Marine & offshore

Oil/water mixture

Several Börger rotary lobe pumps are installed on a special purpose vessel for combatting oil pollution.

The pumps suck the oil/water mixture from the surface using skimmers. The rotary lobe pumps are particularly suitable for this application because they are self-priming and able to handle entrained air. They pump the oil/water mixture very gently, nearly without emulsification into the separation unit. This facilitates the separation of oil and salt water. The pump chamber is made of stainless steel to be resistant to the seawater. In addition, a stainless steel casing lining protects the pump chamber against solids or abrasive components in the pumped medium.

Furthermore, the Börger pumps are used to pump the separated oil from the vessel when it is in the port. The oil has a viscosity of up to 50,000 mPas. Therefore, the pump operates at a reduced speed. As the Börger pumps can also be operated in reverse mode, the pipe layout on board could be very simple with minimum space requirements.

Marine & offshore

Sludge

A mobile Börger hand cart pump is used on an oil platform to convey various types of oil sludge. The powerful pump is installed on a very compact hand cart frame. This way, the pump can also be pushed through the narrowest aisles of the offshore platform. A hydraulic motor drives the pump. The flow rate is adapted flexibly to the corresponding pumped medium. The entire unit is ATEX compliant.

The Black Protection surface treatment protects the pump casing against the seawater salts. The stainless steel casing lining protects the pump casing against the abrasive components of the oil sludge.

Marine & offshore

Food waste

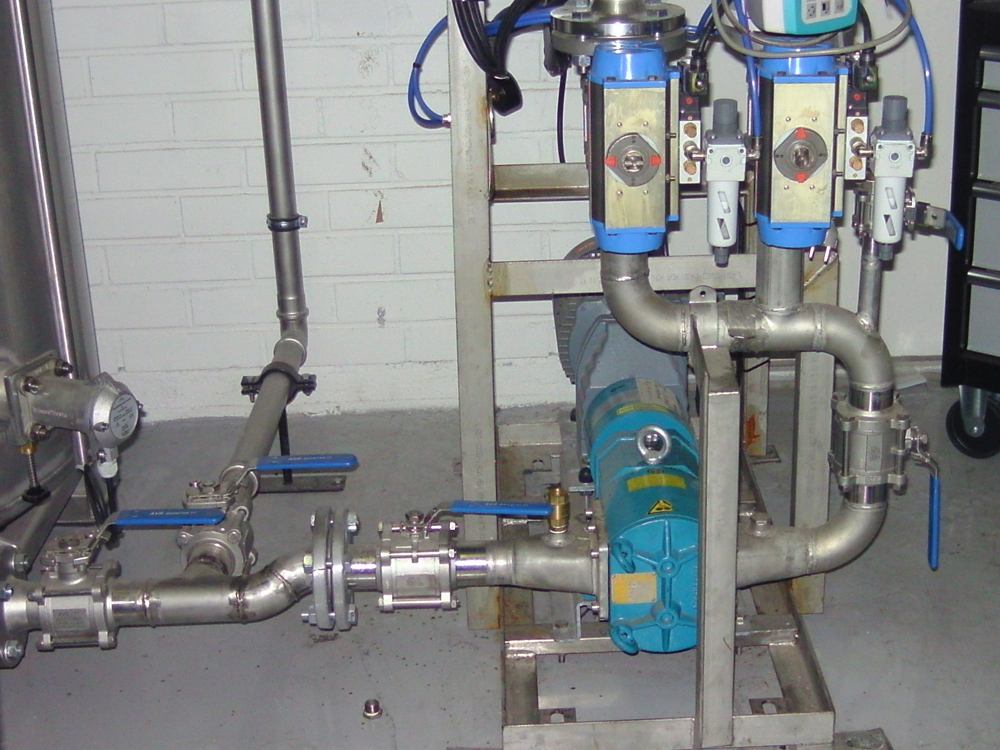

A space-saving combination of a Börger Rotary Lobe Pump and a Multicrusher is used on a cruise ship to convey and macerate food waste.

