

Soap

A manufacturer of oleochemicals and additives was looking for a reliable pump for liquid detergent. Vegetable or animal fats are mixed with caustic soda and several other ingredients and homogenized in a mixer for making detergent. This mixture is then pumped to a reactor where a reaction occurs with the individual additives. This takes place at temperatures of approx. 120 – 130 °C (248 - 266 °F).

The previously installed rotary piston pump had cavitation problems at high speed and also caused severe vibration. The packing mechanical seals suffered leaks within a few days and had to be repaired and repacked which meant shutting down the plant.

The customer now uses a Börger Protect Rotary Lobe Pump. The Börger Protect is equipped with double-acting mechanical seals. These are pressurized via a thermosyphon system. The thermosyphon tank is cooled using an internal cooling coil and the temperature is dissipated via a heat exchanger. The pumped medium is not allowed to cool down during the process. The pipes on the suction and pressure side are heated. The Börger Rotary Lobe Pump was fitted with a steam heating cover which heats the pump casing. This way, it keeps the medium at the required temperature while pumping. The task of the Börger Protect is to circulate the medium in the reactor until a complete reaction has taken place. The plant is operated 24 hours/day.

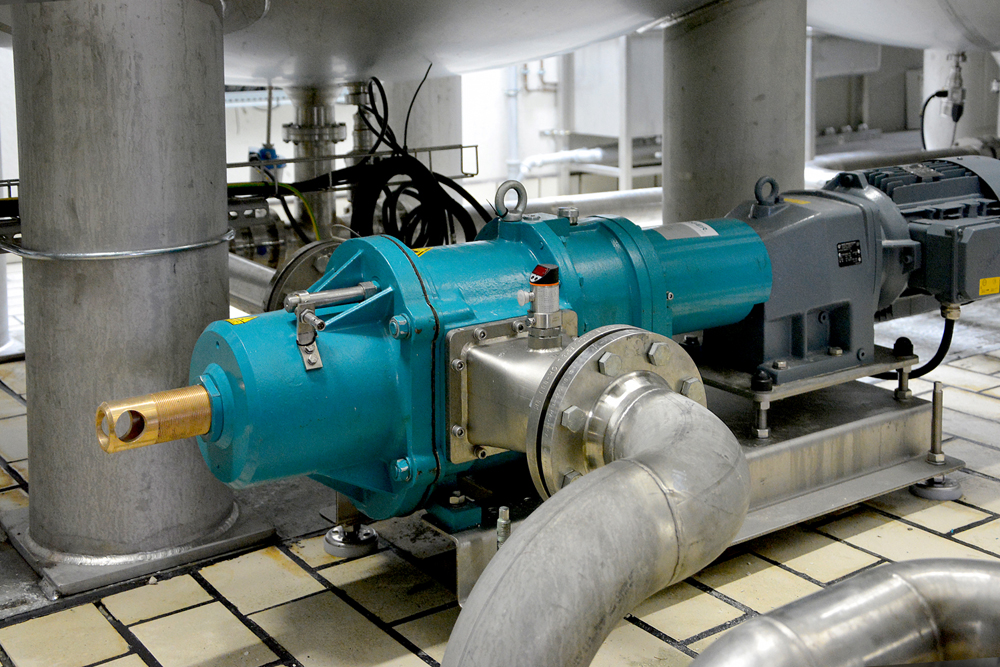

Chemical industry

Glycerine residues

A manufacturer of oleochemical additives and consumables was looking for a pump for conveying glycerine residues. Due to the viscosity and the high solids content of the medium, the centrifugal pump used so far had cavitation problems and, as a result, generated strong vibrations and running noises. Severe damage was caused to the mechanical seals and the impeller. The customer now uses a Börger Protect Rotary Lobe Pump. The machine unit is operated continuously for 24 hours/day. During the process, the medium to be conveyed has a temperature of 80 to 145 °C (176 - 293 °F) and must not cool down. The suction- and pressure-side connections are heated. The Börger rotary lobe pump is equipped with a steam heater cover. It heats the pump casing.

