Rotor variety

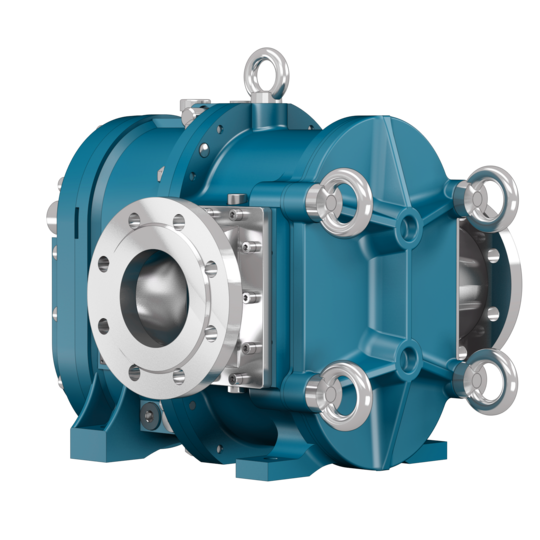

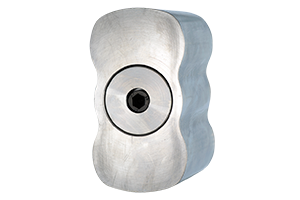

Unique throughout the world: the wide variety of rotors

Up to 8 different rotors in various geometries and materials are available for each pump size. The special design ensures that the sturdy rotor core and the shaft remain untouched by the pump medium at all times. The lobe tips of our unique rotors can be replaced individually which saves time and money.

Rotor variety

A perfect rotor for each application

Every pumping task is different. Due to the many different factors, such as solids content, differential pressure, suction height, etc., selecting the right rotor is very important. There is a large selection of rotors in different geometries and materials for the BLUEline Legend pumps.

The BLUEline rotary lobe pump has been used successfully in different sectors for many years. The highest reliability and the long service life of the pump convince our customers.

Pump performance curves provide information about the efficiency of a pump. The flow rates of Börger rotary lobe pumps remain virtually constant even in case of increasing pressures.

BLUEline series Pump size | Min. Speed in rpm | Max. Speed in rpm | Min. in usgpmFlow rate | Max. in usgpmFlow rate | Max. Pressure in psi | Max. Temp. in °F | ||

|---|---|---|---|---|---|---|---|---|

| PL | PL 200 PL 300 | 1 1 | 700 700 | 0.5 0.7 | 335 500 | 115 60 | 392 392 | PL 200 PL 300 |

| CL | CL 390 CL 520 | 1 1 | 600 600 | 1.0 1.4 | 620 825 | 115 60 | 392 392 | CL 390 CL 520 |

| FL | FL 518 FL 776 FL 1036 | 1 1 1 | 600 600 600 | 1.5 2.3 3.0 | 905 1,365 1,805 | 175 115 60 | 392 392 392 | FL 518 FL 776 FL 1036 |

| EL | EL 1000 EL 1550 EL 2250 EL 3050 | 1 1 1 1 | 600 600 600 600 | 2.7 4.1 5.4 8.2 | 1,635 2,455 3,265 4,900 | 145 75 45 30 | 392 392 392 392 | EL 1000 EL 1550 EL 2250 EL 3050 |

| XL | XL 1760 XL 2650 XL 3530 XL 5350 | 1 1 1 1 | 450 450 450 450 | 4.6 7.0 9.2 14.1 | 2,090 3,150 4,160 6,335 | 145 85 60 30 | 392 392 392 392 | XL 1760 XL 2650 XL 3530 XL 5350 |

FCC catalysts

A catalyst producer uses a Börger rotary lobe pump for conveying FCC catalysts.

The pumped medium is very abrasive and quickly forms deposits. To prevent the formation of deposits, the pump is installed turned 90°. The pump is equipped with a pressure switch and a Variocap. The double-acting mechanical seals installed are pressurized by a barrier pressure system provided by the customer. The service life of the pump is significantly longer than that of the peristaltic pump used before.

Lubricating oil

An Italian power company uses recycled fuel to produce electricity.

The fuel supplies the energy for a 15,000 hp diesel engine which drives a power generator. Two rotary lobe pumps ensure that the engine is constantly supplied with oil. One of the pumps circulates the oil continuously, cooling and lubricating the engine. To this end, the oil is pumped through a filter system and a heat exchanger, which regulates the temperature of the lubricating oil.

The other pump serves as a spare pump, so that engine cooling can be ensured also during maintenance. Due to the confined space, the pumps are arranged vertically.

Boiled starch

A manufacturer of corrugated base paper has been using a Börger rotary lobe pump for conveying boiled starch.

Following a procedure conversion, the starch can reach temperatures of up to 248 °F (120 °C) and has a solids content of 17 %. In the eccentric screw pump used before, the starch was not allowed to exceed a maximum temperature of 176 °F (80 °C) and the pump suffered from excessive wear. The rotary lobe pump used now is completely made of stainless steel. Casing protection plates and liners made of stainless steel protect the pump casing from wear and the pump is equipped with tri-lobe screw rotors made of stainless steel. These rotors convey the boiled starch with very low pulsation.

Oil/water mixture

Several Börger rotary lobe pumps are installed on a ship specially built to combat oil spills.

The pumps suck the oil/water mixture from the surface using skimmers. The rotary lobe pumps are particularly suitable for this application because they are self-priming and able to pump in slurp operation. They pump the oil/water mixture very gently, nearly without emulsification into the separation unit. This facilitates the separation of oil and salt water. The pump chamber is made of stainless steel to be resistant to the seawater. In addition, a stainless steel casing lining protects the pump chamber against solids or abrasive components in the pumped medium.

Furthermore, the Börger pumps are used to pump the separated oil from the vessel when it is in the port. The oil has a viscosity of up to 50,000 mPas. Therefore, the pump operates at a reduced speed. As the Börger pumps can also be operated in reverse mode, the pipe layout on board could be very simple with minimum space requirements.

Wastewater

The wastewater management department of a municipality was looking for a powerful mobile disaster relief pump. They opted for a high-performance Börger pump installed on a hookloader frame.

The rotary lobe pump is driven by an electric motor. The power required is produced by an emergency power generator, which is also installed on the L frame. This has the advantage that the pump can operate fully independently. In addition, the emergency power generator can be used independent of the pump to supply power to the municipal buildings in case of a power failure. In this case, it is possible to remove the pump with the electric motor and the control unit from the L-frame and to use them in a different location. The hookloader frame is equipped with numerous storage compartments and hose holders in line with the requests of the local authority. Roller shutters protect the mobile unit against vandalism.

The pump can be operated via the Börger control technology. In automatic mode, the pump is controlled via a fill level sensor. The pump regulates itself via the intelligent pump control system. The control technology is equipped with a remote monitoring function. A visualized pump control system allows the operator to monitor all operating states of the pump via cell phone, tablet or PC, even from home.