Despite the confined space on board, all maintenance work can be done at the installation sites of the pump and the macerator without removing them. The customer especially liked the option to replace individual blades instead of the entire blade block of the macerator during maintenance. A debris collector is installed upstream of the Multicrusher. Here, objects that cannot be shredded, such as cutlery or bones, are collected.

Marine & offshore

Bilge, dirty water

Several years ago, some battleships of a European country were modernized. Part of the modernization was the overhaul of the water treatment system. Now the navy relies on Börger rotary lobe pumps and macerating technology.

The compact, space-saving design, the reliability, the low energy demand and the ease of maintenance of the Börger technology were decisive factors for the navy. The pumps are used, for example, to convey bilge and dirty water. They pump the media to be cleaned into the water treatment system. During the neutralization, the wastewater is pumped through the Multicrusher to homogenize it and to macerate the solids.

Marine & offshore

Reject water

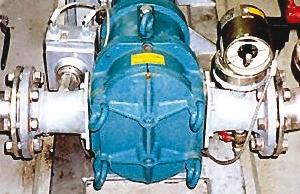

One of the largest shipbuilding companies in the world uses Börger rotary lobe pumps to convey the most diverse fluids. The shipbuilder uses BLUEline Nova pumps for pumping reject water.

In addition to the high flow rate with a very compact design, the high volumetric efficiency of the new pumps was a crucial factor for the customer. The casing plates and liners protect the pump against solids in the medium and are perfectly integrated into the pump casing in a flow-optimized design. Thanks to the innovative fastening system, the Nova pump ensures excellent efficiency also with casing plates and liners installed.

The two Nova pumps are installed turned 90°. Considering the limited space available on board the ships, this reduces space requirements even further.