Chemical industry

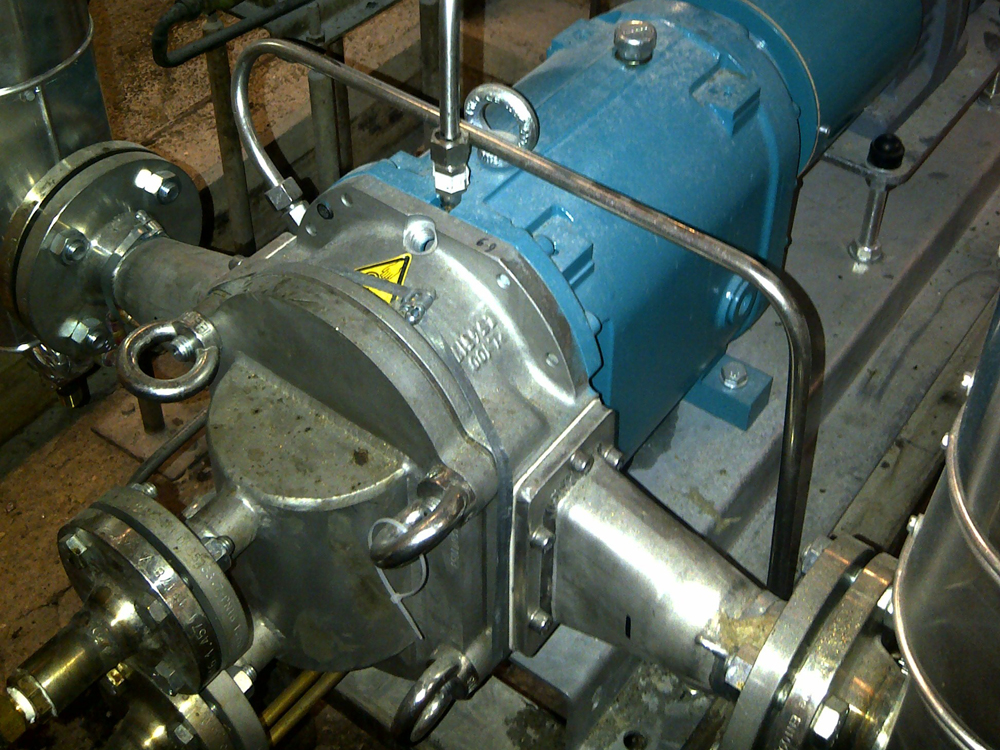

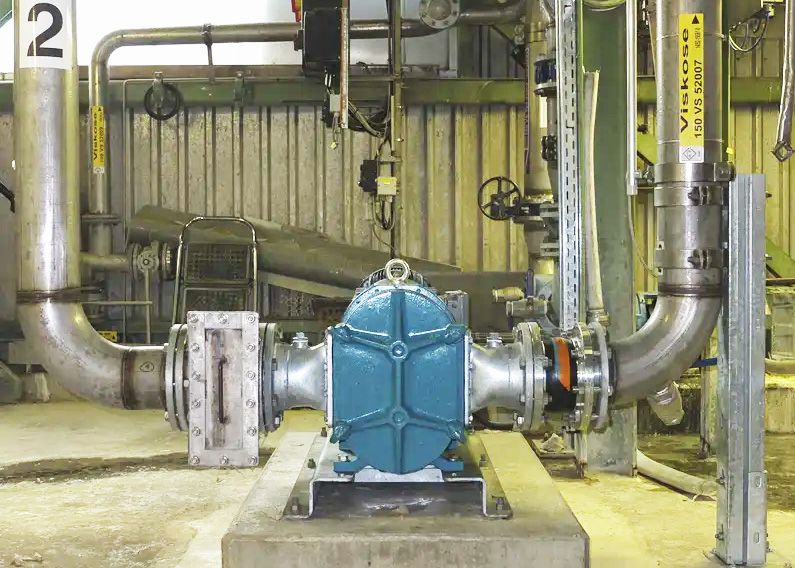

Viscose

A leading manufacturer of viscose special fiber, for use in medicine, for textile and hygiene applications or for special paper, was looking for a reliable pump for conveying viscose. Technical problems of the gear pump used frequently led to delays in the production process. The new Börger pump is equipped with a single-acting mechanical seal with O-rings made of fluoroelastomers. A quench chamber filled with hydraulic oil lubricates the mechanical seal and dissipates any developing heat from the seal. Air cannot come into contact with the seals due to the quench reservoir. Thus, crystallization of the viscose is not possible.

Chemical industry

Soapstock

A company that has specialized in processing oleochemical raw materials uses a Börger rotary lobe pump for conveying soapstock. As the medium has a tendency towards hardening when the temperature is below 50 °C (122 °F), the pump was equipped with a heatable pump casing. In order to protect the pump from excessive pressure caused by the reduction of the pipe cross section (due to residues), the pump is equipped with a Variocap. If the pressure exceeds the predefined working pressure, the Variocap opens. The pressure is equalized due to the pumped medium flowing back. The Variocap closes automatically due to the pressure decrease.

Chemical industry

Cleaning agent

A manufacturer of high quality cleaning agents has only been using Börger rotary lobe pumps for conveying its cleaning agents since 2010. The pumps are used for raw material extraction, in the production area and for feeding the filling systems. In the process, gentle pumping of the cleaning agents is very important as otherwise they might foam up and cause problems with the filling operation.

Chemical industry

Detergents

A large manufacturer of detergents and cleaning agents uses Börger rotary lobe pumps for feeding its filling installations. The prepared detergents and cleaning agents are transported from the manufacturing area to the different storage tanks. The Börger rotary lobe pump conveys the final products with a viscosity of up to 3,000 mPas from the tanks into the filling lines. The rotational speed of the pump and the flow rate as a result are adapted to the filling process by means of a frequency converter. The pump has an ATEX-compliant design. Various parameters of the pump and drive are monitored by means of several measuring instruments which transmit them to an ERP system.