Marine & offshore

Ballast water

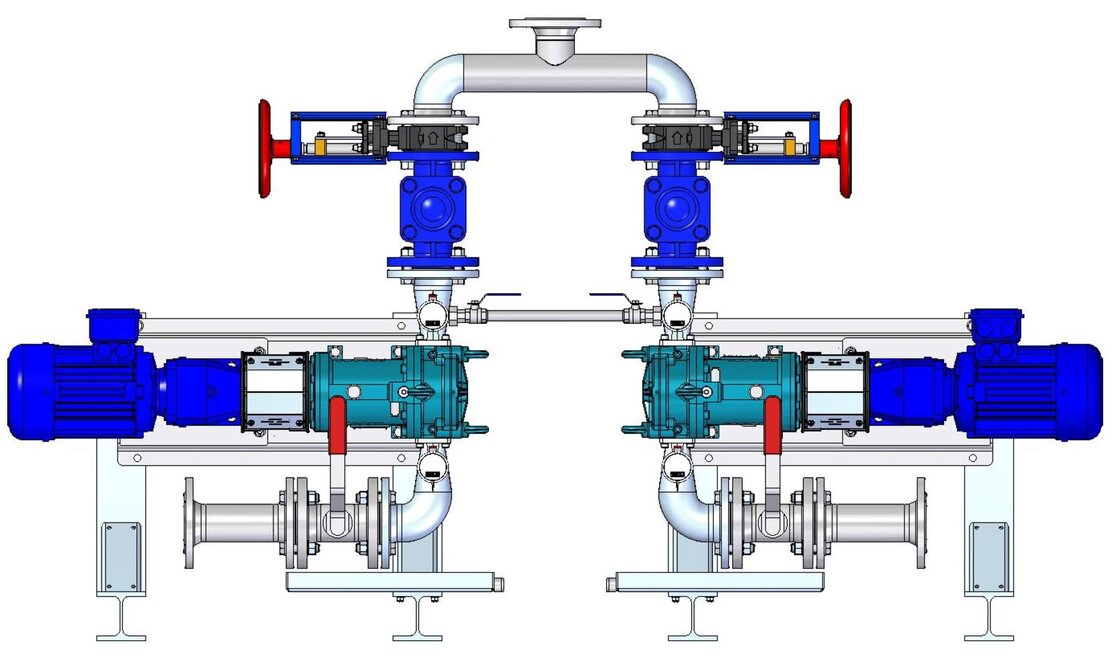

Ballast water is used for balancing purposes to stabilize ships. Once a ship has been relieved of its cargo, ballast water is pumped into respective tanks. When the ship is loaded up again, the water is pumped back to sea. This is performed by ballast pumps. Compared to centrifugal pumps, Börger Rotary Lobe Pumps have the advantage of being able to both fill and discharge tanks simply by reversing the direction of rotation. No extra control units are necessary. The rotary lobe pump is self-priming and dry-run capable. The pumps are frequency-regulated for more precise balancing of the ship. The pump installation is on deck as an ATEX standard.

Marine & offshore

Kitchen waste

A Finnish company that has specialized in systems for waste disposal on ships has been applying Börger rotary lobe pumps for years to convey food waste on ships. The Börger pumps are used in a vacuum system which conveys kitchen waste only. Meanwhile, more than 40 units are in operation. The food waste is filled into a hopper in the commercial kitchen. Due to the rotation of the rotors, the Börger rotary lobe pump generates a vacuum and thus sucks the food waste from the commercial kitchen into a storage container. When in port, the Börger pump is used to empty the storage container.

Marine & offshore

Removal of residues

A shipping company uses Börger pumps on its 3 oil product tankers for draining the pipe systems. The pumps are self-priming, not sensitive to dry running, and can cope with high pressures and changing pumped media without problems. As the pumps are installed on deck, an explosion-proof design was required. The customer is very satisfied with the high reliability and the good suction behavior of the Börger pumps.

Marine & offshore

Bilge

A multi-purpose vessel operated by the Federal Waterways and Shipping Administration is used for laying and collecting light buoys, icebreaking, firefighting, emergency towage and vessel traffic monitoring but also operates as a spillage incident vessel. To this end, the vessel with a length of 78.91 m (358.9 ft) is equipped with two skimmer arms, which – in case of accidents – can absorb the oil/seawater mixture from the water surface. Then the oil is separated from the seawater in the onboard separation system. This separation system is also used for processing the bilge water. To this end, a Börger rotary lobe pump conveys the bilge into the separation tank.

Marine & offshore

Oil recovery vessel

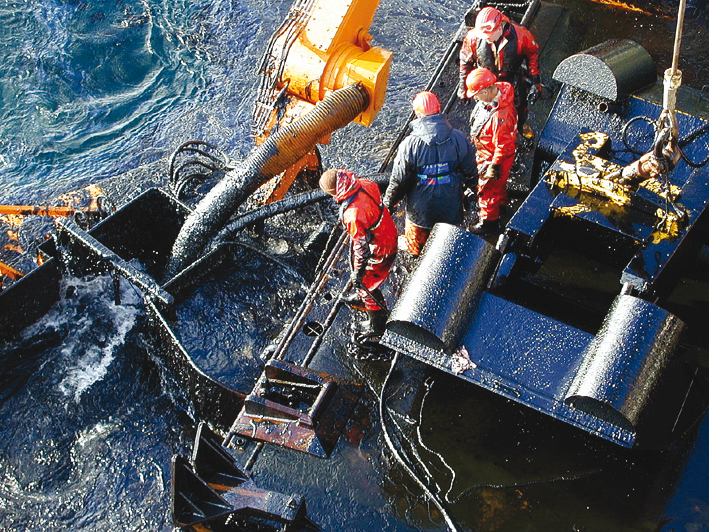

Again and again oil spill emergencies happen on the oceans causing significant damage to the environment. Skimmer pumps convey the oil/seawater mixture into the onboard separation system. For this pumping task it is important to use reliable, high-performance pumps. Since 1996, Börger rotary lobe pumps have been used as skimmer pumps on an oil recovery vessel. The pumps were configured and built individually for the application requirements. The pump casing was manufactured from stainless steel due to the aggressive salt water.

Marine & offshore

Raw oil

A severe problem when fighting oil spill emergencies is the limited capacity of the tanks on the oil recovery vessels. In order to use the tank capacity as efficiently as possible, the oil recovery vessel is equipped with its own separation unit. A Börger rotary lobe pump conveys the oil from the water surface of the collecting tank into the oil storage tank. The separated water can be discharged into the sea. The Börger oil pump was installed on the vessel in 1996 and has been conveying the crude oil without any problems since then.

Marine & offshore

Skimmer pump

A shipyard was looking for a skimmer pump for an oil recovery vessel which could meet the increased requirements. Based on the consistently positive experience with Börger products on other vessels, the Börger rotary lobe pump was taken into consideration. The capabilities of the Börger rotary lobe pump when pumping highly viscous oil and sea water mixtures were tested and approved. Further requirements were the temporary suction of air (dry run), the flow rate of foreign bodies (e.g. dead birds), as well as a possible change of the direction of rotation.

Marine & offshore

Sea water

In order to fix working platforms or wind turbines on the high seas, suction piles are frequently used which can also serve as a foundation. The piles mostly made of steel have a cylindrical shape and are open on one side. With the open side pointing downwards, the suction piles are sucked into the seabed due to the creation of a vacuum and then hermetically sealed. In order to create this vacuum, the seawater situated in the cylinder is pumped from the suction pile. Two Börger pumps are installed on a submersible module and driven by a hydraulic motor. In order to increase the resistance of the pump casing to the aggressive seawater, Börger has developed the Black Protection surface treatment.

Marine & offshore

Food waste

On 01 January 2013 the revised annex V of the MARPOL convention for the prevention of pollution by garbage from ships entered into force. According to the annex, the discharge of all garbage into the sea is prohibited. Comminuted food wastes capable of passing through a screen with openings no larger than 25 mm (0.98 inch) may be discharged into the sea under certain circumstances. For macerating the food wastes, the customer uses a Börger Multicrusher Ocean installed in a 90° turned position. At the top opening, the kitchen waste is fed through a hopper. A special "tamping arm" is used to feed the solids to be macerated completely.

Marine & Offshore

Marine & offshore

The unproblematic pumping in slurp operation, the short-term dry-run capability and the gentle pumping nearly without emulsification are the reason why Börger pumps are the ideal pumps for any oil spill emergencies. The aluminum pump with the 7.3 kW combustion motor is designed as a portable unit for use as a mobile skimmer pump. This way, fully independent operation even in rough terrain is possible. The flow rate can be varied and adapted to the different conditions by means of the pump speed.

Marine & offshore

Sea water with crude oil

A coastguard ship is equipped with Börger pumps to control damage in the event of an environmental disaster by priming oil spills from the sea surface. The water/oil mixture is separated on board and the clean water is then fed back into the sea. Downtime during a crisis is out of the question and the pumps have to be resistant to sea water and reversible.

Marine & offshore

Human waste with sea water

A shipyard decided on Börger pumps for the disposal of human waste on board. Their benefits: low weight, compact design, ease of maintenance and a high degree of safety with the pressure control device. The toxic mixture of human waste and sea water requires a stainless steel liner liquid pump.

Marine & offshore

Wastewater

The ship of a disposal company for ship generated waste was equipped with a Börger Rotary Lobe Pump with variable-speed motor to dispose of waste from large ships. Bilge, oil and sea water subject the material to extreme wear, nonetheless the ease of maintenance and reliability/dependability of the Börger Rotary Lobe Pumps prove their excellence.